What kind of occupational safety magazines are there?

The legislation of the Russian Federation in the field of labor protection (Labor Code of the Russian Federation, GOST 12.0.004-2015, Resolution of the Ministry of Labor of the Russian Federation dated December 17, 2002 No. 80) requires Russian employers to keep logs:

- registration of introductory briefings on labor protection (clause 8.6 GOST 12.0.004-2015);

- registration of labor safety briefings that are not introductory;

- taking into account instructions on labor protection (clause 5.10 of the appendix to the resolution of the Ministry of Labor of the Russian Federation dated December 17, 2002 No. 80);

- accounting for the issuance of instructions on labor protection (clause 5.10 of the appendix to the resolution of the Ministry of Labor of the Russian Federation dated December 17, 2002 No. 80);

- registration of accidents (Article 230.1 of the Labor Code of the Russian Federation).

These registers are the main journals on labor protection at Russian enterprises.

The list of labor safety documents that an employer needs to have was prepared by ConsultantPlus experts. You can view it by getting free access to the system.

Types of safety training

The enterprise, in accordance with GOST 12.0.004-90, conducts the following safety training:

- Target.

- Primary in the workplace.

- Introductory.

- Unscheduled.

- Repeated.

Introductory training is carried out when hiring new employees, regardless of profession, education, qualifications, working conditions, etc. The training is carried out by a safety engineer in accordance with developed and approved instructions.

Initial training at the workplace is carried out before the employee starts work. Professions that require this training are determined by the head of the enterprise in agreement with the safety engineer and heads of structural units. Basically, these are specialties associated with the use, maintenance and repair of specialized equipment and tools, as well as working with dangerous and harmful working conditions. This briefing is carried out by the heads of structural divisions individually with each newly arrived employee.

The specialist conducting the training tells you what can be done, describes and shows the procedure, and also explains what is prohibited. In some cases, an internship and entry into work permit documents are required.

Repeated training must be carried out with all employees of the enterprise at least once every six months. It is carried out by a safety engineer or the head of a structural unit. Its main purpose is to test the existing knowledge of employees and, if necessary, fill gaps.

Unscheduled briefing must be carried out with all employees of the company when new labor protection standards come into force, the introduction of new equipment or changes in the production process, identification of facts of safety violations, in case of accidents and emergencies, at the request of inspection authorities, etc. It is carried out safety engineer or head of a structural unit in the scope and subject matter depending on the reason for this training.

Targeted training is the acquisition of knowledge on a specific one-time function (for example, emergency response, etc.)

All safety training must be recorded in appropriate logs.

Who is responsible for maintaining labor safety logs?

By separate orders of the company management, those responsible for maintaining:

- both types of briefing logs;

- accident register.

The competence of persons appointed by management to be responsible for maintaining these labor safety logs includes:

- timely entry of necessary information into them;

- prompt provision of occupational safety journals for use by other specialists, as well as their subsequent acceptance back for storage.

Regarding log books and issuing instructions, management can also appoint an employee responsible for maintaining and storing them. If the document is developed for a specific structural unit of the company, its storage should be carried out by the head of this unit.

Legal regulation and standards for training logs

The main standard, in accordance with which the maintenance and completion of training logs is ensured, is the national standard GOST R 12.0.004-90 “SSBT Organization of Occupational Safety Training”. This standard provides for the introduction of a unified form of such a document, as well as regulation of the procedure for its completion, organization and maintenance.

Thus, the training log itself must be kept by the occupational safety engineer or the employee performing his duties. Employees who are responsible for conducting training must receive these logs from him. Log books are usually produced by printing in accordance with the established form and are purchased in advance in a ready-made form. The enterprise is only obliged to carry out or check the numbering of sheets and ensure the binding of such a magazine with the obligatory sealing of the ends of such firmware.

Each log must be certified either by the responsible labor protection engineer or by the head of the enterprise. In addition, all journals present at the enterprise, including in its various divisions, must be maintained in a single form. The storage period for training logs in the enterprise archive is ten years from the date of their closure.

Specifics of filling out occupational safety logs

Now let’s look at what nuances an employer should pay attention to when filling out occupational safety logs.

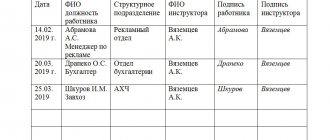

For both types of training logs, it is important to pay attention to:

- the presence of signatures of the person being instructed and the person instructing opposite each entry on the instruction;

- indication of the full name and positions of the instructed employee and instructor, the date of each briefing.

The procedure for conducting introductory training on labor protection is described in detail in the Guide from K+, access to which can be obtained free of charge.

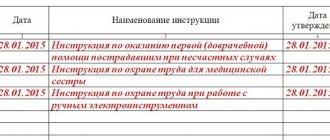

To fill out the instruction logbook, the following are of greatest importance:

- correct indication of the date of registration of the instruction and the beginning of its use;

- correct title of documents;

- presence of signatures of the responsible employee confirming the fact of acceptance of the instructions for registration.

With regard to the instruction log, special attention should be paid to:

- correct indication of the date of issue of instructions upon request;

- indication of the full name of the employees receiving instructions, as well as the presence of their signatures.

When filling out the accident log, it is important to indicate:

- the exact date, time, location of the incident;

- all necessary information about the victim;

- measures taken to eliminate the causes of the accident.

These nuances of filling out occupational safety logs are among the most critical. This does not mean that other columns or paragraphs of the document need not be filled out at all. It is also necessary to work with them, but errors or omissions of entries in them may not be as critical as in the elements of occupational safety journals reflected above.

How to fill out the briefing log correctly

Filling out the workplace briefing log, the sample of which is always regulated by the management of a particular organization, is carried out according to certain rules:

- the journal must be laced to avoid falsification of the document;

- pages of the journal are subject to mandatory numbering;

- Each page of the document must bear the signature of the manager;

- For all divisions of one organization, the journal form must be the same.

The document itself is kept by the responsible labor protection engineer. During the briefings, the engineer issues logs to the heads and foremen of the departments, who, after filling out the logs, return them back.

All data is entered into the journal only in chronological order, and each entry must contain the full name and position of the instructed and instructors, the date of the event and a mark on completion of the instruction.

If on the day of the briefing one of the employees was absent from the workplace, he is obliged to undergo training immediately after returning to work, and the date in the log is not “backdated”, but current at the time of the event.

Where to download free occupational safety magazines

You can download samples of occupational safety magazines on our portal. The relevant sources are compiled taking into account the criteria that we outlined in the article.

You can download occupational safety magazines using the following links:

- For more information about the log of introductory briefings, read the article “Journal of introductory briefings on labor protection - sample.”

- For information about the logbook for briefings that are not introductory, read the article “Logbook for registration of workplace briefings—sample.”

- The log of labor safety instructions is available in the article “Log of labor safety instructions - form and sample.”

- The logbook for issuing labor safety instructions can be downloaded here.

- The accident log can be downloaded here.

Read more about the journal in the article “Journal of Occupational Accidents”.

Workplace induction log: standardized form

The recommended form of the “Logbook for registration of workplace training” is approved by the provisions of GOST 12.0.004-2015 (Appendix A.5). The same regulatory act regulates the requirements for maintaining the Journal:

- it is created and maintained exclusively on paper;

- the magazine must be stitched, numbered, and sealed in the prescribed manner;

- information is entered into the “Journal of Instruction at the Workplace” by hand, and only by a person whose authority is approved by the order of the enterprise;

- Each entry must be confirmed by the personal signatures of the person being instructed and the person instructing.

download the on-the-job training registration log ( as well as see an example of filling it out) below.

Results

So, we looked at how to fill out occupational safety journals, which are considered the most popular in personnel management. When working with columns of occupational safety journals, it is necessary to pay attention to the correctness of filling out each of them, but there are elements of the structure in which, if possible, errors should be fundamentally eliminated.

Sources: Labor Code of the Russian Federation

You can find more complete information on the topic in ConsultantPlus. Free trial access to the system for 2 days.

Why is it needed?

Cover of the registration log and briefing at the workplace

Safety briefing is necessary in order to prevent emergency incidents that may occur to workers when performing their job duties without complying with certain requirements. The regulation of these requirements is directly related to the production process in the organization, the equipment and raw materials used, and the severity of harmful factors in working conditions.

Employees undergo initial briefing upon entry to work; repeated instructions can be carried out both planned and unscheduled, for example, upon the arrival of new equipment used in production cycles. Repeated training of personnel is carried out once every six months to update and update information. If necessary, these events can be held more often. There are situations in which there is a need for targeted instruction, which is recorded in the workplace instruction log. Such situations include:

- Organizational actions for holding mass events;

- One-time, one-time work;

- Activities requiring separate permits and admissions;

- With the participation of workers in eliminating the consequences of natural and man-made disasters.

Data on the instructions carried out can be entered both in the general logbook of registration of instructions at the workplace, and in a separate document intended for certain types of instructions.

Important! Initial training must be carried out with all persons involved in production activities, including temporary workers and persons working at home using equipment, machinery or raw materials provided by the employer.

Workplace briefing logbook form