The journal for recording the issuance of labor protection instructions is an important document for recording the information and distribution of labor protection instructions to employees. Each company within whose walls they engage in production may have a similar document. At least this is stated in the laws relating to the Labor Code. Controlling organizations strictly monitor this.

- Form and sample

- Free download

- Online viewing

- Expert tested

FILES

Why is it needed?

The journal is a way to reflect to whom and in what form labor safety instructions were issued. If an accident occurs at work due to failure to comply with labor safety instructions, the employee responsible for informing others may incur both administrative and criminal liability for failure to fulfill his duties. The completed log book impartially records who issued what and to whom, and whether briefing was carried out with a specific team member.

Having such proof of the fulfillment of their duties in hand, the manager, foreman or other person responsible for industrial safety minimizes their risk of going to prison by a court decision due to an accident.

Can the State Labor Inspectorate fine an enterprise that does not maintain a log of issuing labor safety instructions?

If during the inspection it turns out that the enterprise does not keep this log at all, the GIT inspector may recommend starting one. He cannot impose a fine for this, since the Methodological Recommendations, which provide the recommended form of the document, are not a regulatory legal act, and the inspector has no legal rights to demand their full compliance. In the order, the inspector may recommend the development and maintenance of such a log.

By the way, on some sites that provide visitors with the opportunity to download occupational safety journals, it is sometimes written that since the Journal is a recommended document and not a mandatory one, it can be filled out in any way you like, even through a sheet of paper, even with a felt-tip pen. Actually this is not true. If the Journal is approved by an organization order, it becomes part of the document flow. Consequently, it is subject to all requirements in terms of filling out, storing, recording, etc. If the Journal is simply available, but not approved by order, it is indeed a paper that has no legal force. It is unlikely that it will help the company in any way in legal proceedings, for example.

Who fills it out

There is no fundamental significance in this moment. The head of the organization has the right to independently decide who is required to fill out this paper. It would be logical if the head of the structural unit who conducted the initial briefing at the beginning of the quarter (or other reporting period) started and kept the journal. The main thing is that this is stated in his job description or employment contract.

Important point! According to Letter of the Ministry of Labor dated September 15, 2016 No. 15-2/OOG-3318, all instructions are issued strictly against a signature in the journal. An employee’s record of issuance without his personal signature is unacceptable.

In practice, a situation often occurs that the personnel service of the enterprise is responsible for maintaining the journal, or the accountant assumes responsibility for informing employees and collecting their signatures to certify that they have read the instructions.

Purpose of the magazine

Legislative acts do not regulate the creation of a log, but it will be easier for occupational safety specialists to work if the document is created. And there are a number of reasons for this:

Know exactly who the instructions were issued to, so that there are no misunderstandings on controversial issues. For example, the head of the site accuses the OT service that the documents were not handed over to him and therefore he did not carry out instructions in a timely manner. At one time, the safety engineer looks into the magazine and finds the instruction number, date and signature of the careless boss.

Providing instructions for the unit can be arranged with due effect. After reviewing the records, it is easy to clarify which specific areas lack the necessary documents and what needs to be worked on. Even if the instructions were revised unscheduled, it is easy to find out whether it was issued against the signature of the site manager.

It is easy to do an analysis in departments about the issuance of documents, that is, whether all instructions are available at the workplace. If you find that some documents are missing, you can make notes for yourself and then fill in what is missing.

The employer, as a rule, is most interested in keeping a log, since it will be much easier to control. The resolution of controversial issues is especially affected. For example, one of the employees was injured and at the same time claims that he was not instructed, and the safety engineer checks from the issue log whether the instruction was received, and then whether he was instructed.

Despite the fact that it is not necessary to create a document, it is much easier to work with it, and control is never superfluous.

Is this form required?

The legislation provides for the possibility of independent formation of such documents in companies. The graphs can be changed at your discretion. The main thing is that the register should indicate

- organization,

- responsible persons,

- signatures of those to whom instructions were handed out.

The fact of such a change must be reflected in the company's accounting policies and stated in the relevant documents. Otherwise, the organization will face, at a minimum, administrative liability.

Therefore, most companies prefer to use standard forms, although they are not mandatory.

Some, in addition to information about the issuance of labor safety instructions, include in the log data on the issuance of fire safety instructions. This is quite convenient: an individual employee signs for issuing two types of instructions on how to stay safely at his or her workplace. Only such a change should be recorded by one of the manager’s orders.

Why do you need a fire safety training log in the workplace?

Mastering the theoretical part of safety precautions at an enterprise is a prerequisite for admitting a newly arrived employee to his workplace. In addition to introductory training, other types of classes are provided for employees, depending on their length of service at the enterprise or other special conditions. There are a total of 5 types of training for staff:

- - introductory;

- - primary;

- - repeated;

- — target;

- - planned.

It is unacceptable to treat filling out the instruction registration book as a mere formality. Indeed, in the event of an emergency at the enterprise, it will confirm that training sessions were conducted with employees. And any inspection by the fire department will first require a log.

The manager or person responsible for safety is responsible for the timeliness and correctness of filling out the log. The authorized employee must have perfect knowledge of the discipline being taught and have experience working at the enterprise in question. In addition, he is required to have personal qualities that will help ensure a safe environment in the enterprise.

Important! Often, upon arrival to a new position, an employee undergoes simultaneously training in fire safety and labor protection. In such a situation, appropriate entries in separate journals are necessary.

Journal components

The document has a simple and understandable structure. The very first sheet is the cover. For ease of use, it can be made of thick paper. It indicates the name of the organization to which he belongs, as well as the date.

Typically, only the start date of logging is indicated. And the end date is set only when a new one is started. In any case, the register has legal force with at least one filled-in number.

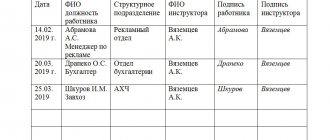

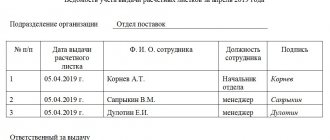

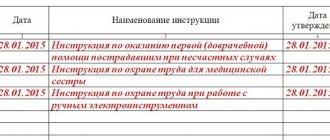

Under the cover there is a table with columns containing the following information:

- The sequence number of the line.

- Date of instruction.

- Full name of the issued instruction.

- Date of adoption of the instruction.

- Designation number of the issued document.

- The period planned for conducting a knowledge test based on the instructions issued.

- Full name, position, signature of the employee who records the issue.

Typically the journal is kept for a year or several years. After the 10-year period, it will need to be replaced in any case.

If we are talking not only about the adoption of an order, but also about informing, then the number of printed copies that was issued to employees is also indicated. The latter put their signature in the final column of the document.

Rules for filling out the journal

You need to know in what sequence to work with the document; first, it is recommended to download its sample. If a person is appointed responsible for maintaining the journal by administrative document, then this circumstance automatically acquires legal force.

List of important actions for maintaining a document:

- All pages must be numbered, the brochure must be stitched, and then sealed. It is important that if the sheet is torn out, the weight is noticeable. You can number it manually, or you can do it on a computer, it’s not so significant.

- Fill in clearly, leaving no gaps or lines. If they remain at the end of the page, it is better to mark it with the letter z. There is no need to try to fill out the information so that it fits on one line, as it will be difficult to read. Letters must be written clearly and legibly. If a mistake is made, you need to carefully cross out what is unnecessary, and at the bottom make a note with an asterisk “believe the corrected one.”

- Covering up mistakes with a proofreader is not recommended; it is not encouraged and can be regarded as a gross mistake.

- Fill in the lines with a pen; the use of markers and felt-tip pens is not allowed.

- If the journal has expired, it is stored in the archive for 10 years.

- It is very convenient and encouraged in practice to paste into the document the rules for its use and completion. Which will make it much easier:

- Establish a uniform procedure for filling out the document in the organization as a whole.

- To keep a journal. Prepare short descriptions of the names of instructions so as not to write long names.

- Although such standards have not been adopted at the legislative level, there are no prohibitions here. Entries in the journal must be made by the employee who issues occupational safety instructions and exercises control over this procedure.

- Entries in the document must be made by the employee appointed responsible for maintaining it, which is advisable to be written down in the administrative document. The work organization process is carried out as follows:

- Instructions must be issued to each production site manager against signature, personally. It is enough for one journal to be opened for the entire organization.

- The occupational safety specialist issues instructions to managers, and they, in turn, inform employees who reports to them.

- Safety instructions are located at workplaces and every employee is required to know their location; this requirement must be observed, it is regulated by the rules.

Nuances of filling

According to the existing law, namely paragraph 6 of the mentioned Methodological Recommendations of the Ministry of Labor, labor protection instructions must be reissued and revised at least once every 5 years. If this happens at the time of the existence of the previous journal (in which the old sample is mentioned), then there should be notes about the release of the new edition opposite each column with this document.

If several instructions of different types are issued to the same person, then a separate line is allocated for each of them. The names do not need to be entered separated by commas.

If an error is made in the journal for recording the issuance of labor protection instructions, the entire line is crossed out with a single line. Below is all the information from the very beginning. It is not allowed to write it with a pencil or skip lines. It is convenient to write a document using blue or black ink. It is impossible to fill it out electronically, since it is necessary to put “live” signatures of notified employees.

Results

Labor safety instructions are an important document in the document flow of an enterprise, the provisions of which the employee must comply with. The Ministry of Labor of the Russian Federation proposes to record them using 2 types of journals - to record these documents and to record their provision to employees.

The first type of journal will allow the employer to control whether the personnel register contains instructions that are necessary at the enterprise, based on the specifics of the positions on the staffing table, and also how timely they are taken into account. The second log will help the personnel officer track which employees have already been familiarized with the labor protection instructions, and who still have to do this.

You can consider other useful nuances on labor protection in the articles:

- “Where to start with labor protection at an enterprise (nuances)?”;

- “What are the storage periods for labor protection documents?”;

- “Order on the creation of a labor safety commission - sample”;

- “How to draw up a labor safety action plan (sample)?”

Sources: Labor Code of the Russian Federation

You can find more complete information on the topic in ConsultantPlus. Free trial access to the system for 2 days.