Who needs electrical safety training?

For ease of understanding, we will divide all personnel into “categories”:

- electrical (electrical) personnel (workers dealing with electrical equipment, electrical installations or power tools). This category of workers is assigned electrical safety group II-V (with the issuance of certificates);

- non-electrical personnel (workers who are not directly related to the repair and installation of electrical equipment, but use electrical devices to perform their duties (PC, printer, fax, other electrical devices) and perform work that may pose a risk of electric shock). This category of workers is assigned electrical safety group I (without issuing certificates).

The concept of induction training on electrical safety does not exist. Electrical safety training is carried out only for assignment to group I.

And to assign an employee a higher group, i.e. II – V gr., here you won’t get by with simple instructions. To do this, the employee must undergo a special training course at the training center in accordance with the training programs. Training programs differ in content for different qualification groups. After testing knowledge and passing exams, the employee is issued a certificate for the appropriate access group.

Based on the above, electrical safety training is carried out for all employees of the organization, except electrical personnel.

And the concept of “instruction” is applicable only for workers with electrical safety group I.

Purpose of instruction

The purpose of conducting specialized electrical safety training is:

- explanation of the operating features of complex electrical equipment and the specifics of production of a particular enterprise;

- prevention of injuries and harm to health in case of incorrect handling of equipment;

- preventing damage to complex technical equipment, causing material damage to the operation of the enterprise;

- clarification of labor safety standards and regulations when working with electrical equipment;

- study of the operating features of electrical equipment in specific production conditions.

Moreover, such instruction is carried out both in relation to newly arrived employees of the enterprise, and in relation to workers at a certain frequency to replenish knowledge or when new equipment arrives.

Working with electrical appliances of complex design always carries the risk of injury, burns and death if they are handled incorrectly or with laxity.

Therefore, not only employees of the occupational safety department and responsible managers, but also the workers themselves must take a responsible approach to electrical safety instructions.

Instruction for employees who do not require special permission when working with electrical equipment is carried out in order to prevent injuries and the occurrence of a fire hazard in the organization.

What are the types?

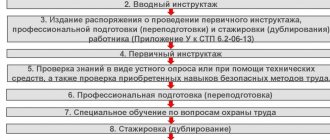

Types of electrical safety training are divided according to the occupational safety classification:

- Introductory - when an employee enters a job (student for internship, assigned to duties or transferred to another position).

- Primary – also upon entry into a position after successful completion of induction training. Such instruction is carried out for a detailed study of production conditions and features of the technological process associated with electrical equipment.

- Repeated - carried out in relation to employees of the enterprise to consolidate acquired and acquire new knowledge in the field of electrical safety, as well as to obtain a category when working with electrical appliances.

- Targeted / unscheduled - carried out in relation to employees in the event of a temporary or permanent change in work functions, emergency situations or the arrival of new equipment.

Carrying out these types of instructions is associated only with the specifics of work activity, which directly relates to working with electrical equipment.

Frequency and timing of implementation at the enterprise

The frequency of electrical safety training is established by GOST and Order 74N of the Ministry of Labor of the Russian Federation.

This period should be from 3 to 6 months, taking into account the specifics of working with electrical equipment.

At the discretion of the organization’s management, this period can be reduced, which is documented by issuing a corresponding order and notes in the briefing log.

.

Introductory

Introductory training takes place in several stages:

- Issuing an order from the head of the enterprise to conduct briefings depending on the circumstances (targeted when certain consequences occur, introductory when hiring an employee, repeated when the corresponding deadline arrives).

- Development of a set of measures for conducting instruction, depending on its nature. The development of a plan and instructions for carrying out activities is carried out by the occupational safety specialist/unit and the person responsible for the electrical equipment operation area.

- Organization of theoretical and practical activities to instruct workers on working with electrical equipment.

- Consolidating the acquired knowledge during certification or testing and placing an appropriate mark on successful completion in a special journal.

This procedure is regulated not only by local acts of the enterprise, but also by labor legislation.

Unscheduled

The procedure for conducting unscheduled electrical safety briefings is somewhat different from the standard procedure.

The main difference is the circumstances of such events.

They can be either the occurrence of an emergency situation or a strong-willed decision of the organization’s management if there are suspicions of low qualifications of employees.

The procedure is also documented, however, the list of documents does not contain a schedule for conducting instructions due to the nature of this procedure.

Based on the results of the measures taken, management can draw conclusions and apply disciplinary measures against employees who were unable to complete the electrical safety training procedures.

Target

The procedure for conducting targeted instruction also differs. It is also associated with the occurrence of certain circumstances not related to the performance by employees of their main functions.

When new equipment arrives or a man-made disaster occurs, persons who do not have certain skills and approvals may be involved in the work only after conducting targeted instructions on electrical safety.

The procedure is similar to other types of briefing and is subject to mandatory documentation in the journal.

Sample order

An order to carry out relevant activities is issued through the issuance of a local regulatory act signed by the head of the organization and visas of a labor protection specialist and the head of the department carrying out work with electrical equipment.

This order is issued with the obligatory indication of the grounds for conducting the briefing, its type, the circle of persons involved, as well as the appointment of a responsible person.

This person is a labor protection specialist/engineer at the enterprise.

What documents should there be?

To conduct training with assignment to Group I, you must complete a number of mandatory documents:

- List of professions and types of work that require assignment to group I in electrical safety. This list is approved by a local document, as a rule, this is an order (instruction) for the enterprise.

- A training program for assigning electrical safety group I, which should contain general information on electrical safety, information about the effects of electric current on the body and recommendations for first aid in case of electric shock.

- Logbook for training on assignment of group I in electrical safety to non-electrical personnel.

Which employees should be interviewed?

Everyone, without exception, should have knowledge in the field of electrical safety, but at the same time it is necessary to carry out instructions:

- With employees who do not directly work with electrical receivers, that is, non-electrical personnel. This includes industrial cleaners, PC users, machine operators and others. That is, all persons who in their activities come into contact with devices operating on electric current.

- Electricians involved in the installation and repair of power equipment are required to know the structure of all devices and wiring diagrams. They undergo training according to a special program.

- Heads of departments, heads of sections and foremen must also undergo instructions given by their immediate supervisors.

Failure to provide instructions may result in negative consequences and penalties from supervisory authorities.

Who can provide electrical safety training?

A responsible person from among the electrical personnel with an electrical safety group of at least III, who has been trained and appointed by order of the enterprise, can assign electrical safety group I (i.e., conduct instruction).

Order for the enterprise

In organizations (enterprises) with a small number of employees, in which a responsible person has not been appointed, the instruction is carried out by the head of the organization (he must also be certified accordingly).

It is also possible to conclude a civil contract or a service contract for reading electrical safety instructions with a person who has the appropriate permits.

Employer's responsibilities to ensure electrical safety

Types of labor safety briefings

The employer's responsibilities include ensuring the labor protection of the enterprise. This is carried out through organizational and technical measures to ensure electrical safety:

- labor protection of electrical and technological workers;

- monitoring the compliance of electrical installations with performance standards and compliance with the personnel work rules specified in the technological documentation for them;

- organizing training and examinations on knowledge of electrical safety rules among electrical and technological workers;

- selection of electrical and technological employees, compliance with regular medical examinations, provision of personnel with instructions on labor and fire safety;

- keeping records and analysis of incidents of violations of the rules of interaction with electrical installations, related accidents, as well as eliminating their causes;

- informing state energy supervision employees about severe, massive and fatal industrial accidents and accidents that occurred at the operating sites of electrical installations;

- drawing up labor safety and job descriptions for electrical employees;

- compliance with the schedule and regularity of technical inspection, maintenance, repair, renovation and testing of electrical installations and equipment, including those used for construction;

The employer is responsible for the labor safety regulations of the enterprise

- carrying out the required tests of electronic equipment, using lightning protection equipment, electrical current measurement equipment and maintaining its records;

- providing electrical installations with the necessary tools, protection and fire extinguishing items;

- compliance with the requirements of state energy supervision employees;

- control of environmental safety during the operation of electrical installations;

- recording energy costs, rational use of electricity and taking measures to save electricity;

- ensuring safety and reliability of interaction with electrical installations.

Electrical safety training for electrical and electrical engineering personnel

Training on knowledge of the rules of work in an educational institution can be carried out both within one’s own organization and at a training center . For this purpose, special training programs must be developed.

There is a category of persons whose knowledge testing is carried out exclusively by the territorial commission of Energonadzor (a structure of Rostechnadzor). These include:

- Responsible for electrical equipment and occupational safety specialist

- three out of five members of the commission for testing knowledge of the rules of work in the institution, without fail the chairman and his deputy.

These responsible persons must have at least group V for electrical safety in all electrical installations, but if the rating is below 1 kV, it is enough to assign them group IV. If the organization has a power engineer, then appoint him as chairman, and if not, then appoint him as the head of the department that operates the power plant.

An occupational safety specialist can be appointed as a member of the commission, or even better, as a member of the commission-secretary. But there is no way to appoint him as chairman and deputy. There may be times when the organization is small and does not have its own certification commission. In this case, the entire ETP will have to undergo testing of knowledge of the rules of work in electrical installations at Energonadzor, and there they do not teach safe methods of working in electrical installations, they only test knowledge, and quite strictly.

The frequency of knowledge testing depends on the main factor - the employee’s direct work in electrical installations. If the employee himself is engaged in work in the establishment, then the inspection is annual. If he only organizes it, but does not take part in the work himself, it is enough to train once every 3 years.

In order not to be confused in which case it is necessary to conduct training in occupational safety and in which in electrical safety, you need to remember the following:

How to register for training

As noted earlier, a note indicating that the employee has been instructed to be entered in a special journal.

Contents of the column in the journal:

- the first column indicates the serial number;

- in the second column the full name and initials of the employee are written;

- in the third - position;

- in the next column there is space for the signature of the person being instructed;

- in the fifth column, the responsible person who conducted the instruction signs.

The journal requirements are as follows:

- The pages must be numbered and bound.

- On the last page the total number of sheets is indicated and the organization's stamp is placed.

- The start and end dates of the journal are written on the cover.

- Storage of the log is necessary for 5 years, unless a different period is provided for by local regulatory acts of the enterprise.

- When designing and filling out the journal, you must not make mistakes, blots, typos, and much more. This is a document that must be written in legible handwriting.

For whom should repeated occupational safety training be organized?

Repeated instruction is organized for workers who have undergone initial instruction. Workers who did not undergo it (were exempted from it in accordance with the established procedure) also do not undergo repeated instruction. If working conditions change for a certain category of persons who have not previously received instruction, they must first undergo initial instruction, and after a specified period - again.

All workers must undergo repeated instruction, regardless of their length of service. It can be organized individually or collectively. Collective retraining is possible for workers of the same specialty who perform the same (same type) work.

Targeted briefing

As a rule, it is issued in accordance with the order to carry out work for the persons taking part in it. This type of instruction is usually carried out when performing one-time work, holding public events within a particular organization, for example, holidays or corporate events, when performing work for which permits or other special documents are issued. Also, this type of instruction may be required if the consequences of an accident or natural disaster will be eliminated.

Question No. 5.32

Section 5.

List of questions Every farm and enterprise must have an annual action plan to ensure the safe work of personnel who come into contact with electrified machines, instruments, and tools.

The measures being developed should include safety briefings for workers and engineers, training of personnel in how to use electrified equipment, testing knowledge of electrical safety rules and, as well as methods of providing first aid to victims of the action.

If a household or enterprise has, in addition to low-voltage electrical installations with voltages above 1000 V, electrical safety cabinets or corners should be provided. The activities indicate the persons conducting introductory and periodic briefings and who are responsible for maintaining the relevant briefing logs, as well as other technical documentation.

The training program is developed for each specific workplace. The instructions are carried out by the work manager or safety engineer, or the person responsible for electrical equipment. A newly arriving employee undergoes induction training and is assigned to an experienced specialist who has a safety group of at least third.

The activities include payment for staff training.

At the workplace, workers undergo primary, periodic and extraordinary briefings, and when working on assignments, they undergo targeted briefings.

Initial instruction on labor protection is carried out before

Who belongs to electrical and non-electrical personnel

ETP (electrical technical personnel) is a category of workers who operate electrical installations and carry out commissioning, installation work, maintenance and repair of electrical equipment.

This category includes:

- management of electrical installations - administrative and technical personnel.

- direct performers - operational, maintenance and repair personnel.

ETPs are divided into personnel of consumer organizations and personnel of electric power industry organizations.

Electric power enterprises include hydroelectric power plants, thermal networks, electrical networks and substations, electricity sales companies and other enterprises that not only generate electric current, but also transport and distribute it.

Consumers include all other enterprises and individual entrepreneurs who buy current to solve their business problems.

There is another fairly large category of workers who are assigned group I according to ES , but they do not belong to the ETP - we will talk about their training separately in this article.

Who needs instruction and why?

The employer is responsible for occupational safety. Therefore, enterprises of all types of activities and ownership are interested in the training service. After all, the safety of every employee of the enterprise depends on the regularity and quality of briefings, which are part of the training process. Statistics say that about 80% of emergency incidents and accidents occur due to the “human factor”. Among the main reasons for violation of safety and labor protection rules are:

- loss of vigilance;

- ostentatious courage, competitive spirit, thirst for risk;

- difficult working conditions, resulting in a fall from a height or an electric shock.

Allows for maximum reduction of occupational injuries

Regular training, forcing workers to never forget about possible dangers and their consequences.

What is the briefing for?

Introductory training in the field of electrical safety is necessary for:

- In order to explain to employees what technically complex equipment they will have to work on.

- Knowledge of specific production features.

- For preventive purposes, to avoid injury when handling power equipment.

- To ensure that there is no damage to the equipment.

- Knowledge in the field of working with electrical equipment.

- Gaining skills in working with technical devices in production.

All newly arrived employees, as well as experienced employees, must receive instructions from their immediate supervisors. If work is carried out with complex mechanisms, then this always poses a danger from burns to death, therefore, at the legislative level, all measures are provided to prevent these circumstances.

Preventive measures to prevent injury to employees are necessary.

Briefing for group 1 on electrical safety for office workers

In contrast to classes for electrical personnel, instruction on electrical safety in the workplace for those applying for group I is carried out according to a different scheme.

First, the manager issues an order in which he appoints one of the employees responsible for conducting the training.

Second, the Order approves the list of professions for training.

Third Selected employees undergo a 4-hour course directly on the job under the supervision of a responsible employee.

Fourth, how they learned the material will be shown by an oral survey, which is arranged at the end of the lesson.

The results of the course (i.e. assignment to group I) must be recorded in the electrical safety briefing log.

Who can conduct electrical safety training for 1 group

The general rule for conducting electrical safety training in 2021 is the qualifications of the responsible employee. He must belong to electrical personnel and have at least electrical safety group III (up to 1000 V).

In small organizations that are not related to energy and complex industries, such a specialist may not be available. In this case, the manager can do this, but first he himself must obtain group III in electrical safety.

- Ready-made solutions according to current legislation

- More than 3,000 completed templates

- Opportunity for expert support