INTRODUCTION

In accordance with the requirements of Order of the Ministry of Energy of Russia dated January 13, 2003 N 6 “On approval of the Rules for the technical operation of consumer electrical installations,” non-electrical personnel performing work that may pose a risk of electric shock are assigned Group I for electrical safety.

Non-electrical personnel of an organization are personnel who, during their working hours, use lighting, heating electrical appliances, personal computers and other office and household appliances (hereinafter referred to as electrical appliances), the operation of which may result in electric shock. The list of professions and jobs related to non-electrical personnel for assignment to Group I for electrical safety is approved by the head of the organization.

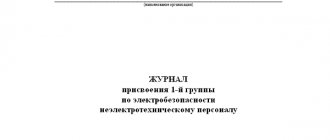

Assignment to group I is made through instruction, which ends with a knowledge test in the form of an oral survey and (if necessary) a test of acquired skills in safe working methods or providing first aid in case of electric shock. The assignment of electrical safety group I is carried out by an employee from among the electrical technical personnel of the organization with an electrical safety group of at least III. The assignment of group I for electrical safety is documented in a journal of the established form.

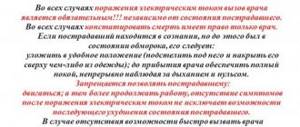

Electrical safety training is carried out at least once a year by familiarizing non-electrical personnel with the following text.

GENERAL REQUIREMENTS

1.1. Electrical safety group I applies to non-electrical personnel performing work that may pose a risk of electric shock. 1.2. Assignment of group I in electrical safety is carried out in the form of a briefing, which must end with a test of knowledge in the form of an oral survey and (if necessary) testing of acquired skills in safe ways of working or providing first aid in case of electric shock with registration in the Logbook for assignment of group I in electrical safety. 1.3. Assignment of group I is carried out by an employee from among the electrical technical personnel with a group not lower than III, appointed by order of the head of the organization. 1.4. Persons with electrical safety group I must have an understanding of the dangers of electric current, safety measures when working with electrical equipment, know and practically provide first aid in case of electrical injury. 1.5. Assignment of electrical safety group I is carried out at least once a year. 1.6. The immediate supervisor of a newly hired employee is obliged to organize training for assignment to group I. 1.7. If an employee has not completed Group I electrical safety training, he is suspended from independent work. (The employee is exempted only from independent work, and not from work in general.) 1.8. The list of positions and professions of employees requiring assignment to group I in electrical safety is approved by order of the enterprise. Such employees include personnel engaged in: - working with PCs, multimedia equipment and office equipment, etc.; — work in premises where there is electrical equipment; — cleaning of industrial premises of the enterprise. 1.9. Electrical installations pose a great danger to humans, and human senses cannot detect the presence of voltage on the equipment from a distance, since electric current is odorless, colorless and silent. 1.10. The inability of the human body to detect current before it begins to act leads to the fact that the worker does not realize the real danger and does not take protective measures in a timely manner. 1.11. The danger of electric shock is also characterized by the fact that the victim cannot provide assistance to himself, and if assistance is provided ineptly, the person providing assistance may also suffer. 1.12. Approximately half of accidents involving electric shock occur during the professional activities of the victims. According to some data, electrical injuries account for about 30% of the total number of all injuries at work and, as a rule, have serious consequences. In terms of the frequency of deaths, electrical injuries are 15-16 times higher than other types of injuries. 1.13. Non-electrical personnel must: - comply with internal labor regulations and the established work and rest schedule; - perform work included in the job responsibilities or assigned by the administration, provided that he is trained in the rules for the safe performance of this work; — apply safe work practices; - be able to provide first aid to victims. 1.14. An employee who violates or fails to comply with the requirements of this instruction is considered a violator of industrial discipline and may be subject to disciplinary liability, and depending on the consequences, to criminal liability; if the violation is associated with causing material damage, then the perpetrator may be held financially liable in the prescribed manner.

Frequency of certification

Any employee who begins official duties related to the operation of electrical equipment must undergo training in all safety categories. After he receives a certificate confirming the assignment of 1st group of electronic security, he can work without restrictions. However, at least once every 3 years, this employee must undergo new training.

This frequency is necessary to take into account changes in:

- power supply system and operating equipment;

- employee qualification level;

- technological production cycle;

- labor organization.

Thus, electrical safety certification is carried out periodically in accordance with the requirements of legal laws of different levels and departmental standards. Only training carried out according to a plan can be called periodic. Introductory, primary and unscheduled briefings are not of this type.

Types of briefings

Electrical safety training is required upon hiring. In addition, there are other types of similar events, which can be found in the table below.

Types of briefings provided

| Name | Summary |

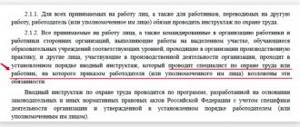

| Introductory | Conducted on the day of hiring. General safety issues are touched upon and occupational safety instructions are studied. A newly hired employee is introduced to the norms and rules approved at a particular enterprise |

| Primary | Conducted directly at the workplace, taking into account the responsibilities of the hired employee. The same type of briefing is provided for when transferring from unit to unit (from department to department), as well as for business travelers. A more in-depth study of the documents reviewed during induction training is underway. Employees more carefully study their production (job) instructions, as well as the rules for using electrical devices and equipment that they will encounter in the performance of their duties. |

| Repeated (or periodic) | For non-electrical personnel, the frequency of repeated training is 1 year |

| Unscheduled | Mandatory if there are changes in the current instructions on occupational safety and electrical safety, or if new technical documentation, rules and standards are introduced. Conduct unscheduled electrical safety training for non-electrical personnel in the following cases: • when replacing or upgrading office equipment; • if the employee violated the electrical safety instructions, and this could lead to injuries, fire, accident or electrical failure. instruments and equipment; • with a break in work for more than 2 months. This event can also be carried out at the request of supervisory authorities (as a rule, these are collective classes). |

Additional Information. Targeted training is applied to workers allowed into electrical installations, but does not apply to non-electrical personnel.

Carrying out repeated training

All types of briefings for the first group of electronic safety (except for the introductory one) are carried out by the heads of divisions (departments) or persons approved by order. When hiring, the occupational safety engineer (or the employee responsible for this function) provides instructions.

Procedure for assigning 1st electrical safety group

If we consider labor protection from different positions, it becomes clear that in any of the directions, it is important not only to work with personnel and ensure safe working conditions, but also to correctly and competently drawn up documents, because it is also necessary to protect the manager’s nerves and budget from fines, and this is always done with the help of a “piece of paper”

And it seems like such a simple procedure, but you need to prepare a lot of documents confirming the correct procedure for assigning group 1 in electrical safety, and simply making entries in a journal will not prove that the instructions were given in fact.

Electrical safety program 1 group

Any training and instruction in labor protection is carried out according to a specially prepared program, and in this area. You will need a group 1 electrical safety program.

There are no specific regulations for the design of the program for assigning group 1 in electrical safety; the main thing is to convey to workers the following topics while studying the basics of electrical safety:

- the effect of electric current on the human body;

- creating safe working conditions;

- personal electrical safety;

- rules for using electrical devices;

- step voltage;

- freeing the victim from exposure to electricity. current;

- providing first aid in case of electric shock.

The instruction time is also not specified, everything is in your hands, but the point is that you need not to miss anything and convey as much information as possible to the employee so that he is protected from the effects of electric current:

- when moving around the organization’s territory and premises;

- when connecting equipment to the network (you need to make sure that it is working properly);

- at the end of the working day (it is necessary to turn off electrical equipment);

- knew where to go in case of detection of equipment malfunctions.

You can download the program for assigning group 1 in electrical safety by clicking on the link.

And, of course, the program itself for conducting electrical safety training for 1 group is, in fact, a table indicating the main topics, and in order not to come up with a text every time, you should prepare instructions.

Electrical safety instructions group 1

The text part is very important, because an employee may forget the basics of electrical safety and first aid rules for a year, and having this document always “at hand” at the workplace, there is an opportunity to refresh his knowledge.

Electrical safety instructions for non-electrical personnel assigned to Group I must contain detailed information specified in the program.

This document is developed by the person responsible for electrical facilities, agreed upon with the labor protection service, if there is a trade union, then with its representative, and approved by the head of the organization.

If you need electrical safety instructions group 1 as an example, it is located at this link.

The electrical safety instructions for personnel assigned to group 1 are quite lengthy, so it will not be possible to quickly release workers, especially after the instruction they need to test their knowledge.

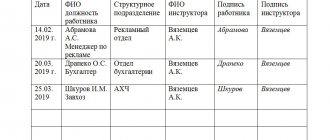

Logbook for assignment of group 1 for electrical safety to non-electrical personnel

If the employee has answered all the questions asked, you will need to log the assignment of group 1 for electrical safety to non-electrical personnel in which you need to register.

Moreover, in this case it is not necessary (clause 1.4.4. Order of the Ministry of Energy No. 6).

The logbook for assigning group 1 for electrical safety to non-electrical personnel in a specific form is not regulated by law, but it must contain the following information:

- FULL NAME. employee;

- job title;

- date of the ES briefing;

- signatures of the inspector and the instructed.

In order not to look for the journal form for assigning 1st electrical safety group, I leave you a download link.

The signatures of both parties must be mandatory, otherwise it will be considered that the legal requirement has not been met and the employee does not have an electrical safety group.

Employer's liability

After employment, it is mandatory to conduct electrical safety training and assign a group, and if this requirement is not met, then administrative liability under Art. 9.11 Code of Administrative Offences:

- for an official and individual entrepreneur from 2000 to 4000 rubles;

- for a legal entity – from 20,000 to 40,000 rubles or suspension of activities for up to 90 days.

The fine is not as great as if you fail to comply with labor protection or environmental safety requirements, but nevertheless it should not be tolerated.

Although non-electrical personnel with electrical safety group 1 do not often encounter the danger of electric shock and the work is not as dangerous as that of others, they still need to be concerned about their well-being, because in case of heart problems, a fatal accident can occur and then the question of the emergence of criminal liability will already arise (Article 143 of the Criminal Code of the Russian Federation).

Useful video

An example of tickets for passing the Group 2 electrical safety exam and answers to questions can be found in this video:

conclusions

Working with electrical devices requires a certain level of training. If an employee does not have the required level of clearance, then his management may fall under administrative, and in the event of an emergency, criminal liability.

Therefore, when applying for a job or being promoted, an employee must be instructed in a special program, then take an exam and be assigned the appropriate qualification with the issuance of a certificate.

Only after this the employee has the right to work with certain electrical machines and installations.

n1.doc

7

- determine the class of a machine or tool from the passport;

- check the completeness and reliability of fastening of parts;

- verify by external inspection that the cable (cord), its protective tube and plug are in good condition, the integrity of the insulating parts of the housing, the handle and brush holder covers, and protective covers;

- check the operation of the switch;

- perform (if necessary) RCD testing;

- check the operation of the power tool or machine at idle speed;

- Check the serviceability of the grounding circuit on a class I machine.

It is not allowed to use hand-held electric machines, portable lamps and power tools, with related auxiliary equipment that have defects. When using power tools, hand-held electric machines, portable lamps, their wires and cables must be suspended whenever possible. The cable of the power tool must be protected from accidental mechanical damage and contact with hot, damp and oily surfaces. If any malfunctions are detected, work with hand-held electrical machines, portable power tools and lamps must be stopped immediately. To maintain good condition, carry out periodic tests and inspections of hand-held electrical machines, portable power tools and lamps, auxiliary equipment, by order of the head of the organization, a responsible employee with group III must be appointed. These portable electrical receivers must be subject to periodic inspections and tests within the time limits established by GOST 12.2.013-91, the technical specifications for them and the Rules for the operation of consumer electrical installations. Periodic inspections are not carried out less than once every 6 months and includes:

- visual inspection;

- check the idle speed for at least 5 minutes. At the same time, the clear operation of the switch is checked;

- measuring insulation resistance with a 500 V megohmmeter in the on state. The insulation resistance value must be at least 0.5 MOhm, and for class II machines - at least 2 MOhm;

- checking the integrity of the grounding circuit. To do this, use a device with a voltage of no more than 12 V, one of which is connected to the grounding contact of the connector (plug), and the other to a metal part of the product that is accessible to touch. The circuit is considered operational if the device shows the presence of current.

We recommend studying Toki Fuko

____________ _____________

7

Lectures Laboratory References Essays Questions Standards

Portable electrical receivers

Electrical receivers that are not permanently installed are called portable. Connection to such electrical devices is made with flexible cords or cables. These include hand-held power tools, electric ovens, compressors, vacuum cleaners, kettles, electric saws, refrigerators, etc.

The devices are powered from a 220/380V power supply or through step-down transformers.

The transformer windings should not have electrical connections; double insulation should be installed on these elements of equipment.

Metal elements of electrical devices with a voltage of 50V or more alternating current and more than 120V direct current are subject to grounding (except for devices with double insulation), provided they are operated in particularly hazardous production workshops.

Grounding is performed by connecting to the plug-in contacts:

- fourth core for three-phase networks;

- the third for single-phase.

The cross-section is usually equal to the phase wires. The use of neutral as a grounding conductor is prohibited.

The connection to the plug-in contacts occurs before electricity is supplied to the installation.

The grounding conductor has a different marking from other conductors. The order of disconnecting the contacts should be reversed.

The equipment must ensure insulation of the grounding contact from the phase wires.

Class 1 power tools must be used exclusively with the use of protective equipment, provided that work is carried out in hazardous areas and workshops without increased danger. Use in particularly hazardous areas is prohibited. In such premises, it is allowed to use hand-held power tools with protection classes 2 and 3. Before use, you must ensure that the device is operational, complete, and insulated.

Safety precautions:

- portable electrical receivers, according to GOSTs, must undergo regular inspection;

- if during inspection any malfunctions, damage to the casing or sheath of the wire are found, such tools are removed from use;

- wires and cables must be protected from contact with heating devices, caustic substances, as well as from mechanical damage.

Checking devices:

- carried out at least once every 6 months;

- includes external inspection, electrical tests of all modes of use;

- All devices that are grounded are tested for the integrity of the grounding conductor.

Requirements that a candidate must meet to receive 1 group admission:

- professional, higher (electrical) technical education – not required;

- No work experience required.

What an employee should know upon completion of the training and orientation program:

- basic concepts about electrical networks and electrical equipment;

- the main causes of electrical injuries, sources of danger of electric shock;

- rules for using simple electronic devices;

- first aid skills.

Possible consequences of non-compliance

Electrical safety is an integral part of occupational safety. Failure to comply with its requirements can be of 2 types: violation of established rules for handling equipment and lack of personnel training. This can also include improperly executed TB documents.

If accidents occur at work, the following are responsible for the consequences:

- the head of the institution - as the person responsible for everything that happens in this organization;

- employee responsible for TB (and ES);

- an employee who committed violations that led to an accident.

Incidents that resulted in human death, moral and material damage, environmental pollution, etc. are subject to investigation. Depending on the situation, it is carried out by labor safety inspectors, representatives of departments and supervisory authorities. If the investigation reveals an offense (crime), the materials are sent to court.

Persons responsible for an accident may be punished:

- disciplinary;

- administrative;

- material;

- criminal.

If an accident occurs to a person who handled electrical equipment without at least 1 group, then all managers who supervise the activities of this employee will be held accountable. Punishment will also follow for the employee responsible for instruction in electronic safety.

However, personnel are subject to administrative or disciplinary liability even in the absence of emergency incidents. This may occur as a result of violations identified during scheduled and unscheduled inspections conducted by departmental or supervisory authorities. Violations may include:

- failure to comply with briefing deadlines;

- incorrect design of the journal or its absence;

- carrying out work with electrical appliances by a person who does not have a clearance group.

Depending on the characteristics of the institution, punishment may apply to the head of the enterprise, heads of departments and the person responsible for TB.

Logbook for assignment of group I for electrical safety to non-electrical personnel - Bitrade

The logbook for assignment of group 1 for electrical supply is filled out in all enterprises with registered electrical equipment in accordance with POT R M-016-2001 “Interindustry rules for labor protection (safety rules) during the operation of electrical installations.”

The magazine allows you to ensure safe maintenance of electrical installations by both technical specialists and non-electrical personnel.

This category includes all heads and deputies of departments, workshops and sections, heads of individual energy services and companies as a whole.

What does electrical safety group I mean?

This group includes non-electrical employees who perform their duties in conditions where there is a high probability of receiving electric shocks. They are not directly employed on electrical installations, but directly or indirectly use them in the course of performing their job duties.

This can be both production and non-production personnel, including premises cleaners, dispatchers, etc. The full list of positions that fall into this group is approved by the director of the enterprise. It is the fact of obtaining the first electrical safety group that is noted in the standardized journal.

Group I is the lowest available, the highest is V (fifth). This group is received by employees of the enterprise without special electrical engineering training.

How to get Group I in electrical safety

Persons who have the following knowledge are allowed to receive instructions for obtaining the first group:

- Why is electric current dangerous?

- safety rules for contact with electrical appliances;

- providing emergency assistance in case of electric shock.

If necessary, not only an oral interview is carried out, but also a test of practical skills in trouble-free work with electrical installations and an assessment of emergency assistance techniques in case of electrical damage. Classes are taught by a responsible employee with group III or higher.

Procedure for filling out the journal

The journal for assigning group 1 for electrical safety is filled out in accordance with the established form. Before making the first entry, the responsible person fills out the first sheet and puts a certification on it. The title page indicates the full name of the organization, its structural unit (optional) and two dates.

Inside the journal, in special columns, the serial number of the entry, the full name of the person who passed the certification, his position, the date of assignment of the group (plus the date of the previous assignment, if any) are indicated, as well as two signatures - the certified person and the inspector.

The general logging sequence is as follows:

- The head of the enterprise by order appoints a person responsible for electrical safety. He also lists the positions that should be assigned to group 1;

- employees undergo training, following which they sign in a log and receive group 1;

- employees listen to repeated lectures and undergo an oral knowledge test once every 12 months.

The pages of the magazine are numbered and laced. The last of them bears the signature of the person responsible for the electrical equipment of the enterprise or its separate structural unit (for example, a branch). The ends of the lacing are fastened with paper on which the company's seal is affixed.

Other logging requirements:

- Empty lines are not allowed;

- corrections are not allowed (incorrect text is carefully crossed out, the correct version is indicated next to it);

- The journal maintenance is controlled by the chief power engineer of the enterprise;

- It is desirable, but not necessary, to seal each page of the magazine;

- The document must be kept for 10 years.

How to profitably order an accounting journal in

We offer only standardized documentation that complies with GOSTs and the current regulatory framework.

From us you can purchase not only magazines, but also forms, stands, safety signs, technical literature and much more at a good price.

We also offer other ways to place an order: you can write in the online chat or select the contact number at the top and call our manager.

We advise you to study Copper resistance depending on temperature

Any batch of magazines can be promptly picked up from our warehouse or received by delivery service in Moscow, Moscow Region or to another city in the Russian Federation.

Global educational program for assigning the 1st electrical safety group to non-electrical personnel!

Greetings, friends! This note contains comprehensive information for thinking about who should assign 1 electrical safety group to non-electrical personnel, how this should happen according to all safety standards (the author’s opinion) and what documents need to be drawn up for the legitimate assignment of 1 electrical safety group (the author’s proposal) .

The material on electrical safety is really interesting, deep and high quality! For note, it was kindly provided by our colleague, occupational safety specialist, Vladimir Yakovlevich Shumik (author of the material). Thank you, Vladimir! The original title of the article is “And once again about the assignment of the 1st electrical safety group to non-electrical personnel.” The safety of workers in enterprises, institutions, offices (hereinafter referred to as enterprises) is given great importance. The legislator requires training, instructions, and knowledge testing of workers on labor protection, fire safety, and electrical safety. In matters of electrical safety, the legislator requires not only training and instruction for workers, but also the assignment of appropriate electrical safety groups to them. Unfortunately, today, many questions have arisen regarding the training and assignment of group 1 in electrical safety to non-electrical personnel. And this is largely due to the imperfection of the published regulatory legal acts in this area. Regulatory legal acts that formulate the requirements for electrical safety and the provision of training, instruction, testing of knowledge on labor protection, assignment of electrical safety groups are:

- Rules for the technical operation of consumer electrical installations, approved by order

- Ministry of Energy of Russia dated January 13, 2003 No. 6 (hereinafter referred to as NPA (1)).

- “Rules on labor protection during the operation of electrical installations”, approved by order of the Ministry of Labor and Social Protection of the Russian Federation dated July 24, 2013 No. 328 n (hereinafter referred to as NLA (2)).

- “The procedure for training in labor protection and testing knowledge of labor protection requirements for employees of organizations”, approved by the Ministry of Labor and Social Development of the Russian Federation No. 1, Ministry of Education of the Russian Federation No. 29, resolution dated January 13, 2003, (hereinafter referred to as NPA (3)).

- GOST 12.0.004-90. Organization of occupational safety training (hereinafter referred to as NLA (4));

Let's consider clause 1.4.4. (first sentence) Legal acts (1). It states that “Non-electrical personnel performing work that may pose a risk of electric shock are assigned Electrical Safety Group 1.” If by work in the above sentence we mean the employee’s workplace and the performance of his functional duties by profession, then it should be noted that the employee can be electrically injured outside his workplace and without performing his professional duties. For example: 1. when an employee is in an area where electrical receivers are operated by other employees; 2. when operating electrical installation fittings (electrical switches, electrical sockets), electrical wiring, electrical machines, input and distribution devices, lighting and distribution panels, electrical extension cords that are not at the employee’s workplace, but which may have to be used in emergency situations; 3. when operating electrical receivers that are not involved in the employee’s work: 3.1. when operating electrical receivers used during a break from work for rest, eating, heating for cooking, heating food, heating workers (electric kettle, electric boiler, electric stove, microwave oven, electric heater, electric refrigerator, electric extension cord, etc.); 3.2. during the operation of electrical receivers used by the enterprise during public and cultural events on the territory of the enterprise and beyond (electrical amplification equipment, electric spotlights, electric illumination, televisions, projection systems, tape recorders, electrical extension cords, etc.); 4. when entering an area where there is a broken wire of overhead power lines, an electric cable of underground power lines protruding from the ground, temporary electrical wiring is used; 5. when you are on the territory, in buildings, structures of the enterprise during a thunderstorm, when ball lightning appears; 6. when the employee is in an area where the employee is exposed to static electricity or an electromagnetic field; 7. when rescuing other employees of the enterprise who have been exposed to electric current in the premises and on the territory of the enterprise; 8. when extinguishing electrical installation fittings, electrical wiring, input distribution devices, lighting and distribution panels, electrical extension cords, electrical receivers, electrical equipment, power tools, electric lamps that are energized in the premises and on the territory of the enterprise. Based on the above, the author of this article suggests that all employees of the enterprise, from the director to the janitor of the enterprise, undergo electrical safety training, because each of them may find themselves in the situations described above. In addition, when completing this training, there is no need to assign employees to any electrical safety group. After all, when employees undergo training on labor protection and fire safety, no groups are assigned. Electrical safety groups must be assigned only to employees of the electrical and electrical engineering personnel of the enterprise. Let's consider clause 1.4.4. (third sentence) Legal acts (1). It states that “Personnel who have mastered the electrical safety requirements related to their production activities are assigned group 1 with registration in a journal in the prescribed form...” Let’s analyze this proposal in parts. 1. “Personnel who have mastered the electrical safety requirements ....” Question: how to check and make sure that the personnel have mastered the electrical safety requirements or not? In what regulatory legal act or local regulatory legal act should these electrical safety requirements be formulated? 2. “...to its production activities...”. Since group 1 for electrical safety is assigned not only to workers engaged in production activities, but also to workers engaged in non-production activities (for example, office workers), it is proposed to use the phrase “professional activity” instead of the phrase “production activity”; 3. “...assigned to group 1 with registration in the journal in the established form...” Question: by whom in the established form? Why is the full name of this journal, its form, the order of production, filling, maintenance, and storage not indicated? 4. Why, in this sentence we are talking about mastering what electrical safety requirements, and in the next sentence we are talking about conducting instructions and testing knowledge? Maybe it's the other way around? Let's consider clause 1.4.4. (fourth sentence) Legal acts (1). It states that “Assignment to Group 1 is made through instruction, which, as a rule, should be completed by a knowledge test in the form of an oral examination and (if necessary) a test of acquired skills in safe working methods or providing first aid in case of electric shock.” Let's look at this proposal piece by piece. 1. “Assignment to group 1 is made through instruction,...”. a) This part of the sentence is stylistically constructed illiterately. In the opinion of the author of this article, this part of the proposal can be more correctly formulated as follows: “Group 1 for electrical safety is assigned to non-electrical personnel after briefing them ...” b) What kind of training? According to NLA (3) and NLA (4), there are: introductory briefing on labor protection, initial briefing on labor protection at the workplace, repeated briefing on labor protection, targeted briefing on labor protection, unscheduled briefing on labor protection. There are similar instructions on fire safety. If the legislator introduces a new type of instruction—instruction on electrical safety—then it should be written that way. In addition, it is necessary to indicate the time characteristics of the briefing (introductory, initial at the workplace, repeated, targeted, unscheduled), because the regulatory legal acts (1) state that “Assignment of 1 group in electrical safety is carried out at least once a year” , and in the event of an accident involving an employee receiving an electrical injury, it is probably necessary to conduct unscheduled electrical safety training or not? In addition, if such an event is mentioned as briefing, then it is clearly necessary to provide a standard program for such briefing, standard local regulatory legal acts (instructions) that should be included in the briefing program. And so there is no full name of this instruction, nor how it is compiled, nor the number of sections of which it should consist. In addition, it is not indicated that there should be one electrical safety instruction at the enterprise or for each structural unit of the enterprise in order to stipulate in it the electrical safety requirements specific to each structural unit of the enterprise. 2. “...instruction, which, as a rule, should end with a knowledge test in the form of an oral questioning and (if necessary) a test of acquired skills in safe ways of working or providing first aid in case of electric shock. a) That is, after the briefing, you can conduct a knowledge test, or you can not conduct it. I read the instructions on electrical safety and “goodbye” to the workers. And acquired skills in safe ways of working or providing first aid in case of electric shock can also be tested, or they may not be tested. Why bother yourself? If this is so, then why didn’t the legislator provide at least an approximate list of situations in which testing the knowledge and acquired skills of employees is mandatory or optional. This paragraph contradicts paragraph 7.2.5. NLA (4), which is higher in status than any Rules, which states more specifically: “Workers are allowed to work independently after... testing theoretical knowledge and acquired skills in safe ways of working.” b) Question: what is an oral survey? How to carry it out? To what extent should it be carried out? Should we interview everyone? What if 20-30 employees undergo training? c) Question: what is a test of acquired skills? How to carry it out? To what extent should it be carried out? Does everyone have to show acquired skills? What if 20-30 employees undergo training? Let's consider clause 1.4.4. (fifth sentence) Legal acts (1). It states that “The assignment of electrical safety group 1 is carried out by an employee from among the electrical personnel of a given Consumer with an electrical safety group of at least 3.” 1. Question: why train managers, their deputies, heads of structural divisions and specialists on electrical safety issues in the process of training and testing knowledge on security issues, if after that they, it turns out, are not able to provide instructions on basic electrical safety measures for their subordinate workers (with the exception of workers belonging to electrical and electrical engineering personnel). After all, non-electrical personnel are required to know the most basic things:

- electrical hazard;

- electrical safety requirements for the operation of office and household electrical receivers;

- electrical safety requirements for the operation of technological electrical equipment (external inspection, switching on, monitoring operation, switching off) (during its operation);

- the procedure for releasing an employee exposed to electric current;

- procedure for providing first aid to a victim of electric current.

That's all. Is it really possible that in order to train your subordinate workers in this and assign them 1st electrical safety group, do you need to be an electrical technician and have as many as 3rd electrical safety group? 2. Question: Does a person in electrical engineering personnel who has an electrical safety group of at least 3 have the right to assign electrical safety group 1 or not? Let's consider the first sentence of clause 2 of the Notes to Appendix No. 1 of the Regulations (2). It states that “Group 1 Electrical Safety applies to non-electrical personnel.” According to the name of the application, electrical safety groups are assigned, not distributed (only the plague is distributed). Are non-electrical personnel assigned electrical safety group 1 or not? Unclear. Let's consider the second sentence of clause 2 of the Notes to Appendix No. 1 of the Regulations (2). It states that “The list of positions and jobs requiring classification of production personnel into group 1 is determined by the head of the organization (separate division).” I believe that this proposal is poorly drafted because:

Want to know what safety legislation changes have occurred in 2021? Come to our online conference! Participation is free.

- electrical safety groups are assigned not to workplaces, but to workers of certain professions;

- Group 1 for electrical safety is assigned not only to production personnel, but also to non-production personnel (office workers and others).

3. if the head of the organization single-handedly determines the List of positions, jobs that require classification of production personnel into group 1, then “why the hell” does the enterprise have a person responsible for electrical equipment and a labor protection specialist on staff? The above proposal is proposed to be formulated as follows : The list of professions and positions of workers who need to be assigned group 1 in electrical safety is developed by the person responsible for electrical equipment at the enterprise (organization), agreed with the occupational safety specialist and approved by the head of the enterprise (organization). Consider the second sentence of paragraph 2 Notes to Appendix N 1 NLA (2). It states that “Personnel who have mastered the electrical safety requirements related to their production activities are assigned group 1 with registration in a journal, which must contain the last name, first name, patronymic of the employee, his position, the date of assignment of group 1 on electrical safety, signature of the person being checked and the inspector. I think that this proposal is also poorly drafted because:

- again the full name of the journal is not indicated;

- “...in a journal that must contain the name,...”. I think that this phrase is formulated stylistically incorrectly. I suggest: “...in a journal in which the last name must be indicated...”;

- the list does not indicate “profession”, which means that workers in blue-collar professions are not assigned Group I for electrical safety, which is incorrect;

- instead of “signature of the person being inspected”, “the signature of the employee who is assigned the electrical safety group” is suggested, and instead of “the signature of the inspector” - “the signature of the official who has assigned the electrical safety group.” Employees of the electrical safety group are assigned, not checked.

Having studied the regulations (1) and regulations (2), the author of this article did not find information that said what should be done with an employee who suffered from an electric current through his fault and remained alive? What needs to be done with other employees of this structural unit or enterprise? If it is necessary to conduct an unscheduled briefing on electrical safety with them, then this must be written to the regulatory legal acts. The above legal acts also do not indicate:

- definition of the term “non-electrical personnel”. The author of this article considers the definition of the term “non-electrical technical personnel” given in the regulatory legal acts (1) to be incorrect (personnel who do not fall under the definition of “electrical technical”, “electrotechnological”)

- the age at which non-electrical personnel can be assigned electrical safety group 1;

- the period (before the start of work or within one month from the date of hiring) for conducting initial training, testing knowledge and assigning 1 group in electrical safety;

- requirements for the health status of an employee of non-electrical personnel with 1 electrical safety group;

- qualification requirements for non-electrical personnel with group 1 electrical safety (what they should know and be able to do);

- characteristics of group 1 on electrical safety for non-electrical personnel (what types of work they are allowed to perform and which are prohibited);

- measures of responsibility of employees of non-electrical personnel of the 1st group on electrical safety for violations of electrical safety requirements.

Since the legislator has not developed standard local regulations (Procedures, Programs, Instructions) for organizing training, testing knowledge and assigning group 1 in electrical safety to non-electrical personnel, specialists and managers of structural divisions of enterprises have to develop them independently and, unfortunately, not always competently. Thus, over the past decade, the author of this article has come across versions of the same Labor Safety Instructions for non-electrical personnel, who are assigned group 1 in electrical safety, in periodicals on labor protection, in books, and on the Internet. Already in the title of this instruction there is an error, since labor protection instructions are developed according to professions and types of work performed. Although, along with labor safety instructions, there are also instructions such as fire safety instructions. Therefore, by analogy, instructions that reflect electrical safety issues should be called Electrical Safety Instructions. The above instructions, as a rule, on 1.5-2 sheets, superficially outline: the requirements for conducting instructions, and theoretical material about the dangers of electric current and the consequences of its impact on the human body, and the electrical safety requirements for the operation of electrical receivers, and the provision of first aid to victims of electric current. All this, nothing less than, cannot be called a “hodgepodge”: about everything - but in a little bit. Moreover, material devoted to the consequences of the effects of electric current on the human body and the provision of medical care in some instructions takes up more than 90% of the volume of the entire instruction, and material devoted to the electrical safety requirements themselves takes up less than 10%. The author of this article proposes, in this case, to “separate the flies from the cutlets” and develop the following independent local regulatory legal acts on the issues of conducting briefings, testing knowledge and assigning Group 1 in electrical safety to non-electrical personnel:

- The procedure for conducting instructions, testing knowledge and assigning group 1 in electrical safety to non-electrical personnel of the enterprise.

- A program for conducting briefing, testing knowledge and assigning 1 electrical safety group to non-electrical personnel for each structural unit of the enterprise.

- Electrical safety instructions for non-electrical personnel, who are assigned 1 electrical safety group for each structural unit of the enterprise.

- Lecture material on the dangers of electric current and the consequences of exposure to electric current on the human body.

- Instructions for providing pre-medical self- and mutual assistance to victims of electric current.

+ DOWNLOAD A SET OF DOCUMENTS FOR ASSIGNMENT OF 1 GROUP ON ELECTRICAL SAFETY As an example for the development of the above documents, the following options are offered below. Examples of the development of instructions on the use of primary fire extinguishing agents and on providing pre-medical self- and mutual assistance to victims of electric current are not given, since no problems arise in their preparation. In addition, the “Safety Rules for the Operation of Consumer Electrical Installations” in Appendix B10 very competently sets out material on providing first aid to victims of electric current. PS According to the author of this article, it would be reasonable for the legislator to: 1. develop: 1.1. Standard procedure for conducting instructions, testing knowledge and assigning Group 1 electrical safety to non-electrical personnel. 1.2. A standard program for conducting instructions, testing knowledge and assigning Group 1 electrical safety to non-electrical personnel. 1.3. Typical lecture material on the dangers of electric current and the consequences of exposure to electric current on the human body. 1.4. Standard instructions on electrical safety for non-electrical personnel assigned to electrical safety group 1. 1.5. Standard instructions for providing pre-medical self- and mutual assistance to victims of electric current. 2. obligated the heads of the structural divisions of the enterprise (regardless of whether they are electrical personnel or not) to undergo training and testing of knowledge on electrical safety in the commission of their enterprise, a higher organization or a territorial body of the state energy authority with the subsequent assignment of 2 (1) electrical safety groups (and maybe even without specifying the electrical safety group, because heads of structural units undergo a knowledge test on occupational safety issues and do not assign them any groups); 3. obligated the heads of enterprises, institutions, offices to organize, on the basis of the Standard Instructions on Electrical Safety for employees of non-electrical personnel, who are assigned 1 electrical safety group, the development of Electrical Safety Instructions for employees of non-electrical personnel, who are assigned 1 group for electrical safety for each structural unit of the enterprise; 4. obligated the heads of structural divisions of enterprises, institutions, offices to individually conduct instructions, test knowledge of electrical safety among employees subordinate to him (with the exception of electrical and electrical engineering personnel, engineering and technical workers) and assign them 1 group in electrical safety at least once a year or without assigning an electrical safety group. After all, employees undergo training on labor protection and fire safety and are not assigned any groups. The questions included in the training program for assigning group 1 in electrical safety are the most basic, and if the head of a structural unit cannot train his subordinate workers in the basics of electrical safety, then such a manager cannot organize the work of employees; 5. obligated all employees of any enterprise, institution, office (with the exception of employees of electrical and electrical engineering personnel, engineering and technical workers) to undergo training and knowledge testing for assignment to group 1 in electrical safety (or without assigning a group); 6. obligated to assign electrical safety groups only to employees of electrical and electrical engineering personnel, engineering and technical workers, heads of structural divisions of an enterprise, institution, office (if necessary). Only if the above-mentioned regulatory legal acts are in place would it be possible to talk more seriously about high-quality training for employees of enterprises, institutions and offices on electrical safety issues. You can express your thoughts on the issues raised in this article here by commenting.

In what cases is it carried out?

This training is carried out in several cases:

- The employee was promoted and now his new duties involve working with electrical appliances and electricity.

- An accident was recorded at work caused by a violation of electrical safety rules.

- An employee with a Group 2 clearance did not perform his duties for more than 30 calendar days (was on sick leave, on vacation, on a business trip).

- There was a break in production.

Having Group 2 in electrical safety requires passing an exam and receiving a certificate.

Accordingly, the level of responsibility when performing one’s duties is different.

What documents should there be?

To conduct training with assignment to Group I, you must complete a number of mandatory documents:

- List of professions and types of work that require assignment to group I in electrical safety. This list is approved by a local document, as a rule, this is an order (instruction) for the enterprise.

- A training program for assigning electrical safety group I, which should contain general information on electrical safety, information about the effects of electric current on the body and recommendations for first aid in case of electric shock.

- Logbook for training on assignment of group I in electrical safety to non-electrical personnel.

Who is assigned 1st EB group

Personnel who do not service electrical installations, but in their work have a risk of receiving any degree of electric shock, are classified as non-electrical workers. These include:

- administrative workers not involved in maintenance, repair and installation of electrical equipment;

- office employees who use electrical appliances (lamps, kettles, microwave ovens) and equipment (computers, printers, scanners, faxes) in their work process.

Non-electrical personnel

These categories are assigned 1 electrical safety group based on the instructions provided and subsequent knowledge testing, which is a survey on the topics covered.

Who needs electrical safety training?

For ease of understanding, we will divide all personnel into “categories”:

- electrical (electrical) personnel (workers dealing with electrical equipment, electrical installations or power tools). This category of workers is assigned electrical safety group II-V (with the issuance of certificates);

- non-electrical personnel (workers who are not directly related to the repair and installation of electrical equipment, but use electrical devices to perform their duties (PC, printer, fax, other electrical devices) and perform work that may pose a risk of electric shock). This category of workers is assigned electrical safety group I (without issuing certificates).

The concept of induction training on electrical safety does not exist. Electrical safety training is carried out only for assignment to group I.

And to assign an employee a higher group, i.e. II – V gr., here you won’t get by with simple instructions. To do this, the employee must undergo a special training course at the training center in accordance with the training programs. Training programs differ in content for different qualification groups. After testing knowledge and passing exams, the employee is issued a certificate for the appropriate access group.

Based on the above, electrical safety training is carried out for all employees of the organization, except electrical personnel.

And the concept of “instruction” is applicable only for workers with electrical safety group I.

ELECTRICAL SAFETY REQUIREMENTS DURING OPERATION

Make sure that electrical plugs, electrical sockets and switch covers are intact.

Check the presence of primary fire extinguishing equipment and personal respiratory protection equipment in the room in case of smoke.

Do not connect electrical appliances to the electrical network with wet (damp) hands.

Follow the rules for operating electrical appliances, do not expose electrical appliances and equipment to mechanical shocks, and do not allow them to fall.

Do not touch exposed (damaged) wires and other live parts that are energized.

It is not allowed to use electrical appliances if they are malfunctioning, sparking, insulation failure, etc.

Cables and wires of electrical appliances must be protected from accidental mechanical damage and contact with hot, damp, oily surfaces.

Do not carry out repairs or adjustments to faulty electrical appliances yourself.

Measures to ensure electrical safety at work

Ensuring electrical safety in production can be achieved by a whole range of organizational and technical measures: appointing responsible persons, carrying out work according to work orders and orders, carrying out scheduled repairs and inspections of electrical equipment on time, personnel training, etc.

Let's look at some measures to prevent electrical injuries.

Grounding (grounding) of electrical equipment housings.

Under normal operating conditions, no current flows through grounded connections. During a fault condition on a circuit, the magnitude of the electrical current (through low resistance grounded connections) is high enough to melt fuses or trigger protection that removes power from the electrical equipment.

- Application of manual electric machines of class II or III.

- Use of lamps with reduced voltage.

In rooms with increased danger and especially dangerous ones, portable electric lamps must have a voltage no higher than 50 V. When working in particularly unfavorable conditions (switch wells, boiler drums, etc.), portable lamps must have a voltage no higher than 12 V.

- Connecting and disconnecting auxiliary equipment (transformers, frequency converters, residual current devices, etc.) to the electrical network must be performed by electrical personnel with group III operating this network.

- Use of residual current devices (RCDs).

This device responds to deterioration of the insulation of electrical wires: when the leakage current rises to a limit value of 30 mA, the electrical wires are disconnected within 30 microseconds. RCD is used to protect indoor electrical wires, for the safety of working with hand-held electrical machines and when carrying out electric welding work in high-risk and especially dangerous areas.

Use of protective equipment (dielectric gloves, carpets, boots and galoshes, stands, insulating tools, etc.).

GENERAL ELECTRICAL SAFETY REQUIREMENTS

When using any electrical appliances or devices, you must always remember that incorrect handling, faulty condition of the electrical wiring or the electrical appliance itself, or failure to comply with certain precautions can lead to electric shock. Faulty electrical wiring can cause wires to ignite and cause fires.

Persons authorized to operate electrical appliances must comply with the internal labor regulations of the organization and the work and rest regimes established in the organization.

Non-electrical personnel of the organization must be familiar with the rules for providing first aid to victims of electric current.

Tags

5АЗМВ DIALux Ex PLC Certification Dielectric boots Explosion safety Galoshes Double-sided switch Grounding Insulated tool Instruction Testing Cable Insulating pliers Rubber carpets Contactor Ladders Operational negotiations Operational log Lighting control gear Dielectric gloves Testing knowledge on electrical safety Loading TRN Inspection of contacts Repair PME SIZ STDP Thermal relay TRN RCD Index Voltage Photo AD 5000 kW Insulating rod Electrical safety Electric motor Electrical clamps Energy saving types of repairs PPR schedule two-way lighting control cable coupling TRN adjustment commissioning transformers

Latest documents in the Database:

Occupational Safety and Health

Labor protection instructions for instrumentation mechanics

Job Description for the Head of the Electrical Engineering Laboratory

Job description of a mining foreman

Act on violation of labor discipline

Fire safety

Order on approval of fire regulations

Sample fire safety regime at an enterprise

Order on the creation of an object unit of the RSChS

Instructions for fire safety on a construction site

electrical safety

Instructions for the person responsible for electrical equipment

Regulations on the department of the chief power engineer

Order appointing someone responsible for power tools

Order on persons responsible for issuing work permits and orders in electrical installations

EFFECT OF ELECTRIC CURRENT ON HUMAN

If an electric current flows through the human body, it can cause a variety of effects on various organs, including the central nervous system.

The human body is a conductor of electric current. However, the conductivity of living tissue, unlike the conductivity of conventional conductors, is determined not only by physical properties, but also by complex biochemical and biophysical processes inherent in living matter. As a result, the resistance of the human body is a variable value that has a nonlinear dependence on many factors, including the condition of the skin, physiological processes occurring in the body, parameters of the electrical circuit, and the state of the environment.

Passing through the human body, electric current can produce thermal, electrolytic, mechanical, and biological effects:

- the thermal effect of the current manifests itself in burns of certain parts of the body, heating to high temperatures of blood vessels, blood, nervous tissue, heart, brain and other organs located in the path of the current, which causes serious functional disorders in them;

the electrolytic effect of the current is expressed in the decomposition of organic liquids, including blood, which is accompanied by significant disturbances in their physicochemical composition;

the mechanical (dynamic) effect of current is manifested in the appearance of pressure in the blood vessels and tissues of the body when blood and other fluids are heated, as well as displacement and mechanical tension of tissues as a result of involuntary muscle contraction and the influence of electrodynamic forces;

the biological effect of current is manifested in irritation and excitation of living tissues of the body, as well as in disruption of internal bioelectric processes occurring in a normally functioning organism;

The result of exposure to electric current on a person is injury.

Effect on the body

Electrical safety program for personnel of qualification group 2

It manifests itself in 5 directions, none of which can be the only one:

- Thermal effects manifest themselves in heating of living tissues and the presence of burns (from mild irritation to complete charring). Overheating of internal organs causes disruption (full or partial) of their functionality.

Types of Electric Shock Injuries

- Mechanical impact . It is expressed in violation of the integrity of living tissues. Occurs due to chaotic muscle contraction. Muscle ruptures and bone fractures are common in electrical injuries.

- Electrolytic . Causes changes in the physical and chemical composition of body secretions - plasma, saliva, bile, gastric juice, etc.

- Biological – irritation of cells that lead to continuous muscle contraction: disruption of the normal functioning of the body. In this case, fainting, paralysis of the respiratory organs and heart are observed.

- Reflex impact . Expressed in damage to the nervous system: speech disorders, etc.

ELECTRICAL SAFETY RULES

- electric shock when touching live parts;

faulty insulation or grounding;

sparking;

fire.

- Before using electrical appliances for the first time, carefully read the operating instructions for this electrical appliance;

Switch on electrical appliances by inserting a working plug into a working socket;

If an electrical appliance malfunctions, stop working, disconnect the electrical appliance from the network and inform your immediate supervisor;

strictly comply with the requirements of posters and safety signs in buildings, premises and on the territory;

do not step on electrical wires and temporary wiring cables laid on the floor (ground);

persons operating electrical appliances are required to strictly observe fire safety rules, know the location of primary fire extinguishing equipment, as well as the places for their emergency shutdown;

the victim or eyewitness of the accident must immediately report to his immediate supervisor about each accident;

During the operation of electrical appliances, personnel must keep the workplace clean.

PPE

- To ensure safety when performing work, PPE should be used. Insulating agents should be used at the voltage specified in the instructions.

Dielectric gloves for working in electrical installations

- Warning posters should be posted to mark the workplace.

- Electrical appliances should only be connected to working sockets using working plugs with wires.

- It is prohibited to operate electrical equipment by persons who do not have permission to do so.

Dielectric boots for protection against electric shock

- It is forbidden to step on wires and metal products lying on the ground.

- Equipment is turned off before starting work and during breaks.

- If defects (external or operational) are detected, the equipment should be removed from use.

Dielectric Hand Tool for High Voltage Protection

Who belongs to electrical and non-electrical personnel

ETP (electrical technical personnel) is a category of workers who operate electrical installations and carry out commissioning, installation work, maintenance and repair of electrical equipment.

This category includes:

- management of electrical installations - administrative and technical personnel.

- direct performers - operational, maintenance and repair personnel.

ETPs are divided into personnel of consumer organizations and personnel of electric power industry organizations.

Electric power enterprises include hydroelectric power plants, thermal networks, electrical networks and substations, electricity sales companies and other enterprises that not only generate electric current, but also transport and distribute it.

Consumers include all other enterprises and individual entrepreneurs who buy current to solve their business problems.

There is another fairly large category of workers who are assigned Group I for ES, but they do not belong to the ETP - we will talk about their training separately in this article.

Who can provide electrical safety training?

A responsible person from among the electrical personnel with an electrical safety group of at least III, who has been trained and appointed by order of the enterprise, can assign electrical safety group I (i.e., conduct instruction).

Order for the enterprise

In organizations (enterprises) with a small number of employees, in which a responsible person has not been appointed, the instruction is carried out by the head of the organization (he must also be certified accordingly).

It is also possible to conclude a civil contract or a service contract for reading electrical safety instructions with a person who has the appropriate permits.

Procedure for conducting briefing

All non-electrical personnel at each enterprise are required to be given instructions on electrical safety rules by management in order to be assigned group 1 and further allowed to perform their duties using electronic equipment. instruments and apparatus.

For non-electrical personnel, briefing has the right to be carried out by an employee with an electrical safety clearance group of at least 3, who is authorized by order of the enterprise.

The administrative document also approves:

- list of professions with the first group of ES;

- training program;

- briefing log form.

For those newly hired at the enterprise, electrical safety instruction for non-electrical personnel is combined with induction on occupational safety or with what is carried out at the workplace.

Information about the briefing is recorded in the Registration Journal with the obligatory signature of the person being instructed. As a result of the lessons, an oral check of the consolidation of the studied topics is carried out. After which 1 group is assigned according to electronic security (with a corresponding entry in the Journal).

Note! The frequency of refresher training for employees in group one is 12 months. This procedure does not depend on whether unscheduled classes with an instructor are held within one year

Who has the right to conduct

Assignment of group 1 in electrical safety is carried out by order of the head of the institution. It defines:

- the employee responsible for conducting the training;

- frequency of training;

- person exercising control.

A person from among the electrical engineering personnel who has group 3 or more can conduct instructions and assign group 1 in electrical safety.

If there are no such people in the institution, then the manager can order to send any employee to training in a special center. Having received group 3 in electrical safety, such an employee can conduct regular safety courses, including electrical ones.

Useful video on the topic:

For which workers is it necessary?

Interaction with any electrical devices, installations, or equipment in production requires compliance with safety regulations and is entrusted to employees with specific qualifications.

The first electrical safety group is given to non-electrical personnel who, in their work activities, use tools that do not require special skills.

Non-electrical personnel are considered to be:

- administrative employees not involved in the installation, maintenance and repair of electrical appliances;

- office employees using household and office equipment in the production process.

This category of workers is assigned by default 1 electrical safety group, but first an authorized person conducts appropriate instruction and verifies the acquired knowledge through testing or oral questioning.

The training course is basic and introductory, as it is conducted before personnel begin to perform an employment contract.