Home / Labor Law / Occupational Safety and Health

Back

Published: 08/10/2016

Reading time: 11 min

0

7141

Although every citizen, in accordance with the Constitution of the Russian Federation, is guaranteed the right to safe work, in some areas of activity such conditions cannot be provided.

This is due to the presence of harmful factors in the workplace, the impact of which on employees is a feature of the activity.

It is worth considering these factors in more detail, including the example of individual professions, and also determining their impact on the human body.

- Legislation

- What it is? Physical

- Chemical

- Biological

- Psychophysiological

- Accountant

Types of harmful factors

Harmful production factors mean factors in the working environment that can contribute to the development of pathologies, decreased performance, and increased incidence of infectious diseases.

If harmful factors have too long an impact on a person, then they can already become dangerous. That is, lead to a sharp and sudden impairment of health.

Harmful and dangerous factors can be of natural, or natural, and anthropogenic origin, that is, arising due to human fault.

If we consider the nature of the impact on humans, production factors can be divided into the following groups:

- Physical.

- Chemical.

- Biological.

- Psychophysiological.

Each of the groups can also be of natural or anthropogenic origin.

Legislation

Regulation of the labor sphere in matters of the presence of harmful production factors and compensation to workers for this is carried out by certain regulations, namely:

- Labor Code of the Russian Federation. In particular, this document establishes as a mandatory procedure for subordinates working in hazardous conditions to undergo medical examinations (Articles 69, 212, 213, 266, 328).

- Industry documents developed and approved for various fields of activity.

- Order of the Ministry of Health and Social Development of the Russian Federation dated April 12, 2011 N 302n “On approval of lists of harmful and (or) hazardous production factors and work, during which mandatory preliminary and periodic medical examinations (examinations) are carried out, and the Procedure for conducting mandatory preliminary and periodic medical examinations (examinations) of workers engaged in heavy work and work with harmful and (or) dangerous working conditions.”

In particular, this document provides a list of those factors (harmful or dangerous) under which a medical examination is mandatory for subordinates, as well as the procedure for carrying out this procedure.

In addition, it provides a specific list of factors according to their main types.

Physical hazardous and harmful production factors

Natural or natural factors include:

- Air temperature.

- Humidity.

- Air masses.

- Atmosphere pressure.

- Solar radiation.

Anthropogenic harmful factors include:

- Increased level of dust in the workplace.

- Strong vibration.

- High noise level.

- Exposure to ultrasound or static electricity.

- The influence of electromagnetic fields.

- Laser radiation.

- Exposure to electric current.

- Work at high altitude.

- High or low equipment temperature.

- Moving and working mechanisms and equipment.

- Weapons of mass destruction.

- Lighting in the workplace.

As you can see, the list of harmful factors is quite large. All of them can have a negative impact on human health, especially with constant and long-term exposure.

Main sources of harmful physical factors

- The air of the room where the labor activity of the enterprise is carried out in terms of production:

- With dust content in excess of the norm.

- Contaminated with various types of gaseous, or in the form of liquid emulsion, harmful substances.

- With different from the norm, high or low humidity.

- With increased driving speed.

- Reduced or increased, relative to the standard value, the temperature of the working room.

- Increased indicators, relative to normal:

- Noise level.

- Vibration values.

- Indicators of static electricity.

- The brightness of the light and the pulsation of its flow.

- Barometric pressure.

- Temperature of the treated surface.

- Insufficient indicator values:

- Lighting and contrast of the working area.

- Contrast.

- Barometric pressure, including a sharp change in its value.

- Moving machines and equipment mechanisms, including:

- Elements of a product and its blanks in the process of its creation.

- Moving parts of mechanical equipment.

- network voltage.

Chemical factors of the production environment

If we talk about natural substances, then these are those that can easily enter the body with air, food or drink. These include: amino acids, proteins, fats, carbohydrates, vitamins, microelements and other substances.

Factors of anthropogenic origin from the chemical group include:

- Increased gas pollution in production.

- Impact of toxic substances on humans.

- Contact with benzene and toluene vapors.

- Oxides of sulfur and nitrogen.

- Aggressive liquids, such as alkalis or acids.

Chemical harmful factors can be divided into groups depending on the nature of the effect on the human body:

- Generally toxic, cause poisoning of the body. For example, carbon monoxide, mercury, lead.

- Annoying. They affect the respiratory system, causing coughing and sneezing. These include chlorine and ammonia.

- Sensitizing. Can cause allergic reactions. Most often these are formaldehydes and varnishes based on nitro compounds.

- Carcinogenic. Provoke the development of tumors. These include: nickel, chromium compounds, amines, asbestos.

- Mutagenic. They increase the risk of mutations, especially in germ cells, which will certainly affect the offspring. Provocateurs can be mercury, styrene, magnesium.

Harmful production factors can be divided into several classes according to the degree of danger:

- Extremely dangerous.

- Highly hazardous substances.

- Moderately dangerous.

- Low risk.

Typically, the source of contamination of industrial premises with hazardous chemicals is raw materials for processing, components for equipment, or the finished product itself.

Ways of penetration of harmful substances into the human body

Most often, dangerous and harmful production factors affect the body through the respiratory system. This is the most dangerous because the lungs have a large absorptive surface area of the alveoli. They are washed with blood, which means that dangerous substances quickly enter all vital organs.

The second route of penetration of harmful substances is the gastrointestinal tract, but this happens much less frequently. This is only possible if the rules of personal hygiene and labor safety in the workplace are not followed. In this case, all toxic substances enter the liver and are partially neutralized there.

Substances that dissolve well in fats and proteins can penetrate into the body through the skin. Severe cases of poisoning are usually caused by highly toxic substances. This may include: tetraethyl lead, methyl alcohol, etc.

In the body, hazardous substances are not distributed evenly, but accumulate in certain places. For example, copper most often accumulates in the skeletal system, manganese in the liver, and mercury in the kidneys and intestines.

Biological hazards

Biological hazards are those that originate from living objects. Carriers of biological hazards are all habitats (air, water, soil), flora and fauna, and people themselves.

Biological hazards result in various diseases and injuries of varying severity, including fatal ones.

Biological hazardous and harmful factors are:

- pathogenic microorganisms (bacteria, viruses, fungi, etc.);

- plants and animals.

Bacteria are typical representatives of microorganisms. Bacteria are ubiquitous and resilient. They do not die either in permafrost or in space, and exposure to a dose of radiation lethal to humans is not dangerous for them.

Bacterial diseases are: plague, tuberculosis, meningitis, tetanus, etc.

Viruses are tiny cellular particles consisting of nucleic acid and a protein shell. Viruses are completely dependent on the metabolism of the host cell.

Viral diseases are: smallpox, influenza, measles, mumps, rubella, etc.

Pathogenic fungi cause diseases in plants, animals and humans.

About 700 types of diseases can cause severe and fatal infections.

According to the degree of toxicity, plants are divided into:

- poisonous (white acacia, elderberry, ivy). Potato shoots and seeds are also poisonous due to their solanine content;

- deadly poisonous (henbane, datura, belladonna).

Animals:

- scorpions - the sting of a scorpion is very painful (swelling, chills, and fever);

- mites – cause the disease scabies.

Biological hazards

This group includes the following harmful environmental factors:

- Pathogenic microorganisms and their metabolic products.

- Microorganisms-producers.

- Protein preparations.

Hospital workers, travelers, and people who work outdoors for long periods of time are at greater risk of contracting various diseases than others. Upon contact with plants or animals, an allergic reaction of the body and infection with helminths may occur.

Exposure to mold, fungi, and grain dust can cause various infectious ailments and skin diseases. Dermatitis is a common diagnosis on sick leave certificates for people working with hazardous substances.

There is even some pattern in the spread of diseases associated with professional activities. Medical personnel are most often infected with tuberculosis and hepatitis, fungal infections are typical for granary workers, and chronic lung disease is an occupational disease among light industry workers. Those working in the livestock industry are susceptible to bacterial infections.

Psychophysiological factors

Harmful factors of the psychophysiological group can be divided into two categories:

- Physical overload.

- Neuropsychic overload.

Physical, in turn, can be static and dynamic. Together they characterize the severity of the worker’s work. This means loads on the musculoskeletal system and the cardiovascular system.

The severity of labor can be characterized by the size of the load that the worker is forced to lift or move, the number of movements necessary to carry out production processes.

Neuropsychic overload can characterize the intensity of work. The classification of harmful and dangerous factors in this category may include the following types:

- Mental overstrain.

- Emotional stress.

- Monotonous work.

- Work and rest schedule.

- Overstrain of the senses.

It is necessary to take into account that the same harmful production factors can simultaneously belong to several categories.

Impact of vibration and its elimination

Vibration is included in the list of harmful production factors. It can be classified into several categories:

- By transmission method: general and local.

- In its direction: vertical and horizontal.

- By exposure time: temporary and permanent.

As a result of constant exposure to this factor, not only the nervous system begins to suffer, but also the musculoskeletal system and the analyzer system. Workers who are forced to work in such conditions often complain of headaches, dizziness, and motion sickness.

If we add the influence of accompanying factors, such as humidity, high temperature, noise, then this only increases the harmful effects of vibration.

To protect against it, the following measures can be proposed:

- Replacement of equipment with more technologically advanced ones.

- Use of soft coatings on vibrating parts of instruments or equipment.

- Installation of units on a solid foundation.

Classes of working conditions by degree of danger

Any production must have its own standards, according to which the production process is carried out. First of all, these are hygiene standards that make the work of workers safe for their health.

Working conditions can be qualified taking into account existing deviations from established standards. Based on all the criteria, working conditions can be divided into several classes:

- Class 1 is the most optimal conditions under which everything is done to maintain health and improve performance.

- Class 2 – acceptable working conditions. In general, they comply with accepted standards, and some deviations are easily eliminated during rest.

- Class 3 – harmful conditions. Workers are constantly exposed to harmful factors, the levels of which exceed all acceptable standards. As a result, the health of employees is seriously harmed.

Harmful working conditions, in turn, are divided into several degrees:

- 1st degree. Working conditions cause reversible changes in workers' health, but increase the risk of developing diseases.

- 2nd degree. Exposure to harmful factors causes persistent disruption in the functioning of the body. Temporary loss of performance and initial signs of occupational diseases may occur.

- 3rd degree. There is a sharp increase in mild occupational pathologies.

- 4th degree. Severe forms of occupational diseases.

One more class of working conditions can be distinguished - dangerous or extreme. Factors in this group can cause danger to human life and the manifestation of acute occupational injuries.

Maximum permissible concentrations of harmful substances

No matter how harmful the production may be, it must comply with the maximum permissible concentrations of hazardous substances.

MPC (maximum permissible concentration) is a concentration of substances in the workplace that, with daily exposure, does not cause illness or health problems.

Maximum concentration limits for harmful substances are often used in the following cases:

- When drawing up projects for production workshops, technological processes, equipment, ventilation systems.

- When monitoring the quality of workers’ working conditions in production.

All harmful substances have their own maximum permissible concentrations; this depends on their effect on the human body. Lead, beryllium, and manganese are considered the most dangerous.

Highly hazardous substances are chlorine, hydrogen fluoride, phosgene. Tobacco and methyl alcohol pose a moderate danger. But ammonia, gasoline, acetone, ethyl alcohol are low-hazard substances.

How to determine the degree of exposure to harmful factors on a person

The workplace must undergo a special assessment, which is carried out by the OSH committee.

As a result of the work of this commission:

- The employee is surveyed about what he does while working. For example, how much time does he spend on direct work and how much time does he spend on auxiliary work? That is, the percentage of interaction with harmful factors is revealed;

- Next, an instrumental assessment of the conditions of the labor process is carried out, that is, all factors affecting it are measured. Afterwards, the indicators are recorded separately or examined using laboratory methods;

- Based on the research conducted, it turns out that the maximum permissible concentration of the harmful substance exceeds the standards. On the basis of this, classification is made to the hazard class.

Ways to protect workers from harmful production factors

All means of protection can be divided into:

- Collective

- Individual.

Collective means involve the simultaneous protection of a large number of workers. They are divided into several classes:

- To normalize the air environment. This includes ventilation systems and air conditioners.

- To bring lighting in the workplace to normal: various lamps, lamps that can provide good lighting.

- To protect against harmful and dangerous factors.

If the enterprise has a high noise level, then the walls are covered with materials that absorb sound, special covers are put on the operating mechanisms, and workers are given earplugs.

To prevent injury on the equipment, all hazardous areas are fenced on all sides. Locking buttons are installed on the doors and dampers, which will not allow them to be opened until the mechanism completely stops working.

Workers dealing with electricity are required to be provided with rubber gloves, boots or galoshes. Signal lights and safety signs are installed on the equipment.

If work is carried out at height, then this place must be fenced.

If collective methods are not able to provide high-quality protection, then each worker in hazardous production is given individual means. These include gowns, gloves, respirators, bandages, protective suits, etc.

Only safe work can lead to high quality and productive work.

Elimination of dangerous and harmful factors

At many enterprises, the production cycle is inextricably linked with the impact of harmful substances on humans. Administration and management should make every effort to try to eliminate or reduce this impact.

If you approach some processes thoughtfully, it turns out that sometimes toxic substances can be replaced with safer ones. Many managers do not agree to this for mercantile reasons. Thus, they save on the health of their subordinates. If replacement is not possible, then everything must be done to ensure that the employee is exposed to harmful and dangerous factors as little as possible. To do this, the enterprise, at its own expense, is obliged to provide personnel with all possible means of protection.

In order to prevent negative impacts, the following measures should be taken:

- Local air purification.

- Air showering.

- Wearing protective clothing.

- Equipped rooms for rest.

- Accurate observance of working hours.

- Breaks are provided at certain intervals.

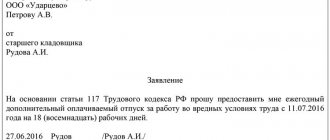

- Employees are provided with longer paid leave.

If all measures are taken in a timely manner and used comprehensively, then it can be argued that management is trying to provide its staff with safe working conditions.

Factors determining occupational safety

There are several diverse measures, the implementation of which will ensure safe working conditions.

- Organizational, consisting in carrying out rational document flow in the area of labor protection issues. It often happens that the head of an enterprise is not able to cover all areas of his control. Therefore, for high-quality and timely work to ensure the safe life of workers, the director can hire a specialist, and also distribute responsibilities between the heads of the department.

- Design activities include:

- In the correct design of buildings and structures of the enterprise.

- In the competent conduct of design work regarding the processed raw materials and the finished product or product.

- Technological, the meaning of which is the rational preparation and implementation of the requirements of the main production document of the enterprise - technological regulations.

- Operational imply correct operation, in accordance with the instructions:

- mechanisms,

- Equipment,

- Vehicle.

- The essence of sanitary and hygienic measures is to provide workers with:

- Personal protective equipment, devices, shoes and workwear.

- A room for heating and eating food.

- A toilet and, if necessary, a shower.

- Psychophysiological factors include conducting:

- Timely technological breaks.

- Lunch breaks.

- Regular production charging.

The most dangerous industries

The classification of harmful factors suggests that not all enterprises and industries can be considered hazardous to human health. The most dangerous types of work are considered:

- Installation and dismantling of heavy equipment.

- Transportation of cylinders with gas, acids, alkalis.

- Work at high altitude.

- Excavation work in areas where electrical cables are located.

- Work in mines, bunkers, wells, furnaces.

- Repair and cleaning of boilers, cyclones and other boiler equipment.

- Work in chemical plants.

We could go on and on about the most dangerous professions and industries, but humanity still cannot do without them, so we still have to work here, even despite the presence of health risks.