Flushing and neutralizing agents for workers - list

Washing, protecting and regenerating products that should be provided to employees include:

- soaps and detergents for face and body;

- cleansing gels and pastes;

- substances that absorb moisture and moisturize the skin;

- substances that repel moisture;

Flushing and protective agents

- combination agents;

- gels and creams against irritations due to environmental conditions;

- disinfectant solutions and gels;

- means protecting against insect bites;

- regenerating restorative creams and emulsions for workers.

Each tool is issued for specific types of work. It is legally required that work without them is not permitted, as the worker’s health may be at risk.

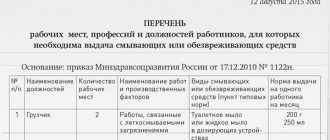

Issuance of flushing and neutralizing agents by profession - standard

Standard standards for issuing personal protective equipment

In accordance with established standards, funds must be issued for certain categories of employees. This is how protection is used when working with various hazardous substances. Moisture-absorbing creams and gels protect workers when working with insoluble substances, such as varnishes, lubricants when working on cars, petroleum products, etc. Hydrophobic agents, on the contrary, are used to protect against water-based substances: they are issued when working with acids and alkalis and salts.

Attention! If it is difficult to determine exactly which specific substance will have to be worked with, combined mixtures are used.

Anti-irritation substances are useful for welding work, activities under increased ultraviolet radiation and when exposed to temperature and wind.

Work with possible bacteriological contamination should not be carried out without disinfectants, which should be applied to all exposed areas of skin or clothing. They will disinfect, protect and maintain the health of the worker.

During seasonal work, protection from blood-sucking insects or the bites of poisonous arthropods is especially important. In this case, protective substances of a biological nature must be provided.

Soap and detergents are useful for work with possible contamination. Moreover, these substances are also divided into several levels, depending on the difficulties that arise during rinsing.

Restorative creams and gels can be useful in all of the above cases, if, despite increased attention to protection, it was not possible to avoid the negative impact of the environment on humans.

To whom and how much

Standard standards for the free distribution of cleaning agents and disinfectants to employees were approved by Order of the Ministry of Health and Social Development No. 1122n dated December 17, 2010.

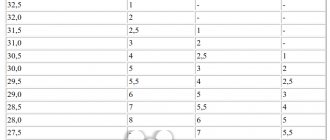

| No. | Types of flushing and (or) neutralizing agents | Name of work and production factors | Issue rate per 1 employee per month |

| I. Protective means | |||

| 1 | Hydrophilic agents (moisture-absorbing, skin moisturizing) | Work with organic solvents, technical oils, lubricants, soot, varnishes and paints, resins, oil and petroleum products, graphite, various types of industrial dust (including coal, metal, glass, paper and others), fuel oil, fiberglass, lubricants oil-based liquids (hereinafter referred to as coolants) and other water-insoluble materials and substances | 100 ml |

| 2 | Hydrophobic agents (repellent moisture, drying skin) | Work with aqueous solutions, water (provided for by the technology), water-based coolants, disinfectants, solutions of cement, lime, acids, alkalis, salts, alkali-oil emulsions and other water-soluble materials and substances; work performed in rubber gloves or gloves made of polymer materials (without natural lining), closed safety shoes | 100 ml |

| 3 | Combined action agents | Work under alternating exposure to water-soluble and water-insoluble materials and substances specified in paragraphs 1 and 2 of these Standards | 100 ml |

| 4 | Products to protect the skin from negative environmental influences (from irritation and skin damage) | External, welding and other work associated with exposure to ultraviolet radiation in ranges A, B, C or exposure to low temperatures and wind | 100 ml |

| 5 | Means for protection against bacteriological harmful factors (disinfectants) | Work with bacterially hazardous environments; when the workplace is located remotely from stationary sanitary facilities; work performed in closed special shoes; with increased requirements for hand sterility in production | 100 ml |

| 6 | Means for protection against biological harmful factors (from arthropod bites) | External work (seasonal, at temperatures above 0° Celsius) during the period of activity of blood-sucking and stinging insects and arachnids | 200 ml |

| II. Cleansers | |||

| 7 | Soap or liquid detergents including: | Work related to easily washed off contaminants | |

| for washing hands | 200 g (toilet soap) or 250 ml (liquid detergents in dispensing devices) | ||

| for body wash | 300 g (toilet soap) or 500 ml (liquid detergents in dispensing devices) | ||

| 8 | Solid toilet soap or liquid detergents | Work involving hard-to-remove, persistent contaminants: oils, lubricants, petroleum products, varnishes, paints, resins, adhesives, bitumen, fuel oil, silicone, soot, graphite, various types of industrial dust (including coal, metal) | 300 g (toilet soap) or 500 ml (liquid detergents in dispensing devices) |

| Work in coal (shale) mines, in open-cast mines, in processing and briquette factories, in mine construction and mine installation organizations in the coal industry | 800 g (toilet soap) or 750 ml (liquid detergents in dispensing devices) | ||

| 9 | Cleansing creams, gels and pastes | Work involving hard-to-remove, persistent contaminants: oils, lubricants, petroleum products, varnishes, paints, resins, adhesives, bitumen, fuel oil, silicone, soot, graphite, various types of industrial dust (including coal, metal) | 200 ml |

| III. Regenerating, restorative agents | |||

| 10 | Regenerating, restorative creams, emulsions | Work with organic solvents, technical oils, lubricants, soot, varnishes and paints, resins, petroleum and petroleum products, graphite, various types of industrial dust (including coal, glass and others), fuel oil, water- and oil-based coolants, with water and aqueous solutions (provided for by the technology), disinfectants, solutions of cement, lime, acids, alkalis, salts, alkali-oil emulsions and other working materials; work performed in rubber gloves or gloves made of polymer materials (without natural lining); negative impact of the environment | 100 ml |