Features of assignment of the 1st group in electrical safety for non-electrical personnel

In accordance with the current legislation of the Russian Federation, employees of all enterprises are required to be trained in occupational safety, fire safety and electrical safety.

In the field of electrical safety, personnel must be instructed and trained with the assignment of appropriate access groups. In this article we will consider the procedure for training, conducting instructions and assigning the 1st group to non-electrical personnel. Non-electrical personnel: the work is not related to the maintenance of any equipment, but there is a risk of electrical injury (for example, when connecting electrical appliances to the network); This category may include office workers, managers, accountants, etc.

Regulations:

- Rules for the technical operation of consumer electrical installations (PTEEP), approved. By Order of the Ministry of Energy of Russia dated January 13, 2003 No. 6.

- Rules on labor protection during the operation of electrical installations (POT EE), approved. By Order of the Ministry of Labor of Russia dated July 24, 2013 No. 328 n.

- The procedure for training in labor protection and testing knowledge of labor protection requirements for employees of organizations, approved. Ministry of Labor of Russia No. 1, Ministry of Education of the Russian Federation No. 29, resolution of January 13, 2003.

PTEEP, clause 1.4.4.: “Non-electrical personnel performing work that may pose a risk of electric shock are assigned Group I for electrical safety. The list of positions and professions requiring assignment to personnel of electrical safety group I is determined by the head of the Consumer. Personnel who have mastered the electrical safety requirements related to their production activities are assigned group I with registration in a journal of the established form; no certificate is issued.

Assignment to group I is made through instruction, which, as a rule, should end with a knowledge test in the form of an oral survey and (if necessary) a test of acquired skills in safe working methods or providing first aid in case of electric shock. The assignment of electrical safety group I is carried out by an employee from among the electrical technical personnel of a given Consumer with an electrical safety group of at least III. Assignment of electrical safety group I is carried out at least once a year .

Who is assigned 1st EB group

In accordance with the requirements of Order No. 6 of the Ministry of Energy dated January 13, 2003, all employees of the enterprise are divided into 3 parts: electrical, non-electrical and other personnel. The meaning of this division is that people from the first category have special access to the maintenance of electrical networks and electrical equipment, and workers from the second only use this equipment to carry out production activities. Other personnel include people who do not work with electrical appliances.

Electrotechnological personnel can perform the following functions:

- administrative and technical;

- repairs (permanent or urgent only);

- operational.

These are people whose responsibilities include maintaining electrical networks and ensuring the functionality of equipment connected to these networks. Depending on the qualifications and functions performed, they are assigned electrical safety group 2, 3, 4 or 5.

Organization of training and registration

To conduct instruction at the enterprise, a special educational and methodological complex must be developed for conducting instruction, testing knowledge and assigning group 1 in electrical safety to non-electrical personnel (for each structural unit of the enterprise).

- View Order on the procedure for assigning Group I for electrical safety

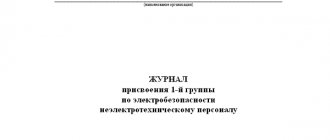

Personnel who have mastered the electrical safety requirements related to their production activities are assigned group I and documented in a journal. The form of the journal is not established in the Labor Safety Rules for the Operation of Electrical Installations, but the requirements for the content of records are given: ... the journal must contain:

- surname, name, patronymic of the employee;

- his position;

- date of assignment of group I for electrical safety;

- signature of the person being checked and the inspector.

You can buy such a magazine or make it yourself.

How is permission to work granted?

If an employee is certified in electrical safety group 1, then he must be allowed to perform the work independently.

To do this, it is recommended to use the following algorithm:

- Prepare an administrative document about the internship, which should appoint a person responsible for conducting the internship, as a rule, this is trained personnel. The document signed by the head of the structural unit must be signed by the trainee and the person assigned to him. The internship time ranges from 2 to 14 shifts, depending on the complexity of the work performed.

- At the end of the internship, an administrative document is issued again stating that the internship has been completed in full, and the employee can be allowed to perform work independently. The employee is familiarized with this document.

This is how approval for electrical safety group 1 is obtained. Orders or instructions are stored in personal cards, so it will be easier to find them.

How to conduct training?

You can choose the form of training and instruction yourself: self-study by staff of the necessary lecture materials, electrical safety instructions and additional materials, or face-to-face classes with an “instructor.” But at the end of the educational process, it is necessary to conduct a knowledge test in the form of an oral survey and (if necessary) a test of acquired skills in safe ways of working or providing first aid in case of electric shock. Those who successfully pass the knowledge test are assigned electrical safety group I, and a corresponding entry is made in the journal.

Assignment of group I is carried out by an employee from among the electrical personnel who has group III in electrical safety , appointed by order of the head of the organization.

SAFETY REQUIREMENTS FOR OPERATING ELECTRICAL EQUIPMENT

5.1. Equipment with external power, depending on the method of protection against electric shock, is divided into class IV: - equipment of safety class I, in addition to basic insulation, has a grounding contact of the power cord plug or a clamp on the body with a permanent connection to the network, which serves to connect those accessible to touch metal parts to an external grounding device; — devices of safety class 0I, in addition to basic insulation, have a clamp for connecting accessible metal parts to an external grounding device; the power cord plug does not have a grounding contact; — electrical equipment of safety class II (with double or reinforced insulation, has, in addition to the main insulation, additional insulation, a sign at the entrance of the power cord into the housing) and does not require protective grounding or grounding; — class III devices are powered from an isolated current source with an alternating voltage of no more than 24 V or a direct voltage of no more than 50 V and do not have circuits with a higher voltage and do not require protective grounding or grounding. 5.2. If the degree of protection (class) is not indicated in the markings on the equipment or in the operating instructions (passport) or they are lost, then such devices must be checked by engineering and technical personnel to determine their suitability for further safe operation. It is prohibited to allow the use of such devices by customers (for example, refrigerators) if the degree of their protection is unknown. 5.3. To protect against electric shock, all accessible metal parts of Class I and Class 0I equipment must be grounded or neutralized. 5.4. The continuity of the circuit between the protective grounding terminal on the electrical installation and the grounding terminal on the panel or protective grounding bus must be checked by personnel inspection at the beginning of each work shift. It is prohibited to supply mains power to the electrical installation if the continuity of the protective grounding circuit is broken. 5.5. In the room where electrical equipment is operated, radiators and metal pipes for heating, water supply, sewer and gas systems must be covered with wooden gratings or other dielectric barrier devices, and the floors must be non-conductive. 5.6. Personnel are prohibited from connecting electrical equipment to the network if the insulation of the power cord and plug body is damaged, as well as other defects that may cause personnel to touch live parts. 5.7. If a malfunction is detected during the operation of electrical equipment, personnel must immediately disconnect the faulty device from the network and report this to their immediate supervisor. 5.8. It is prohibited to work with faulty equipment; work can be resumed only after the fault has been eliminated and there is a corresponding entry in the maintenance log by the person responsible for the serviceability of the electrical equipment. 5.9. It is prohibited to disconnect electrical equipment by pulling the plug from the socket by the cord; force must be applied to the body of the plug. 5.10. It is prohibited to transport carts over wires and cables, to step on electrical cables or cords of electrical equipment, to carry running electrical devices or leave them plugged in without supervision, or to throw plugs on the floor. 5.11. When connecting stationary equipment, the use of adapters and extension cords (except for special stabilizing devices) is prohibited, for which a sufficient number of plug sockets must be provided in the premises. 5.12. Workers are prohibited from using electrical equipment without first familiarizing themselves with the principle of its operation and the rules of safe operation (passport or instructions). 5.13. It is prohibited to check the functionality of electrical equipment in rooms that are not suitable for use with conductive floors, damp, and do not allow accessible metal parts to be grounded (for classes 0I and I). 5.14. Personnel are prohibited from independently repairing faults in electrical equipment; repairs are carried out by a worker with the required qualifications and only after disconnecting the device from the network. 5.15. It is prohibited to use electric stoves with open spirals, electric heaters without protective enclosures, and other electrical receivers with live parts that can be touched indoors. 5.16. It is prohibited to place the wires of portable lamps and electrified tools on wet surfaces, hot objects, or in places where they may be subject to friction, twisting, or tension. Wipe electrical installations connected to the network with wet rags. Wash the walls where electrical appliances are installed, cables and wires are laid. Clean the premises using a watering hose near the switchgear and electric motors installed on the floor.

Brief summary

To properly organize the assignment of electrical safety group I to the organization’s personnel, it is necessary to:

- Develop basic local documents: Regulations on conducting briefing, testing knowledge and assigning Group I in electrical safety to non-electrical personnel, Instructions and Program for conducting briefing, testing knowledge and assigning Group I in electrical safety to non-electrical personnel.

- Approve the List of positions and professions of workers classified as non-electrical personnel and who must undergo training and knowledge testing to be assigned group I in electrical safety.

- Appoint a person responsible for conducting instructions and assigning group I from among electrical personnel with an electrical safety group of at least III. If there are no such employees at the enterprise, then either: hire such a person from outside (with the execution of a civil contract) or undergo certification.

- Once every 12 months, conduct instruction with mandatory testing of acquired knowledge. Record the result in a journal.

Frequency of certification

Frequency of electrical safety certification

After certification, it is necessary to periodically organize knowledge tests of employees. The frequency of certification is once a year.

Periodic certification is organized as follows:

- A list of employees subject to certification is being prepared.

- Employees are invited to the training class and are interviewed in the same way as during the initial certification. This is carried out by employees certified in electrical safety and assigned by order.

- Next, lectures are read, and then employees are asked questions about the material they have learned.

- Information about the periodic certification carried out is entered into the same Journal in which the employees and the person who interviewed them sign.

That is, in general, periodic certification is no different from primary certification.

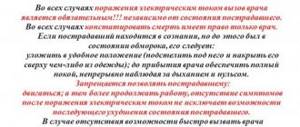

IMPACT OF ELECTRIC CURRENT ON THE HUMAN BODY

2.1. Electric current has biological, electrolytic and thermal effects on the human body. 2.2. Biological is expressed in irritation and excitation of living cells of the body, which leads to involuntary convulsive muscle contractions, disruption of the nervous system, respiratory and circulatory system. In this case, fainting, loss of consciousness, speech disorder, convulsions, and breathing problems (even stopping) may occur. In case of severe electrical injury, death can occur instantly. 2.3. Electrolytic effects manifest themselves in the decomposition of blood plasma and other organic liquids, which can lead to a disruption of their physical and chemical composition. 2.4. Thermal exposure is accompanied by burns of parts of the body and overheating of individual internal organs, causing various functional disorders in them. The resulting electric arc causes local damage to human tissues and organs. 2.5. According to the severity of electrical injuries, they are classified into four degrees: - I degree - convulsive muscle contraction without loss of consciousness; — II degree – convulsive muscle contraction and loss of consciousness; — III degree – loss of consciousness and dysfunction of cardiac activity and breathing; — IV degree – clinical death. 2.6. Burns are divided into four degrees: - I degree - redness of the skin; — II degree – formation of bubbles; — III degree – charring of the skin; — IV degree – charring of subcutaneous tissue, muscles, blood vessels, etc... 2.7. Types of electric shock: - electrical burns, divided into current (contact), arc and combined; - electrical marks (signs) - specific damage to the skin by electric current; - metallization of the skin - penetration into the upper layers of the skin of the smallest particles of metal (welding work), melted under the influence of an electric arc; - mechanical damage - a consequence of sharp involuntary convulsive contractions of muscles under the influence of current or a fall from a height when released from the action of electric current; — electroophthalmia – damage to the organs of vision (electric arc); — electric shock is a kind of severe neuroreflex reaction of the body, accompanied by serious disorders of blood circulation, breathing, and metabolism; - electric shock - stimulation of living tissues of the body by electric current, accompanied by involuntary convulsive muscle contractions. 2.8. The severity of electrical injuries depends on the strength of the current passing through a person, the type of current, the time of exposure, the physiological state of the body (individual properties) and environmental conditions. 2.9. Current strength. The overall reaction of the body depends on its magnitude. The maximum permissible value of alternating current is 0.3 mA. When the current strength increases to 0.6-1.6 mA, a person begins to feel its effect, and a slight trembling of the hands occurs. With a current strength of 8-10 mA, the muscles of the arm (in which the conductor is clamped) contract, and the person is unable to free himself from the action of the current. AC current values of 50-200 mA or more cause cardiac fibrillation, which can lead to cardiac arrest. 2.10. Type of current. The maximum permissible value of direct current is 3-4 times higher than the permissible value of alternating current, but this is at a voltage not higher than 260-300 V. At higher values, it is more dangerous for humans due to its electrolytic effects. 2.11. Resistance of the human body. The human body conducts electricity. Electrification occurs when there is a potential difference between two points in a given organism. It is important to emphasize that the danger of electrical accidents does not arise from simple contact with a live wire, but from simultaneous contact with a live wire and another object at a difference in potential. The resistance of the human body is made up of three components: the resistance of the skin (at contact points), internal organs and the capacity of the human skin. The main resistance value is the superficial skin (up to 0.2 mm thick). When the skin is moistened and damaged in places of contact with live parts, its resistance drops sharply. 2.12. The resistance of the skin decreases greatly with increasing density and area of contact with live parts. At a voltage of 200-300 V, an electrical breakthrough occurs in the upper layer of the skin. 2.13. Duration of current exposure. The severity of the injury depends on the duration of exposure to the electric current. The time it takes for the electrical current to pass is critical in determining the extent of injury. For example, marine fish (electric eel rays) produce extremely unpleasant discharges that can cause loss of consciousness. However, despite a voltage of 600 V, a current of 1 A and a resistance of approximately 600 ohms, these fish are not capable of causing a fatal shock because the duration of the discharge is too short - on the order of several tens of microseconds. 2.14. With prolonged exposure to electric current, skin resistance decreases (due to sweating) at the contact sites, increasing the likelihood of current passing during a particularly dangerous period of the cardiac cycle. A person can withstand a lethal alternating current of 100 mA if the duration of exposure does not exceed 0.5 s. 2.15. The path of electric current through the human body. It is most dangerous when the current passes through vital organs - the heart, lungs, brain. 2.16. When a person is injured, 6.7% of the total electric current passes through the “right arm - legs” path through the human heart. During the leg-to-leg path, only 0.4% of the total current passes through the human heart. 2.17. From a medical point of view, the passage of current through the body is the main traumatic factor. 2.18. Frequency of electric current. The frequency of electric current accepted in the energy industry (50 Hz) poses a great danger of convulsions and ventricular fibrillation. Fibrillation is not a muscular response but is caused by repetitive stimulation with a maximum sensitivity of 10 Hz. Therefore, alternating current (with a frequency of 50 Hz) is considered three to five times more dangerous than direct current - it affects human cardiac activity. 2.19. By individual characteristics of a person (or physiological state) we mean: diseases of the skin, cardiovascular system, lungs, nervous diseases and everything that increases the pace of the heart (fatigue, excitement, fear, alcohol, thirst) contributes to an increase in the severity of electric shock. 2.20. Environmental conditions and the premises themselves in which electrical installations are located are factors influencing the severity of electric shock. 2.21. Premises are divided into three categories: - premises without increased danger; — high-risk premises; - especially dangerous premises. Premises with increased danger are characterized by the presence of at least one of the following conditions: - conductive dust, soot; — dampness – relative air humidity exceeds 75% for a long time; — high air temperature – exceeds 35°C for a long time; - conductive floor - metal, reinforced concrete, stone, earthen; - the ability to simultaneously touch metal elements of technological equipment connected to the ground or metal structures of a building and metal casings of equipment. 2.22. Particularly dangerous premises are characterized by the presence of: - high air humidity - close to 100%, “dripping from the ceiling”; — a chemically active environment that has a destructive effect on the insulation of electrical equipment; - simultaneous presence of two or more signs of premises with increased danger. 2.23. Premises without increased danger, i.e. in which all the above conditions are absent. 2.24. There is no category of safe premises where electrical installations are used. There is always a danger of electric shock in any premises! 2.25. Employees notify their immediate supervisor of any detected malfunctions. In this case, starting work is allowed after troubleshooting and only after receiving permission from the immediate supervisor.

How to organize certification

Organization of electrical safety certification at the enterprise

In order not to violate the requirements of regulatory documents of intersectoral Rules, any manager should organize this work.

For this it is recommended:

- To have an employee on staff responsible for this area, since this topic concerns safety, this employee could be a labor protection engineer.

- The safety engineer himself must also be trained and certified as administrative and technical personnel in electrical safety.

- Every year and as necessary, the responsible employee must prepare lists of employees who need to undergo certification. It is possible that these lists are constantly updated as people change. In this case, it is important not to miss the certification of a single person.

- The updating of the Instruction Program, registration of the Journal and preparation can also be entrusted to the responsible employee, since it will be easier to ask from one person.

- The annual update of orders on the composition of the certification commission and monitoring the certification of its members also falls on the shoulders of the safety engineer.

- Orders for internships and permission to work are issued by personnel department employees, but control over their publication and familiarization of employees with them is carried out by an occupational safety engineer.

If it is impossible for the enterprise to organize a commission to conduct certification, then it is recommended to enter into contractual relations with training centers, the latter will send a teacher who will conduct the conversation.