As you know, every employee at any enterprise must have his own job description. An occupational safety specialist is no exception to this rule. He, like other employees, has a number of responsibilities and functions that undoubtedly require detailed presentation on paper. Let's look at what specific features distinguish this position, what should be taken into account when drawing up job descriptions for managers and specialists working in the field of ensuring the safety of the organization's employees.

What is a Health and Safety Engineer?

Whatever the company does, the legislation of our country requires its owners to take care to ensure the safety of workers for the benefit of its workers. It is understood that when the number of personnel exceeds 50 people, a special unit is included in the staffing table, most often called a labor protection engineer, for which an individual is hired or which is combined with the main job of one of the people already hired at the company. The greater the number of employees and workers at the enterprise, the larger the service responsible for labor safety becomes.

A safety (occupational health) engineer is a technical specialist involved in debugging and monitoring the operation of the occupational safety system at an enterprise and the prevention of industrial accidents. Most often, he reports directly to the head of the department, chief engineer or director of the organization (depending on its structure and size).

Requirements for applicants for the position

A typical job description for a specialist, labor protection engineer, having any category, as a rule, contains the following professional characteristics that an employee must have.

A specialist hired for a category I position must have a higher education with a technical profile and work experience as an occupational safety engineer of category II. An employee applying for category II must also have a higher technical education and work experience as an occupational safety (safety) engineer or another engineering and technical employee position with a similar level of training required.

What does a typical job description for a health and safety specialist without a category tell us? For this position, it is recommended to hire a person with a higher engineering and technical education who does not have work experience, or a specialist with a diploma of qualification from an educational institution of secondary vocational technical education and work experience in this qualification.

What to follow in your work?

What other item does the job description necessarily include? An occupational safety specialist, like all other specialists, when performing his functions, is guided by certain documents, namely:

1. Methodological materials and recommendations in the field of occupational safety and health, affecting the scope of the organization’s work and general issues of ensuring worker safety.

2. Charter of the enterprise.

3. Laws and regulations relating to occupational safety and health.

4. Internal local regulations, in particular the internal labor regulations of the company.

5. Directions, orders from the manager.

6. The actual information contained in the job description of a labor protection and safety engineer.

JOB DESCRIPTION

health and safety inspector

1. General Provisions

1.1. This job description defines the functional, job responsibilities, rights and responsibilities of the occupational health and safety inspector of the Methodological Technologies unit (hereinafter referred to as the Occupational Health and Safety Inspector) of the Federal State Autonomous Educational Institution of Higher Professional Education "National Research Nuclear University "MEPhI" (NRNU MEPhI) ( hereinafter Institution).

1.2. A person who meets the following education and training requirements is appointed to the position of occupational health and safety inspector:

- Additional professional programs - advanced training programs, professional retraining programs;

- Higher education - bachelor's degree;

with practical work experience:

- At least five years in NPP engineering and technical positions;

Special conditions for admission to work of a labor protection and safety inspector:

- Permission from Rostechnadzor to carry out work in the field of atomic energy use;

- Preparation for a position, passing a knowledge test (availability of a qualification certificate), permission to work independently;

- Passing mandatory preliminary (upon employment) and periodic medical examinations (examinations), as well as extraordinary medical examinations (examinations) in the manner established by the legislation of the Russian Federation;

1.3. The health and safety inspector must know:

- Safety standards and regulations in nuclear energy;

- Operating instructions for AC equipment;

- Norms and rules of environmental safety;

- Directions, orders in the area of activity;

- Technical justification for nuclear power plant safety;

- Basic rules for ensuring the operation of nuclear power plants;

- State and industry standards in the area of activity;

- NPP safety report;

- Technological diagrams of equipment and systems;

- AU Administrative Instructions;

- Radiation safety norms and rules;

- Legislation of the Russian Federation in the field of environmental protection;

- Regulations on the peculiarities of investigation of industrial accidents in certain industries and organizations;

- Nuclear safety standards and regulations;

- NPP quality assurance programs;

- Sanitary norms and rules;

- Instructions for eliminating accidents at nuclear power plants;

- Technical justification for the safety of the reactor installation;

- Guidelines for analyzing the causes of violations;

- Labor legislation of the Russian Federation;

- Legislation of the Russian Federation in the field of nuclear energy use and safety in the area of activity;

- Technical characteristics of the AC equipment;

- Building regulations;

- Occupational safety requirements;

- Safety Culture Principles;

- Designs of main equipment of the NPP;

- Industrial safety standards and regulations;

- Occupational safety management system;

- Fire safety rules;

- Operating conditions for NPP equipment;

- Internal regulatory documents and reporting forms in the area of activity;

- Radiation safety norms and rules;

- Labor legislation of the Russian Federation;

- Requirements for equipping workers' workplaces;

- NPP quality assurance programs;

- Fire safety rules;

- Reporting forms for the area of activity;

- Legislation of the Russian Federation in the field of nuclear energy use and safety in the area of activity;

- Nuclear safety standards and regulations;

- Reviews on violations in the operation of domestic and foreign nuclear power plants;

- Operating conditions for NPP equipment;

- Safety standards and regulations in nuclear energy;

- Experience in operating domestic and foreign NPPs;

- Norms and rules of environmental safety;

- State and industry standards in the area of activity;

- Sanitary norms and rules;

- Legislation of the Russian Federation in the field of environmental protection;

- AU Administrative Instructions;

- Occupational safety management system;

- Industrial safety standards and regulations;

- Ergonomics of workers' workplaces;

- Occupational safety requirements;

- Basic rules for ensuring the operation of nuclear power plants;

- Building regulations;

- Safety Culture Principles;

- Labor legislation of the Russian Federation;

- Internal regulatory documents and reporting forms in the area of activity;

- Safety standards and regulations in nuclear energy;

- Building regulations;

- Occupational safety requirements;

- Legislation of the Russian Federation in the field of environmental protection;

- Nuclear safety standards and regulations;

- Fire safety rules;

- Sanitary norms and rules;

- Legislation of the Russian Federation in the field of nuclear energy use and safety in the area of activity;

- Radiation safety norms and rules;

- Safety Culture Principles;

- Industrial safety standards and regulations;

- AU Administrative Instructions;

- Occupational safety management system;

- Basic rules for ensuring the operation of nuclear power plants;

- State and industry standards in the area of activity;

- Directions, orders in the area of activity;

- NPP quality assurance programs;

- Norms and rules of environmental safety;

- Designs of main equipment of the NPP;

- AU Administrative Instructions;

- Internal regulatory documents and reporting forms in the area of activity;

- Sanitary norms and rules;

- Basic rules for ensuring the operation of nuclear power plants;

- NPP safety report;

- Technological diagrams of equipment and systems;

- Occupational safety requirements;

- Directions, orders in the area of activity;

- Occupational safety management system;

- Legislation of the Russian Federation in the field of nuclear energy use and safety in the area of activity;

- Radiation safety norms and rules;

- State and industry standards in the area of activity;

- Building regulations;

- Technical characteristics of the AC equipment;

- Norms and rules of environmental safety;

- Nuclear safety standards and regulations;

- Labor legislation of the Russian Federation;

- Operating instructions for AC equipment;

- Operating conditions for NPP equipment;

- NPP quality assurance programs;

- Safety standards and regulations in nuclear energy;

- Technical justification for the safety of the reactor installation;

- Technical justification for nuclear power plant safety;

- Industrial safety standards and regulations;

- Legislation of the Russian Federation in the field of environmental protection;

- Safety Culture Principles;

- Fire safety rules;

- Occupational safety requirements;

- Technical justification for the safety of the reactor installation;

- NPP safety report;

- AU Administrative Instructions;

- Nuclear safety standards and regulations;

- Safety Culture Principles;

- Technical characteristics of the AC equipment;

- Operating instructions for AC equipment;

- Norms and rules of environmental safety;

- Legislation of the Russian Federation in the field of nuclear energy use and safety in the area of activity;

- Technological diagrams of equipment and systems;

- Radiation safety norms and rules;

- Safety standards and regulations in nuclear energy;

- Directions, orders in the area of activity;

- NPP quality assurance programs;

- Building regulations;

- Labor legislation of the Russian Federation;

- Internal regulatory documents and reporting forms in the area of activity;

- Fire safety rules;

- Technical justification for nuclear power plant safety;

- Occupational safety management system;

- Industrial safety standards and regulations;

- Basic rules for ensuring the operation of nuclear power plants;

- Equipment operating conditions;

- Sanitary norms and rules;

- Designs of main equipment of the NPP;

- State and industry standards in the area of activity;

- Legislation of the Russian Federation in the field of environmental protection;

1.4. A health and safety inspector must be able to:

- Prepare prescribed reports;

- Apply standards, methods and instructions when conducting inspections;

- Use office equipment and software products;

- Collect and record information based on the results of inspections;

- Use technical documentation to perform assigned tasks;

- Identify inconsistencies between these checks and regulatory values and deviations from them;

- Document the results of the work performed;

- Analyze the implementation of corrective measures;

- Apply standards, methods and instructions when carrying out work;

- Prepare information to promote the prevention of violations;

- Use regulatory and technical documentation to perform assigned tasks;

- Collect and record the necessary information;

- Prepare prescribed reports;

- Use communication methods;

- Analyze and evaluate information on monitoring the activities of departments;

- Prepare prescribed reports;

- Identify inconsistencies between information data and regulatory values, deviations from them;

- Collect and record the necessary information to control the activities of departments;

- Use regulatory and technical documentation to perform assigned tasks;

- Apply standards, methods and instructions when carrying out work;

- Use regulatory and technical documentation to perform assigned tasks;

- Conduct a survey of plant employees;

- Use communication methods;

- Identify deviations and inconsistencies based on the results of monitoring compliance with regulatory and production documentation requirements;

- Use office equipment and software products;

- Prepare established reporting, including using information systems;

- Document the checks performed;

- Use regulatory and technical documentation to perform assigned tasks;

- Identify inconsistencies between measurement data of parameters and the results of inspections, testing, testing of equipment with regulated values, deviations from them;

- Compare parameters with regulated values;

- Study and use best practices in the area of activity;

- Collect and record the necessary information;

- Apply standards, methods and instructions when conducting inspections;

1.5. The labor protection and safety inspector is appointed and dismissed by order of the Vice-Rector for Educational and Methodological Work of the Institution in accordance with the current legislation of the Russian Federation.

1.6. The labor protection and safety inspector reports to the vice-rector for educational and methodological work of the Institution and the head of the department “Methodological technologies”

2. Labor functions

- 2.1. Monitoring the implementation of corrective measures based on the results of the investigation of violations in the operation of the plant.

- 2.2. Carrying out methodological and preventive work to prevent disruptions in the operation of nuclear power plants.

- 2.3. Monitoring the activities of departments for organizing work with personnel.

- 2.4. Monitoring compliance with regulatory and production documentation requirements.

- 2.5. Monitoring the state of nuclear, radiation, environmental, fire, technical, industrial safety, labor protection, operational safety of industrial buildings and structures of nuclear power plants and when handling nuclear materials and radioactive substances.

3. Job responsibilities

- 3.1. Assessment of the condition of equipment and NPP systems.

- 3.2. Conducting analysis, identifying trends and developing proposals to improve the reliable and safe operation of nuclear power plants.

- 3.3. Documentation of completed work.

- 3.4. Conducting an assessment of the nature and scale of disturbances in the operation of the plant.

- 3.5. Conducting an analysis of the operation of NPP equipment.

- 3.6. Conducting assessment and analysis of information based on control results.

- 3.7. Analysis of the effectiveness of corrective measures based on the results of the investigation of violations in the operation of the plant.

- 3.8. Work on the commission to investigate violations and deviations in the operation of nuclear power plants in accordance with official authority.

- 3.9. Development of proposals for the prevention of disruptions in the operation of nuclear power plants based on an analysis of activities and identified trends.

- 3.10. Conducting an analysis of the operation of NPP equipment.

- 3.11. Supervision of compliance with the norms and rules for the maintenance of hermetically sealed enclosures (FE) and their elements, industrial buildings and structures and the correct maintenance of the structural elements of FE, buildings and structures by NPP workshop workers.

- 3.12. Conducting targeted audits in the area of activity.

- 3.13. Testing employees' knowledge of the requirements of rules, regulations and instructions at the workplace.

- 3.14. Development of internal guidelines, rules and measures to ensure operation and repair, instructions for workshops and departments for the operation of industrial buildings, structures, hermetic fences and their elements.

- 3.15. Providing methodological assistance to NPP divisions in planning and organizing repair work of civil defense and their elements, industrial buildings and structures by repair organizations and production shops.

- 3.16. Conducting an analysis of the actual condition of buildings and structures, identifying emergency or pre-emergency structures and structures, operating deficiencies and developing measures for the timely elimination of identified deficiencies.

- 3.17. Preparation of information to promote the prevention of disturbances in the operation of nuclear power plants.

- 3.18. Verification of compliance with approved work schedules at the plant.

- 3.19. Conducting an analysis of the causes of violations and deviations in the operation of the plant.

- 3.20. Monitoring the implementation of activities based on the results of inspections.

- 3.21. Development of corrective measures to prevent disruptions in NPP operation.

- 3.22. Registration of work results.

- 3.23. Conducting walk-throughs and inspections of workers’ workplaces, equipment, territories, premises, buildings and structures of nuclear power plants.

- 3.24. Supervising the production activities of departments.

- 3.25. Conducting occupational safety and health days.

- 3.26. Methodological management of the activities of NPP production divisions on issues of ensuring NPP safety.

- 3.27. Testing employees' knowledge of the requirements of rules, regulations and instructions at the workplace.

- 3.28. Conducting occupational safety and health days.

- 3.29. Conducting targeted audits of the activities of departments for organizing work with personnel.

- 3.30. Control of licensing activities at nuclear power plants.

- 3.31. Verification of compliance by NPP divisions with approved personnel work schedules.

- 3.32. Carrying out work in accordance with official authority for training and testing knowledge (certification) of employees.

- 3.33. Registration of work results.

- 3.34. Monitoring the conduct of briefings, training and maintaining the qualifications of employees.

- 3.35. Monitoring the organization of work of commissions to test the knowledge of employees of NPP departments.

- 3.36. Preparation of instructions when identifying gross violations of the organization of work with personnel in departments.

- 3.37. Collection and recording of information based on the results of monitoring compliance with regulatory and production documentation requirements.

- 3.38. Control of licensing activities at nuclear power plants.

- 3.39. Monitoring compliance of operating modes of equipment and systems of power units and nuclear power plants with established requirements.

- 3.40. Registration of the results of the work performed.

- 3.41. Conducting walk-throughs and inspections of workers’ workplaces, equipment, territories, premises, buildings and structures of nuclear power plants.

- 3.42. Monitoring the maintenance of documentation at the workplaces of operational workers, the quality of execution of repair documentation and the maintenance of passports.

- 3.43. Documentation of work to monitor compliance with regulatory and production documentation requirements.

- 3.44. Monitoring the implementation of measures to comply with the requirements of state safety regulatory authorities.

- 3.45. Carrying out safety checks of the speakers.

- 3.46. Preparation of established reporting on performance results.

- 3.47. Periodic checks of workshop logs of technical inspections of sealed enclosures and their elements, building structures of buildings and structures for constant monitoring of the actual parameters of the operating environment in the production premises of the plant.

- 3.48. Carrying out safety checks when handling nuclear materials and radioactive substances.

- 3.49. Monitoring the sampling and testing procedure for NPP equipment.

- 3.50. Carrying out technical supervision of the technical condition, maintenance and maintenance of industrial buildings, structures, hermetic fences and their elements.

- 3.51. Conducting an analysis of the actual condition of buildings and structures, identifying emergency or pre-emergency structures and structures, operational deficiencies.

- 3.52. Carrying out safety checks of the speakers.

- 3.53. Preparation of established reporting on NPP safety issues.

- 3.54. Organization and maintenance of records of equipment and technical devices registered with supervisory authorities and organizations.

- 3.55. Data analysis of inspection results.

- 3.56. Carrying out technical examination of NPP equipment.

- 3.57. Analysis of the causes of equipment failures, emergency situations and industrial injuries.

- 3.58. Assessment of the condition of equipment and NPP systems.

- 3.59. Conducting walk-throughs and inspections of workers’ workplaces, equipment, territories, premises, buildings and structures of nuclear power plants.

- 3.60. Conducting analysis, identifying trends and developing proposals to improve the reliable and safe operation of equipment.

- 3.61. Registration of the results of work on NPP safety control.

Change job functions

4. Rights

The occupational health and safety inspector has the right to:

4.1. Request and receive the necessary information, as well as materials and documents related to the activities of the labor protection and safety inspector.

4.2. Improve your qualifications, undergo retraining (retraining).

4.3. Enter into relationships with departments of third-party institutions and organizations to resolve issues within the competence of the occupational health and safety inspector.

4.4. Take part in the discussion of issues included in his functional responsibilities.

4.5. Make suggestions and comments on how to improve activities in the assigned area of work.

4.6. Contact the relevant local government bodies or the court to resolve disputes arising during the performance of functional duties.

4.7. Use information materials and regulatory documents necessary to perform your job duties.

4.8. Pass certification in the prescribed manner.

5. Responsibility

The Health and Safety Inspector is responsible for:

5.1. Failure to perform (improper performance) of one’s functional duties.

5.2. Failure to comply with the orders and instructions of the Vice-Rector for the educational and methodological work of the Institution.

5.3. Inaccurate information about the status of fulfillment of assigned tasks and instructions, violation of deadlines for their execution.

5.4. Violation of internal labor regulations, fire safety and safety rules established in the Institution.

5.5. Causing material damage within the limits established by the current legislation of the Russian Federation.

5.6. Disclosure of information that has become known in connection with the performance of official duties.

For the above violations, the occupational health and safety inspector may be subject to disciplinary, material, administrative, civil and criminal liability in accordance with current legislation, depending on the severity of the offense.

This job description has been developed in accordance with the provisions (requirements) of the Labor Code of the Russian Federation dated December 30, 2001 No. 197 FZ (Labor Code of the Russian Federation) (with amendments and additions), the professional standard “Inspector in Nuclear Energy” approved by order of the Ministry of Labor and Social Protection Russian Federation dated December 24, 2015 No. 1127n and other regulations governing labor relations.

Share the job description on social networks:

What do you need to know?

As the standard job description of a labor protection engineer, a sample of which we are considering, shows, this specialist is expected to have the following knowledge:

- legislation in the field of labor protection;

- methods of organizing occupational health and safety activities, systems of labor protection standards;

- ways to become familiar with working conditions in the workplace;

- psychophysiological indicators of a person’s condition, acceptable when hiring him, depending on the severity of the work;

- main provisions of labor legislation;

- deadlines and procedures for submitting reports regarding occupational safety measures;

- means and rules for monitoring the compliance of the state of technology and equipment used at the enterprise with safety standards;

- features of the operation of equipment operating at the enterprise, and the main production processes carried out during its activities.

Main functionality

A typical job description for an occupational safety specialist includes a section called “functions.” As a rule, the purpose of this employee is to supervise the enterprise’s compliance with legislation, as well as other regulations on labor protection and safety, including internal local ones.

In addition, the specialist’s functionality includes the development, preparation and implementation of measures related to the prevention and prevention of occupational diseases and possible accidents that arise during the work process. The HSE engineer must draw up reports on his activities and submit them within the allotted time frame, and provide employees with a methodological basis to ensure their safety.

State labor inspectors

State labor inspectors, in order to carry out federal state supervision over compliance with labor legislation and other regulatory legal acts containing labor law norms, conduct scheduled and unscheduled inspections throughout the Russian Federation of any employers: organizations, regardless of their organizational and legal forms and forms of ownership, and also employers – individuals.

The subject of the inspection is compliance with the requirements of labor legislation and other regulatory legal acts containing labor law norms, compliance with orders to eliminate violations identified during inspections and to take measures to prevent violations of labor law norms and to protect the labor rights of citizens.

The grounds for conducting an unscheduled inspection are:

- Expiration of the deadline for the employer to fulfill the order issued by the federal labor inspectorate to eliminate the identified violation of the requirements of labor legislation and other regulatory legal acts containing labor law standards;

- Admission to the Federal Labor Inspectorate:

- appeals and applications from citizens, including individual entrepreneurs, legal entities, information from government bodies (officials of the federal labor inspectorate and other federal executive bodies exercising state control and (or) supervision, local government bodies, trade unions, from funds mass information about facts of violations by employers of the requirements of labor legislation and other regulatory legal acts containing labor law norms, including labor protection requirements, which resulted in a threat of harm to the life and health of workers;

- appeals and statements from citizens, including individual entrepreneurs, legal entities, information from state authorities, local governments, trade unions, from the media about the facts of evasion of the execution of an employment contract, improper execution of an employment contract or the conclusion of a civil law contract, in fact regulating labor relations between employee and employer;

- an employee’s appeal or statement about the employer’s violation of his labor rights;

- an employee’s request to conduct an inspection of labor conditions and safety at his workplace;

- the presence of an order (instruction) from the head (deputy head) of the federal labor inspectorate to conduct an unscheduled inspection, issued in accordance with the instructions of the President of the Russian Federation or the Government of the Russian Federation or on the basis of the request of the prosecutor to conduct an unscheduled inspection as part of the supervision of the implementation of laws on materials received by the prosecutor's office and appeals.

An unscheduled on-site inspection in the event of an employee’s request or statement about the employer’s violation of his labor rights can be carried out immediately with notification of the prosecutor’s office in the manner established by federal law, without coordination with the prosecutor’s office.

Preliminary notification of the employer about an unscheduled on-site inspection is not allowed in the event of an employee’s request or statement about the employer’s violation of his labor rights or the employee’s request to conduct an inspection of labor conditions and safety at his workplace.

Main responsibilities of a labor protection specialist

To carry out his functions, an engineer performs certain duties. Namely:

- identifies harmful and dangerous production factors;

- conducts an analysis of the causes of accidents and injuries at work, and employee illnesses;

- when carrying out certification of workplaces, assessing the safety of equipment, certification of premises, takes an active part and provides assistance to the specialists who organized these events;

- informs the team on behalf of management about the existing working conditions, measures taken to protect workers from the dangerous effects of harmful factors on site.

The main responsibilities of an HSE engineer also include:

- taking part in the preparation of collective agreements and contracts on labor protection;

- development and implementation of measures to prevent injuries, occupational diseases, accidents, eliminate violations of safety regulations, together with the heads of departments;

- compiling lists for periodic medical examinations of employees;

- compiling a list of professions that are entitled to benefits and compensation for work in difficult, dangerous and harmful conditions;

- preparing and conducting introductory briefings for newly hired employees;

- compilation and presentation of labor safety reports in the required forms and terms.

The instructions usually supplement the wide range of duties that an occupational safety specialist performs by accepting applications, complaints and letters that come from employees and touch on occupational safety and health issues, writing proposals to the administration to eliminate them and preparing responses to applicants.

How to create a labor protection service

The manager’s decision to create an occupational safety service as a structural unit or to hire an occupational safety specialist is reflected in the order. Changes are also made to the staffing table if a unit or specialist position was not provided for in the organization’s staff.

A Regulation on the Labor Protection Service is being developed, which establishes the goals and objectives of such a service, rights and responsibilities, the procedure for interaction with other departments, as well as job descriptions for labor protection specialists, taking into account the Qualification Directory of positions for managers, specialists and other employees, approved by the Resolution of the Ministry of Labor Russia dated August 21, 1998 No. 37 (hereinafter referred to as the Directory of Positions).

The job directory establishes the following qualification requirements for the position of head of the labor protection service: higher professional education in the field of training “technosphere safety” or corresponding areas of training in ensuring the safety of production activities, or higher professional education and additional professional education (professional retraining) in the field of labor protection, work experience in the field of labor protection for at least 5 years.

If the head of an organization with less than 50 employees assigns the responsibilities of a labor protection specialist to himself, then an order is not required, since he is already obliged to ensure safe conditions and labor protection in the organization by virtue of Art. 212 Labor Code of the Russian Federation.

Along with occupational safety specialists, the manager must undergo special training in occupational safety and health within the scope of job responsibilities upon entering work within the first month, then as necessary, but at least once every three years (clause 2.3.1, 3.2 The procedure for training in labor protection and testing knowledge of labor protection requirements for employees of organizations, approved by Resolution of the Ministry of Labor of Russia, Ministry of Education of Russia dated January 13, 2003 No. 1/29).

All employees of the organization are also required to undergo training and knowledge testing on labor protection. For all persons entering work, as well as for employees transferred to another job, the employer or a person authorized by him is obliged to provide instructions on labor protection, organize training in safe methods and techniques for performing work and providing first aid to victims (Article 225 of the Labor Code of the Russian Federation).

Thus, measures to ensure compliance with labor protection rules and standards include:

- issuance of an order on the creation of a labor protection service (introducing the position of OSH Specialist into the staffing table);

- approval of the Regulations on labor protection and job descriptions for specialists of the labor protection service;

- development of labor protection instructions for employees of the organization;

- development and execution of accounting documentation reflecting labor protection activities;.

In each organization, the labor protection service must also develop and maintain the following local documents: logs of registration of introductory briefing on labor protection; training at the workplace (initial, repeated, targeted, unscheduled) on safe labor methods; fire safety briefing log; schedule for annual testing of workers' knowledge of labor protection; log of industrial accidents and much more.

If there are harmful and (or) dangerous factors in the working environment at the enterprise, a List of work of increased danger or performed in dangerous and harmful conditions is developed and approved; List of professions and jobs for which workers need to undergo a medical examination; Logbook for registration of work permits for high-risk work; List of free protective clothing, safety shoes and other personal protective equipment; List of workplaces to be equipped with collective protective equipment; List of distribution of flushing and neutralizing agents; List of positions exempt from on-the-job training; List of positions for the 1st group on electrical safety; List of positions for 2-5th gr. according to EB; List of positions (professions) for preliminary and periodic medical examinations, etc., etc.

Exercising control

But the work of this engineer is not limited to this. Most of it consists of carrying out comprehensive control measures in the field of safety of the enterprise’s activities, as the standard job description tells us. The occupational safety specialist is required to monitor the following points:

- to what extent are labor safety measures prescribed in collective agreements, labor protection agreements, and others aimed at creating safe and healthy working conditions implemented;

- Are safety instructions available in each department?

- whether tests and technical examinations of production equipment were carried out on time;

- whether the aspiration and ventilation systems, safety and protective devices of the mechanisms function effectively;

- Are annual scheduled inspections of the grounding of electrical installations and electrical wiring insulation carried out?

- whether workers are provided with the required special clothing and footwear, what condition they are in, whether they are cleaned, washed and repaired in a timely manner.

Availability of rights

What other points should the job description contain? A labor protection specialist, in addition to his duties, has certain rights. These include familiarization with draft orders of management relating to its work. He can submit proposals for improvement of the occupational health and safety system operating at the enterprise for consideration by his manager.

The rights of a labor protection engineer include receiving information and documents from departments that consider issues within his competence, engaging specialists from any departments and divisions to solve the tasks assigned to him (with the permission of the manager, or if this moment is provided for by the internal regulations of the structural divisions) .

General requirements for drawing up job descriptions

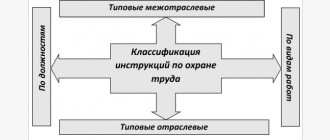

A typical job description for a labor safety engineer usually consists of five sections:

General provisions. This section describes the requirements for a specialist, how appointment to a position is made, what the specialist is guided by and to whom he directly reports.

- Job responsibilities. Description of the work performed by the employee in the professional field.

- What a specialist should know. Usually a list of regulatory legal acts that are necessary for carrying out production activities is compiled.

- Rights. The rights of the employee when performing job duties are listed.

- Responsibility. It is established based on the requirements of legislative documents. The job description may be published at the enterprise in a different edition, but the main points must be clearly indicated there.

Responsibility

What responsibilities does an occupational safety specialist have? The standard instruction provides that he must be held accountable to the fullest extent for failure to fulfill or improper fulfillment of the requirements specified in the job description, within the limits of the current labor legislation of the Russian Federation.

Also, the HSE engineer is responsible for offenses committed by him in the course of his work, for material damage caused to the enterprise or third parties, for providing false information regarding the performance of his functions, and for failure to take measures to eliminate identified safety violations.

Documents for work

To carry out his job duties, a labor protection specialist requires the following documents:

- regulations governing the operation of the labor protection system at the enterprise;

- fire safety rules;

- safety and labor protection instructions;

- magazines, posters, stands, safety and labor protection signs;

- instructions for working in high-risk workplaces;

- technological and other documents.

Depending on the specifics of the enterprise’s activities, this list may be supplemented by a number of other administrative and regulatory acts.

Contents of the “General Provisions” section

Drawing up instructions for a labor protection specialist

The first section of the instructions states:

- Requirements for a candidate or employee of the labor protection service, including his experience and moral and business qualities.

- How is appointment or dismissal from official duties made? Typically, an administrative document for the enterprise is issued, signed by the employer, which is then familiarized to the employee against a signature indicating the date of familiarization.

- The subordination of the safety specialist, as a rule, is assigned to the chief engineer, since technical issues need to be regulated.

- You can also write down a clause: if an OT engineer is temporarily absent, who can be assigned to perform functional duties, that is, the requirements for the candidate.

Items related to “General Provisions” from the job description can be rearranged, added and changed. This depends on the specifics of the enterprise's activities.