Individual protection means

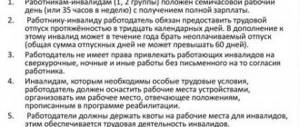

(

PPE ), English. Personal protective equipment

(PPE) - specially designed devices, devices, drugs, etc.

which are intended to protect humans from harmful external factors, prevent or reduce exposure to harmful and dangerous production factors, as well as to protect against pollution. They are used in cases where work safety cannot be ensured by the design of equipment, the organization of production processes, architectural and planning solutions and collective protective equipment. As a rule, personal protective equipment is used during a person’s work activity, when it is necessary to ensure protection of the skin of the body and respiratory organs from exposure to harmful toxic and polluting substances. Personal protective equipment is divided into respiratory protection equipment RPP

) and skin protection equipment.

RPE includes gas masks, respirators, cotton-gauze bandages, skin protection means - protective suits , dermatological preparations (creams, lotions, etc.). The choice of protective equipment is made taking into account their purpose and protective properties, specific environmental conditions and the nature of the infection. For example: a civilian gas mask will not help in a smoky room, because... the oxygen level in the room will be low and other sources of oxygen are needed.

Classification of PPE

The classification of PPE in Russia is established by GOST 12.4.011-89, where, depending on the purpose, they are divided into 11 classes, which, in turn, depending on the design, are divided into types:

- Isolating

suits (pneumatic suits, waterproofing

suits , spacesuits) - Respiratory protection equipment

(gas masks, respirators, self-rescuers, pneumatic helmets, pneumatic masks, pneumatic jackets) - Special protective

clothing (sheep coats,

coats , short coats, short fur coats, capes , raincoats , half-coats, gowns suits , jackets, shirts , trousers , shorts , overalls , bib overalls, vests , dresses , skirts , aprons , shoulder pads) - Foot protection

(

boots , boots with an extended shaft, boots with a short shaft, ankle boots , boots , low shoes, shoes, shoe , galoshes , boots , slippers ( sandals ), boots , boots , shin guards, over the knee boots, knee pads, foot wraps, - Hand protection

(mittens, gloves

, semi -gloves , palm pads, wrist pads, sleeve pads, elbow pads) - Head protection

(

hard hats , helmets, balaclavas, caps berets , hats, caps, headscarves , mosquito nets) - Eye protection

(

goggles ) - Face protection

(

face shields - Hearing protection

(anti-noise helmets, anti-noise earplugs, anti-noise headphones, - Fall protection equipment and other safety equipment

(safety belts, cables, hand grips, manipulators, knee pads, elbow pads, shoulder pads) - Dermatological protective products

(protective creams, skin cleansers, reparative agents) - Comprehensive protective equipment

What is PPE: decoding and definition

PPE stands for “personal protective equipment.” These are means used by the employee to prevent or reduce exposure to harmful and dangerous production factors, as well as to protect against pollution. They are used in cases where work safety cannot be ensured in any other way (for example, by the design of equipment, organization of production processes, architectural and planning solutions and collective protective equipment).

PPE may include special clothing, special footwear, isolation suits, respiratory protection, hand protection, head protection, face protection, hearing protection, eye protection, and various safety devices.

Working clothes and personal protective equipment

Overalls are one part of all personal protective equipment. Workwear , like other personal protective equipment , is in demand and is applicable in many areas of production. Such professional activities include the activities of builders, installers, chemical production, heavy engineering, pharmaceutical production, metallurgy, food industry and others.

The main function of workwear is to ensure a sufficient level of labor safety, including protection from various mechanical damage. However, in addition to the main function, workwear also performs several additional ones. These include the advertising or marketing function, which is important for the operation of an enterprise. Workwear plays an important role in the prosperity of an enterprise and a certain psychological mood, in uniting the team and increasing labor productivity. That is why work shoes and work suits , as well as other types of workwear, should be selected not only based on practicality and safety, but also from the point of view of branding. As a rule, the company logo and often a slogan are applied to the workwear. For example, in the city of Lipetsk, in an auto parts store, the managers have a T-shirt that says “I know everything, ask me”

Workwear is clothing , which is designed to protect the worker from the negative effects of the production process or the environment. Workwear includes a work suit and special shoes , work gloves and a respirator , gloves or hats . Overalls must provide a certain level of protection, for example, be water-repellent, heat-resistant, hygienic (for medical staff), antistatic, etc.

How to use

The effectiveness of using protective equipment at an enterprise depends on the correctness of their choice. The selection of necessary elements should be carried out taking into account the type of activity and the impact of hazardous environmental factors on workers. The employee must understand what personal protective equipment is and use these items correctly.

Protective clothing

Elements for protecting human skin from harmful influences are suits and overalls. If necessary, these collective protective equipment are equipped with gloves, masks, and special shoes. Overalls can be insulating or filtering. Kits of the first type are made of airtight materials. They provide reliable protection in conditions of radiation and bacteriological contamination. These include a general military protective kit, which consists of a rubberized raincoat, boots, and gloves.

Filter clothing is made from special materials impregnated with chemicals. The fabric does not allow harmful vapors to pass through, while remaining breathable. Individual anti-chemical protective clothing sets are used for work in areas of disasters, accidents, and hazardous industries. Robes and jackets made from ordinary fabrics are simple means of protecting human skin from biological agents. They are designed for work in production and protect against dirt, water, and dust.

To protect feet from water and harmful solutions, special work shoes are provided. These can be rubber boots with additional protective elements (reinforced toe). Protect your hands with cotton or rubber gloves. All employees are required to use the facilities provided to them. At the beginning of the shift, the foreman must check the availability of protective kits and their correct operation. Items unsuitable for work are replaced with new ones as they wear out.

Mounting belt

For installation work, special personal protective equipment has been developed to prevent falls from height. This device can be made in the form of a safety belt or slings with carabiners. They come in strap and tape types. These elements are used by rescue services, installers, and industrial climbers. The slings can be equipped with shock absorbers that provide a soft touch to the surface without jerking. The belt is worn over the work overalls and secured with clips.

Respiratory and skin protection

The most reliable element that protects a person’s face and respiratory tract from toxic substances is a gas mask. It works on the principle of filtration or isolation from external influences. Filtering gas masks are equipped with an air purification system. This device is the main element among personal respiratory protection equipment. Gas masks are divided into civil and industrial. They have different purposes.

Modern civilian gas masks, which include filter masks, are used for the defense of the population. If you detect signs of bacteriological infection, you should put a helmet-mask on your head. When put on correctly, the gas mask should fit snugly to the face, and the glasses should be exactly in front of the eyes. These funds are issued to the population in special bags. There are modifications for children that protect the child from harmful environmental emissions. Filter systems are used for this.

Insulating gas masks are designed for work in areas affected by radioactive substances (nuclear accidents, catastrophes). They are used in cases where filter elements cannot provide the required level of protection. Industrial gas masks block the entry of contaminated air into the human body. The protection element is equipped with a breathing bag, a regenerative cartridge and a bag. Gas masks are stored in accordance with the instructions of sanitary inspection authorities.

- Eye pressure - norm and measurement. Symptoms and treatment of high eye pressure at home

- Potato casserole in the oven: recipes

- How to celebrate a birthday in an original way

Respirators are used in hazardous industries to protect the respiratory tract of workers from harmful impurities. This product is a half mask with filter fabric. When using a respirator, you must ensure that it fits tightly to your head to prevent contaminated air from entering your lungs. Using available materials, workers can make their own anti-dust gauze bandage.

Organs of vision

Special glasses are used to protect eyes in production. Glass can be shockproof, metallized, equipped with light filters. The first type of glasses is used when working with hard materials: metal, wood, stone. They provide eye protection from chips, sparks, and industrial dust. Glasses with filters protect vision from ultraviolet and infrared waves. Personal eye protection can be presented in the form of:

- head shields;

- masks;

- helmets

Head PPE

In factories and construction enterprises, the workwear set includes helmets and special headgear. The purpose of personal protective equipment for the head is to protect a person from mechanical injury. Additionally, they protect the hair and neck from dirt and dust. Helmets are used during installation work in industrial production. Additionally, they can be equipped with balaclavas, goggles, and elements to protect the neck.

Types of workwear

At the moment, there are a sufficient number of types of workwear. These include not only work suits , but also clothing for service sector workers, uniforms for medical staff, corporate accounting clothing, workwear for pharmacy and pharmacy store workers, robes for judges and clergy. The presence of simply a huge variety of workwear aroused genuine interest in it among modern designers, company managers and directors, who have already “tried it on”, albeit in absentia, to their employees. The purchase of corporate workwear has even become an element of a certain prestige for the company and a way to advance in the thematic market.

Basic requirements for workwear

Sewing any model of workwear begins with the selection of fabrics, determining the model, taking into account all the specifics of the work, as well as adapting the work suit to the general style of the enterprise or company. Additional processing includes applying the company's symbols or brand to a work suit , work shoes or protective equipment.

The following requirements apply to high-quality workwear:

- The quality, durability and strength of the materials from which the work suit or shoes . Any workwear should be reliable to wear: ideally, a suit should last 2-3 years and maintain a fairly decent appearance. For clothing that is used in a complex manufacturing process, tear-resistant seam threads should be used, preferably heat-resistant or reinforced threads.

- Climate compliance. The entire set of work clothing must comply with climate conditions and the season ( winter workwear , summer workwear , demi-season workwear ).

- Full compliance with the professional field and specifics of the work. Workwear should be ergonomic and comfortable to wear . For each professional application, the cut of the suit, decoration and number of pockets, fastener options, etc. are taken into account.

- Repairability and reliability. The work suit must recover well and be resistant to shrinkage or abrasion.

- Quite a high degree of hygiene. A work suit must be breathable and hygroscopic. Comfort during work and the health of the employee depend on this.

- Aesthetic appearance of workwear. Modern workers have a keen sense of the style and beauty of a work suit. Therefore, both work shoes and a suit should complement each other, harmonize in color, and be visually attractive. In this case, we are talking not only about the office version of business clothing, but also about overalls for machine operators or welders, as well as specialists in repair and construction work.

Modern materials are able to meet the requirements of workwear!

PPE quality control

All PPE received by enterprises is issued to employees after inspection by a commission (the composition is approved by the employer). The main task of the commission is to prevent the use of PPE :

- not corresponding to the application;

- without a certificate of conformity;

- not meeting working conditions;

- not corresponding to the markings for protective properties;

- not meeting the requirements of regulatory and technical documentation (GOST, TU, TO).

PPE is checked as it arrives at the warehouse, but no later than 10 days from the date of receipt. For inspection, the enterprise must be allocated a room with a work table and measuring instruments, normative and technical documentation, catalogs, reference books, etc. Each batch of PPE newly received at the enterprise must be subjected to an external inspection and checked for compliance with the declared range of models, sizes, heights, color, generic sign, purpose. Large batches are subject to random control, but not less than 10% of the total volume. The main feature confirming compliance of PPE with standards is a certificate of conformity and the corresponding sign, marked in accordance with GOST 50460-92. Based on the results of the PPE inspection, a report in the established form is drawn up. In cases of non-compliance, PPE must be returned to the supplier.

Responsibilities of the employer to provide workers with personal protective equipment

Labor protection for workers implies free provision of workers with special shoes, clothing, and additional protective equipment. All necessary elements are issued in accordance with the standards and deadlines in force at a particular production site. Workers should not be allowed to enter the workplace without personal protective equipment. The administration is required to regularly conduct safety training so that employees know what PPE is. It is necessary to arrange training on the correct use of products.

Protective kits are stored in dry rooms with normal humidity levels. After use, clothing, shoes, and masks are cleaned, repaired, and disinfected. The employer must ensure timely processing of special clothing. The administration is obliged to buy new kits on time at the best price and replace those that have become unusable. When an employee leaves, the kit he receives is returned to the warehouse. Duty special equipment used by a group of workers must be kept in a separate warehouse and issued by the foreman for the duration of the work.

Issue norms

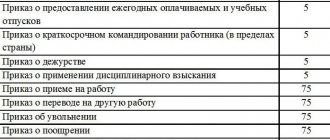

At each enterprise, the receipt of protective equipment and sets of additional elements is carried out under the control of the administration. The number of elements and terms of use are determined according to the issuance standards. Examples can be seen in this table:

| Job title | Name of special equipment | Issue rate per year, pieces (sets) |

| fitter | Protective suit | 1 |

| Polymer coated gloves | 12 pairs | |

| Gloves with dotted surface | Before wear | |

| Glasses | Before wear | |

| Loader driver | Suit for protection against general pollution | 1 |

| Rubber boots | 1 | |

| Polymer coated gloves | 6 pairs | |

| Respirator | Before wear | |

| Galvanizer | Suit protecting against acid solutions | 1 |

| Robe, protective trousers | 1 kit | |

| Apron with polymer bib | 2 | |

| Rubber boots with protective elements | 1 | |

| Polymer coated gloves | 6 | |

| Rubber gloves | 6 | |

| Safety glasses | Before wear |

Rules for providing PPE at enterprises

The main legal act defining the procedure for providing workers with PPE is the Rules for providing workers with special clothing, special shoes and other personal protective equipment

, approved by Decree of the Ministry of Labor and Social Development of Russia dated December 18, 1998 No. 51. The rules provide for the provision of PPE according to Standard Standards, regardless of which sector of the economy the production belongs to, and also regardless of the form of ownership of organizations.

In some cases, in accordance with the characteristics of production, the employer may, in agreement with the state labor safety inspector and the relevant trade union body or other representative body authorized by the employees, replace one type of personal protective equipment provided for by the Standard Industry Standards with another that provides complete protection from dangerous and harmful production conditions. factors: overall can be replaced with a cotton suit or robe and vice versa, suit with overalls with a shirt (blouse) or a sundress with a blouse and vice versa, a can be replaced with a cotton suit with fire-retardant or acid-proof impregnation and vice versa, a suit can be replaced with a cotton suit with fire-retardant impregnation or water-repellent impregnation and vice versa, boots ( low boots ) - with rubber boots and vice versa, boots ( low boots ) - with tarpaulin boots and vice versa, boots - with tarpaulin boots and vice versa, a rubberized apron - with an apron made of polymer materials and vice versa, mittens - with gloves and vice versa , gloves - with gloves made of polymeric materials and vice versa, vachegi - with heat-resistant gloves made of synthetic material and vice versa, plastic oversleeves - with oversleeves made of polymeric materials and vice versa. In cases where such personal protective equipment as vest , a safety belt, dielectric galoshes and gloves , a dielectric rubber mat safety glasses and shields , a respirator , a gas mask, a protective helmet , a helmet, shoulder pads , elbow pads, self-rescuers, antiphons, plugs, noise-proof helmets, light filters, vibration-proof gloves and others are not specified in the Standard Industry Standards, the basis for the issuance of which is the certification of workplaces depending on the nature of the work performed with a wear period - until worn out or as duty workers and can be included in collective agreements and agreements. The employer is obliged to replace or repair PPE that has become unusable before the end of the wear for reasons beyond the employee’s control.

Storage of PPE

The obligation to properly store and care for personal protective equipment is mandatory for the employer and clause 30 of Order No. 290n of the Ministry of Health and Social Development.

And many organizations approach this procedure differently; large ones, as a rule, have their own laundries, while smaller ones enter into an agreement to provide these services. I have had both experiences in my practice, so I will try to share them in as much detail as possible.

In large enterprises, all responsibilities are clearly distributed among employees; storage and care of PPE is no exception.

I leave you a link to download the order and simplify your work; you can adjust it depending on the conditions of your organization by adding details.

Employer's liability

If the employer does not comply with legal requirements, then he faces punishment in the form of an order and a fine under Part 1 of Art. 5.27.1 Code of Administrative Offenses of the Russian Federation, which is:

- for an official from 2000 to 5000 rubles;

- for legal from 50,000 to 80,000 rubles.

The fine is decent and you shouldn’t think that it’s easier to pay than to execute. Not this way! Pay and then you will have to do it anyway. It's better right away.

Where is PPE storage allowed?

The storage of personal protective equipment is detailed in SP 44.13330.2011 “Administrative and domestic buildings” and is given in the PPE passport or in the operating instructions, which are attached after purchase.

But there are also general basic storage requirements; the following conditions must be met:

- storage must be ensured in a dry room equipped with heating and ventilation;

- depending on the conditions of production activity, the premises are equipped with dryers;

- It is prohibited to store personal belongings and work clothes in one closet; for this purpose, two storage lockers are allocated;

- if protective clothing made of rubberized materials is used, it is necessary to organize darkening from direct sunlight at temperatures up to +20 C, away from heating devices and without contact with each other;

- there are similar requirements for personal respiratory protection equipment (RPPE), plus the absence of the possibility of mechanical damage during storage and high humidity;

- harnesses must be stored either hanging or unfolded on racks;

- PPE should not be stored near paint, varnish, oils, alkalis and other chemicals;

- changing rooms should be separate for men and women.

There are few requirements, but all of them must be observed for a longer period of use of workwear and safety footwear, and those employers who really want to ensure proper storage of PPE have a question: “Where is it allowed to store PPE?”

It is proposed to equip such places in production premises, but this is unacceptable, because clause 31 of Order No. 290n states that storage is possible only in specially designated areas (dressing rooms), with certain requirements and rules (SP 44.13330.2011).

This must be done because clause 27 of Order No. 290n employees do not have the right to take personal protective equipment out of the organization’s territory after the end of the working day.

And it’s worth paying attention to the pressing issue of storing winter PPE. If you rent it out to a warehouse for storage during the summer, then the period of use in this case continues to count and go.

Because clause 13 of Order No. 290n clearly states that the period of use is counted from the moment PPE is issued to the employee, because protective clothing gradually loses its protective properties during storage under any circumstances.

PPE repair

The employer is also responsible for repairs, and how can this be the responsibility of the employee if he does not have the right to take PPE outside the territory. Therefore, every malfunction and failure must be reported to the employer.

And there a decision is already made about the feasibility of writing it off or making repairs. If an organization independently carries out repairs, then, as a rule, there is a worker on staff to repair PPE in a room that is necessarily equipped with supply and exhaust ventilation.

Repair of PPE must be carried out on time in order to maintain maximum protective properties. For example, if PPE made from cotton or linen fabric is being repaired, then similar, clean and new fabric should be used for patches. Rubberized personal protective equipment is repaired using a polymer coating and special rubber glue.

Cleaning and washing PPE

The painful question is “When should PPE be washed if workers constantly use it during working hours?”

There is only one solution: to issue two suits with double the wear period, but many employers “get out” in the following way: they issue the employee one new set and a second used one. So the employee always has a replacement, and if one of them becomes unusable, he will have something to replace him with.

Although there are organizations where they don’t even issue one set, let alone the second. In this case, all responsibility lies with the employer, after a competently prepared memo on the need to purchase, store and care for PPE.

Washing is also a delicate matter, and you can set your own frequency if this point is not regulated in the Interindustry Rules.

For example, for organizations related to the water supply and sewerage sector, it is necessary to wash PPE for heavy contamination once every 6 days and for minor contamination once every 10 days.

But of course, if there is a need to reduce the frequency, you can, but you can’t increase it.

And as I said earlier, you can do the laundry either yourself or enter into an agreement. I provided the director with the costs under the contract and provided calculations for the purchase of a washing machine and dryer, the payback period, and the employer agreed to purchase and create a mini-laundry in the organization.

If your management is also ready to follow the same path, then it is necessary to organize work in accordance with POT R M-013-2000 Interindustry rules for labor protection during dry cleaning and washing. From them you can find out what the requirements for the room, process and equipment are.

We missed an important point regarding the issuance of clean PPE; in terms of receiving dirty and receiving clean, they should not overlap. An order and a fine were issued, the reprimand was removed, and the regulations were read more carefully in the future.

Efficiency

Based on accumulated experience, Western experts in industrial hygiene and occupational diseases believe that in the system of protection against harmful production factors, the use of PPE is the latest and most unreliable method, which should be used only when the use of more reliable methods of protection (changes in technology, automation of harmful production facilities, equipment sealing, effective ventilation, air showers, remote control, etc.) is impossible; or possible - but does not reduce harmful exposure to a safe level.

Law 426-FZ allows reducing the hazard classes of working conditions while providing workers with PPE (and maintaining exposure to harmful factors at the same level - without any improvement in working conditions); and the Social Insurance Fund compensates the employer for the purchase of PPE .