Ensuring safety at work is, in accordance with the Labor Code of the Russian Federation, the responsibility of the employer. This means that the enterprise must create a labor protection and industrial safety management system that will create risk-free working conditions for each employee that meet the established requirements.

The safety of technological processes and production, labor protection of employees is achieved through a number of measures:

- appointment of responsible employees;

- formation of a program of measures with the help of which the employer establishes industrial safety and labor protection in the organization;

- development and implementation of an internal control system;

- analysis of potential risks and their management;

- documentation, generation of reports, familiarization of employees with documents.

Let's take a closer look at how occupational health and safety at work is ensured.

Is it necessary to have a separate department for occupational safety?

Labor protection and industrial safety at an enterprise is, in accordance with Art. 212 of the Labor Code of the Russian Federation, the employer’s area of responsibility. He is also responsible for preserving the life and health of employees during the work process.

In accordance with the requirements of Art. 217 of the Labor Code of the Russian Federation, in order for an institution to create a safe working environment, occupational health and safety must be provided either by an individual specialist or by an entire department (depending on the number of employees).

Options that will make it possible to ensure labor protection in industry and in organizations are as follows:

- if the number of employees is more than 50 people, it is necessary to create an occupational safety service (for example, an industrial safety and labor protection department) or introduce the position of an occupational safety specialist (with the required level of training or experience in the field of activity);

- when the number of employees is less than 50 people, the employer decides for himself (depending on the specifics of production) whether to create an entire service or introduce the position of an occupational safety specialist.

If the employer does not have such a service, there is no full-time employee, this functionality is taken over by:

- employer-individual entrepreneur;

- head of the organization;

- employee authorized by the manager;

- a special organization (or specialist) operating in the field of occupational safety, which is involved under a GPC agreement.

If the responsibilities of labor protection and industrial safety managers will be performed by a special division of the enterprise (or an occupational safety specialist), the required number is determined using the Decree of the Ministry of Labor of the Russian Federation dated January 22, 2001 No. 10 and dated February 8, 2000 No. 14. Thus, if there are less than For 700 employees, it is optimal to have one occupational safety specialist; with a larger number, a department of several people can be created.

The employee’s right to safe working conditions

The Constitution of the Russian Federation guarantees every citizen the right to work in conditions that meet safety and hygiene requirements. This right is specified and guaranteed by the Labor Code.

Based on the basic provisions of the law, every employee has the right:

- to a safe workplace that meets labor protection requirements;

- compulsory social insurance against occupational diseases and industrial accidents;

- obtaining reliable information about working conditions in the organization, about the risk to employee health and about labor protection at work;

- an employee has the right to refuse to perform work if there is a danger to his life and health and labor safety requirements are violated at the enterprise;

- to provide personal and collective protective equipment at the expense of the employer and in accordance with labor protection requirements;

- ensuring safe production methods at the expense of the employer;

- the right to professional retraining in the event of liquidation of a workplace due to violation of labor protection requirements at the expense of the employer;

- the right to appeal to government authorities, the employer, trade unions and other authorized bodies on labor protection issues;

- an extraordinary medical examination in accordance with medical indications and with the obligatory preservation of the place of work and average earnings for the duration of the examination;

- the right to compensation established by law or an employment contract, provided that the employee is involved in heavy work with harmful working conditions.

So, the Labor Code of the Russian Federation legally enshrines a wide range of employee rights to work, which must meet all safety requirements and standards.

What does labor protection do?

The area of responsibility for labor protection is extremely wide. It includes:

- activities to ensure compliance by enterprise employees with occupational safety requirements;

- monitoring compliance by employees with legislation in the field of occupational safety and local regulations of the employer;

- prevention of injuries at work, occupational diseases, improvement of working conditions;

- consultations on occupational safety issues, implementation of best practices;

- accounting of the causes of injuries and occupational diseases, their analysis;

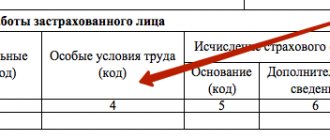

- participation in a special assessment of operating conditions;

- assistance to department heads who create lists of professions subject to periodic medical examinations;

- generation of labor safety reporting;

- development of training programs;

- organizing occupational safety training in due time;

- formation of a list of positions for which there must be instructions on labor protection and industrial safety;

- informing about current regulations and requirements in the field of occupational safety.

Ways to prevent occupational injuries

Occupational safety in construction and labor protection

The main task of occupational safety is to prevent injuries at work or in an office, shopping center or industrial enterprise. For this purpose, a number of activities are also carried out, such as introductory, primary, periodic, unscheduled and ongoing TB training.

Note! All employees who begin their immediate duties for the first time undergo induction training.

This type of training introduces employees to:

- OT instructions;

- the reasons due to which accidents occur;

- the procedure for providing first aid (the employee must always be in a state of readiness to provide such assistance).

At the initial briefing, which is carried out already at the workplace, the employee is given a detailed disclosure of safety regulations at his workplace, and is also given an idea of the personal protective equipment that he should use in the event of an emergency situation (it is important to disclose this aspect because it can subsequently save the worker’s life).

Periodic briefings, as the name suggests, are carried out regularly. Their purpose is to test employees’ knowledge in the field of occupational safety. If the test is successful, it means that employees have knowledge of ensuring R&D. It follows from this that they are able not only to follow these conditions, but also to act correctly in the event of an emergency.

Unscheduled briefing is carried out when:

- commissioning of new equipment;

- changes in technical process;

- after accidents that occurred as a result of violations of labor safety conditions.

Routine briefings are carried out by managers on site in the event of a violation of occupational safety conditions. For example, during the construction of any facilities where safety regulations are violated (a typical example is the improper use of building materials), ongoing briefings are regularly carried out.

Labor Code of the Russian Federation

Where to train OT specialists

Where can an OT specialist get training? Training is provided by specially accredited organizations. This could be, in particular, the Institute of Occupational Health and Industrial Safety, other institutions, the Center for Occupational Health and Industrial Safety.

All employees must undergo special occupational safety training in the first month upon entry to work within the scope of the duties of the position. The following categories with at least five years of experience are exempt from this training:

- employees with the qualification of an engineer (specialist) in the safety of technological processes and production or in occupational safety;

- employees of federal and regional authorities in the field of control and supervision of occupational safety;

- teachers teaching the relevant discipline with experience without a break for five years.

The named categories have the right not to undergo training and testing of existing knowledge for one year after hiring. Further training occurs as needed, but at least once every three years. Such training for an OT specialist can be carried out by:

- training organization;

- employer if it has a commission that checks knowledge of occupational safety requirements.

However, the Ministry of Labor of the Russian Federation, in Letter No. 15-2/B-5568 dated December 29, 2015, expressed the opinion that it is necessary to train specialists in training organizations. Also, this requirement must be adhered to in order to avoid possible risks of prosecution under Parts 3, 5 of Art. 5.27.1 Code of Administrative Offenses of the Russian Federation.

You can get detailed information from, for example, the forum on labor protection and industrial safety, as well as the official website of the Ministry of Labor of the Russian Federation.

For what purpose are workplace conditions determined?

Taking into account the conclusions of the SOUT, measures are being developed to help reduce the indicators:

- worker morbidity;

- industrial injuries.

The reason for assessing the state of workplaces unscheduled may be:

- opening new production sites when it is necessary to determine the safety of working conditions;

- introduction of new technologies or equipment that can change the qualitative indicators of impact, for example, noise, vibration;

- obtaining instructions from supervisory authorities;

- change of materials and raw materials necessary for production or personal and collective protective equipment, which may also change the degree of adverse impact on the health of workers;

- employees receiving work-related injuries or identifying cases of occupational diseases;

- receipt of motivated proposals from trade unions responding to workers’ complaints.

Taking into account the level of potential danger of objects, they are registered in the state register.

Ensuring safety in the workplace includes a whole range of measures

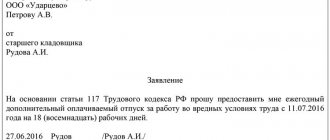

Persons working in known dangerous and harmful conditions are guaranteed to have the right:

- apply for a pension early, taking into account the presence of a certain preferential length of service;

- receive monthly compensation payments;

- for additional days of paid leave to restore health;

- free special food, milk, other benefits.

What is production control

Production control is measures aimed at ensuring compliance with established sanitary and hygienic standards, regulations, and rules for the creation of products, works and services that do not pose a risk to humans.

The employer is obliged to organize and carry out control (Article 11 of the Federal Law No. 52-FZ of March 30, 1999).

Control can be carried out using the results of a special assessment of working conditions and certification of places of work.

The procedure is determined by the joint venture dated July 13, 2001 No. 1.1.1058-1.

The objects of control include:

- industrial, public buildings;

- sanitary protection zones;

- transport;

- technical equipment, technical processes;

- raw materials, semi-finished products, finished products, waste.

Production control has the following types:

- Technical (checking the compliance of the production process with standards).

- Energy (energy saving, resource control).

- Environmental (compliance of activities with environmental safety standards).

- Sanitary (compliance of processes with sanitary standards).

- Financial (use of materials resources).

Labor safety standards in the workplace

The key meaning of labor protection for employees of an organization is to ensure that the safest working conditions are ensured at work places. Workplaces can be an office, a workshop, a market stall and all those premises where the employee performs his direct duties. The nuances of labor protection depend on the specifics of the activity.

There are standards for creating safe conditions for various types of organizations. Taking into account all the features, we can highlight the requirements that the organization must always adhere to:

- optimal correspondence between work and rest schedules,

- equipping the workplace with the tools needed to carry out work activities,

- working conditions that do not harm the health of the employee.

What documents are needed

The organization must develop a production control program depending on the type of activity. It is drawn up randomly and approved by the manager.

The enterprise is also developing regulations on production control. The list of issues that need to be reflected is included in Federal Law No. 116-FZ dated July 21, 1997. The document can be developed either by an employee of the enterprise with the appropriate qualifications or by third-party organizations providing control services. The document is approved by the head of the institution or department for which it was developed. Subsequently, it is transferred to the territorial agency of Rostechnadzor.

If the employer does not carry out control, this is a violation of the legislation on sanitary and epidemiological welfare and is punishable by a fine of up to 20,000 rubles or suspension of activities for up to 90 days.