How to act

The current approximate training program for occupational safety and health in the workplace is given in Appendix B.2 to GOST 12.0.004-2015 “Interstate standard. System of occupational safety standards. Organization of occupational safety training. General provisions."

This GOST, together with this program, was put into effect by order of Rosstandart dated June 9, 2021 No. 600-st. It officially came into effect on March 1, 2021.

Moreover, the law allows you to choose. Thus, initial instruction on labor protection in the workplace can be carried out according to one of 2 options:

- According to the program under consideration, based on Appendix B.2 to GOST 12.0.004-2015 (taking into account the requirements of the law, internal rules, instructions on labor protection in the workplace and work safety, and other technical and operational documentation necessary for this).

Also see “Conducting targeted training on labor protection.”

- Directly according to instructions on labor protection and/or safe performance of work at a given workplace (or other internal rules necessary for instruction).

Also see “What you need to know about occupational safety instructions by profession.”

Initial briefing on labor protection - introduction

This article contains information that relates to initial instruction on labor protection: a sample list of topics common to many organizations that need to be covered during instruction;

lists of persons who undergo this instruction or who may not undergo it; answers to typical questions that arise for decision-makers. The initial occupational safety training program covers safety provisions that an employee or student will constantly encounter.

This instruction is carried out after the introductory briefing, before the immediate start of the activity that the instructee will be engaged in. It is carried out with subordinates one at a time or with a group that will be engaged in the same type of activity.

Sample

Below is a sample training program on labor safety in the workplace, established in 2021 by GOST 12.0.004-2015:

| The initial training program at the workplace, as a rule, should include the following questions: 1. General information about the employee’s working conditions: the technological process, equipment and production environment at the employee’s workplace, the nature of his work process (tension and severity): • general familiarization information about the technological process and products manufactured by the division; • general familiarity with the equipment located at the workplace, in the work area and within the territory and premises controlled by the department; • dangerous and harmful production factors present in the workplace and the risks of their impact on the human body; • collective protective equipment installed on the equipment (safety, braking devices and fences, blocking systems, alarms, etc.); • purpose, design and rules for using personal protective equipment (PPE) required in the workplace; • requirements for the safe organization and maintenance of a clean and tidy workplace; • safety requirements for operation and maintenance (repair) of equipment located in the workplace; • safety requirements for the prevention of electrical injuries. 2. The procedure for preparing for work: • requirements for workwear, safety footwear and personal protective equipment; • checking the serviceability of equipment, starting devices, tools, devices, interlocks, grounding and other protective equipment; • safe techniques and methods when performing work. 3. Scheme of safe movement of an employee throughout the territory of a unit or organization: • passages provided for movement; • emergency exits, restricted areas; • intra-shop transport and lifting equipment, locations and safety requirements when carrying out lifting operations. 4. Emergency situations that may arise in the workplace: • typical causes of accidents, explosions, fires, cases of industrial injuries and acute poisoning; • employee actions in the event of an emergency, industrial injury, acute poisoning; • locations of emergency protection and fire extinguishing equipment, rules for their use; • location of first aid equipment for the victim, first aid kits, rules for their use; • location of telephone communications, telephone numbers; • actions of an employee in the event of a dangerous situation that threatens the life and health of others, and in the event of an accident at work; • the procedure for the employee to report to representatives of the employer about an accident or acute poisoning that has occurred to him. 5. Familiarization with all instructions on the workplace and labor protection by profession (in accordance with the list of professions developed by the employer for each workplace, indicating the numbers of instructions required for instruction). |

Also see “Sample of a standard induction program for occupational safety and health.”

Read also

07.09.2017

For whom is initial training on labor protection required?

Primary training on labor protection is necessary for workers:

• large, medium and small companies of all areas of activity, educational, trade institutions, hospitals, offices of companies and firms; • employed by individual entrepreneurs who use hired labor; • working remotely, if the employer provides them with equipment or machinery or recommends its use to perform specific work; • working from home using equipment or materials provided by the employer;

as well as pupils and students:

• who will begin educational, production, and any other practical activities; • before performing each practical task that is new to them during laboratory and practical classes.

Initial briefings on labor protection, samples of which are kept by those responsible for instructing subordinate employees, are mandatory for:

• workers who move to a new place; • employees who have recently been employed and have undergone induction training; • workers who will work in additional professions (for example, a conveyor operator, if necessary, will replace a repairman). At the same time, instruction alone is not enough - appropriate professional training must be carried out; • seconded, temporarily employed, seasonal workers; • employees of contractors and subcontractors who will perform work simultaneously with the main personnel of the customer or work in areas temporarily transferred to their disposal.

This instruction is read to workers by their direct supervisor. Before this, he must undergo full training in all occupational safety issues raised during the briefing and have a valid occupational safety certificate. This obligation is fixed by order.

Who conducts initial training at the workplace?

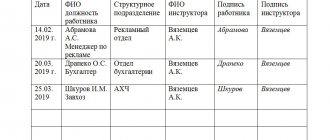

Initial briefing at the workplace is carried out by the head of the department or the immediate supervisor (producer) of the work (foreman, foreman, teacher, etc.), who has undergone training in labor protection in the prescribed manner and tested knowledge of labor protection requirements as a labor protection instructor.

Initial on-the-job training for personnel of contracting (subcontracting) organizations performing work on territories and facilities controlled by the enterprise that organizes the training is carried out by the immediate supervisor (producer) of the work - a representative of the contracting (subcontracting) organization together with the head of the department or with the person responsible for the contract work. at workplaces (in the work area, territory) of this unit. The procedure for the safe performance of these works, including the procedure for instructing workers, can be drawn up in a separate document, which is an integral part of the contract for the performance of contract (subcontract) work (rendering services).

Who is provided with initial training at the workplace?

In accordance with clause 8.7 of GOST 12.0.004-2015, initial training at the workplace is carried out before the start of independent work of the instructed persons:

- with all newly hired persons, including for short-term, seasonal and other temporary work, in their free time from the main job (part-time workers), as well as at home (homeworkers) using materials, tools and mechanisms provided by the employer or purchased them at their own expense;

- with workers transferred in accordance with the established procedure from another department, or with workers who are entrusted with performing work that is new to them;

- with personnel from other organizations sent to work for the training organizer;

- with the personnel of contractors (subcontractors) performing work on the territory and facilities controlled by the training organizer;

- with students of educational institutions of appropriate levels undergoing practical training (practical classes), and with other persons participating in the production activities of the enterprise that organizes the training.

Initial training program on labor protection

Initial instruction on labor protection, a sample of which must be kept by the management of the company's division, is organized exclusively at the workplace. Appendix 5 to GOST 12.0.004-90 offers a list of the main topics that are recommended to be covered during this instruction. It includes:

1. The equipment used, its features, methods of ensuring safety.

2. Overview information about production technology and processes carried out in the department.

3. Circumstances of injuries, accidents that occurred in similar workplaces, their causes, ways to prevent them.

4. Hazards that may be encountered during work: hazardous areas of equipment, possible malfunctions, negative environmental influences, what a worker should do when something goes wrong.

5. Fire and electrical safety, evacuation schemes.

6. Sequence of preparation for work and its completion.

7. Safety rules during the execution of work, requirements for the quality of their execution.

8. Safety rules for various types of work, including dangerous ones, and transportation of goods.

9. Rules for safe behavior in the workplace and tool care.

10. Information about fire extinguishing equipment, electrical protection, alarm systems, personal protective equipment.

11. Tasks that are solved at this workplace, associated features, requirements, factors with a negative effect on the body.

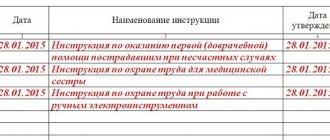

The initial training program on labor protection includes the requirements of occupational safety instructions, internal regulations, and other local regulatory documentation, the requirements of which are mandatory for the employee to comply with. It is developed by the head of the unit, who has undergone occupational safety training appropriate to his position. Next, it needs to be agreed upon by the OT service and approved by the head of the organization.

When conducting initial instruction on labor protection, you cannot simply read the instructions one by one. The briefing program should be worked out in advance, ensuring that the information is understood as best as possible. Diagrams, posters, and training materials will help improve your understanding of the material. At the same time, it is necessary to demonstrate safe working methods.

According to which local act is initial training carried out at the workplace?

In accordance with clause 8.7 of GOST 12.0.004-2015, initial training at the workplace is carried out by:

- or according to programs (Appendix B, program B.2) developed and approved by the training organizer in the prescribed manner in accordance with the requirements of legislative and other regulatory legal acts on labor protection, local regulations, instructions on labor protection in the workplace and on safe implementation works, other technical and operational documentation necessary to ensure safety,

- or directly according to instructions on labor protection and (or) safe performance of work at a given workplace,

- according to other local regulations and documents necessary for instruction.

According to the new GOST, initial training in the workplace can be carried out according to an approved program of initial training in the workplace or according to instructions on labor protection in the workplace, and this mechanism must be enshrined in the local regulatory act of the organization.

I believe that it is important to maintain continuity with GOST 12.0.004-90 and carry out initial training at the workplace according to the approved Program for Initial Training at the Workplace, in which we indicate which labor safety instructions we provide for the given position of the employee.