timing of working hours. This method involves accurate measurements of working time spent on standard work procedures by employees and the subsequent compilation of approximate indicators characteristic of a normal work process based on timing. This method demonstrates itself best in work involving a large number of similar operations, and is most often used to assess the labor efficiency of employees in blue-collar occupations.

Method- Working day photography method. In this case, the actual recording of the work of an employee or team is carried out directly during a certain period of time, most often one working day. After this, an actual analysis is carried out of the feasibility of performing certain operations by an employee or group of employees and the effectiveness of managing working time. This method is better suited than timekeeping for assessing lost working time by employees engaged in creative work or activities related to communications with other employees.

- Method for selective assessment of lost working time . This technique is relevant for large enterprises, where taking photographs of employees’ working day is impractical due to the large staff, and timekeeping due to the wide variety of positions and job responsibilities. This method involves selective chaotic recording of individual moments of working time, which, taking into account a large sample with a relatively long analysis and competent differentiation of inspection episodes, allows one to obtain fairly reliable results.

- Phototiming method . This technique includes a combination of methods of photography of the working day and timing of working time and requires the greatest costs on the part of the employer, however, it allows you to effectively evaluate the work of all employees, and also allows you to develop the best policy for optimizing the loss of working time at the enterprise.

What is lost working time?

Ineffective loss of working time refers to periods during which the employee did not perform work duties, which led to the loss of any income of the enterprise or delay in delivery of the object to the final buyer or consumer. This concept also includes periods of downtime if the culprit is an employee of the organization, due to his incompetence or negligent performance of job duties.

To rationally manage employee working time, you will need:

- Create a diagram of the labor process, taking into account the required number of workers and the time period during which it is necessary to obtain the result. It is also necessary to take into account the peculiarities of labor performance by each category of workers and identify the most optimal ratio for rest and work during the working day.

- The employer or other authorized person needs to draw up a time sheet, as well as determine tasks for each employee and the time for their completion, taking into account the specific distribution of work responsibilities.

- Compose and create your own method for studying losses and determine the most effective way to deal with them.

- Determine what actions of employees may relate to losses, as well as give a description and concept of lost working time.

The information obtained will help determine the effectiveness of the work team, their profitability and professionalism, as well as establish reserve forces that are directed to personal needs, bypassing the requirements of the organization.

As a general rule, loss periods are divided into large categories depending on their characteristics:

- Unproductive. This category of losses includes situations involving the correction of defects or systematization of a technological process that was disrupted due to the fault of the employee. Data on such situations are taken into account based on the amount of damage caused due to the fault of the employee.

- Planned. Temporary damage that was calculated based on adjustments to the existing plan. In this case, possible product losses due to poor-quality assembly of products are taken into account, since some percentage of defects is always found in production, regardless of the qualifications and activities of workers.

- Above plan, that is, downtime caused by insufficient implementation of the plan developed by the organization’s management.

- Full-day, which are defined as the inability to carry out labor activities during working hours. Most often, such situations arise due to the fault of the employer, for example, when there are insufficient raw materials for production or the provision of raw materials of inadequate quality, etc.

- General, which are expressed in general indicators of lost working time by all employees of the enterprise for the reporting period.

- Individual, expressed in determining the specific time of loss of one employee during the working day. These types of downtime include situations caused by violation of work schedules.

Lost working time is an integral part of the workday of any enterprise, however, with sufficient systematization of the work plan for each employee, you can change the situation by reducing downtime several times.

What kind of damage do they suffer?

Irrational use of working time leads to negative consequences:

- profit lost due to low labor productivity;

- violation of the norms of behavior established by the laws of the Russian Federation and local regulations;

- loss of customers and suppliers;

- decreased staff motivation.

To build a cost-effective time management system, you will need:

- draw up a scientifically sound scheme for designing, assessing and determining the resources necessary to obtain the result, the ideal ratio between the number of employees of various categories and tools;

- draw up time sheets, assignments, determine cost research methods;

- determine which costs are considered losses.

The combination of the above conditions allows us to correctly evaluate the reserve - part of the interval for subordinates to perform their immediate functions, which is not used for its intended purpose.

Unproductive

Intervals in the production of substandard goods, correction of defects or failures in the technological process are considered unproductive costs.

Such losses are calculated based on data on damage caused by the release of products that do not meet established standards.

Examples

To demonstrate the calculation of the parameter in question, we will use the numbers from the table below:

| Index | Designation | Value (million rubles) | |

| Current production costs | JV | 161200 | |

| Salary | Total staff | ZR | 33064 |

| Workers directly related to production | ZPR | 20150 | |

| Costs for the purchase of raw materials, basic and auxiliary materials, fuel, energy | MOH | 85000 | |

| Cost of resources used to produce defects | SB | 1000 | |

| Rework costs | IS | 160 | |

Let the working time fund (WF), which is defined as the product of the total number of employees, the average annual number of days of direct functions performed by each of them and the average shift duration, be equal to 270,270 man-hours.

Next, you will need to sequentially calculate some ratios:

- ZPR / SP * 100% = 20190 / 161200 * 100% = 12.5%;

- we determine the amount of wages in the costs of producing defective goods: SB * 12.5 / 100 = 1000 * 12.5 / 100 = 125 million rubles;

- ZPR / (SP - MZ) * 100% = 20190 / (161200 - 85000) * 100% = 26.44%;

- remuneration to employees for correcting substandard conditions: IS * 26.44 / 100 = 160 * 26.44 / 100 = 42.30 million rubles;

- average earnings of one worker per hour: ZR/FRV = 33,064 million rubles. / 270,270 person-hours = 122,337 rubles;

- non-productive working time = 42,300,000 / 122,337 = 345.76 man-hours.

Irregular working hours - what does it mean?

What to do if there is an error in the work book in the date of admission? Read.

Planned

Regulated costs include the time interval provided for completing the production task, adjusted for the actual number of workers.

Above plan

If one employee actually worked fewer days and hours than planned by management, then two more types of downtime can be identified.

In-shift

Costs of this type are typically associated with factors such as:

- repair of mechanisms and assemblies;

- shortened working hours for persons for whom benefits are established by law (minors, disabled people);

- a regulated break for feeding an infant.

To calculate costs, you will need the following indicators:

- planned (TP) and actual (TF) average working day;

- the nominal number of shifts for one labor unit during the year (DF);

- total number of employees (RS);

- duration of overtime performance of duties (OT).

The final formula looks like this:

(TP - TF) * DF * RS + TS.

All day

The main reasons for such losses are:

- problems in providing raw materials and energy resources;

- bringing substandard products to proper form;

- absence from work during vacation, sick leave, or other objective reasons.

Costs are calculated using the formula:

(DP - DF) * RS * TP, where

DP is the planned number of working days.

Are common

Costs are defined as the difference between the planned number of working hours required to manufacture products, multiplied by the number of the entire workforce, and the actual amount of time spent on production without taking into account overtime.

For 1 person

Any work process can be divided into several intervals used for certain purposes:

- preliminary stage allocated for receiving the task, materials, tools, familiarization with the documentation, instruction, adjustment of mechanisms;

- final, necessary for the transfer of finished products, tools, plans, disassembly of equipment;

- operational, spent directly on performing a specific procedure;

- auxiliary, used to load raw materials, remove the finished product, control product quality;

- service, designed to maintain the workplace in proper condition, ensuring the proper level of labor productivity.

Thus, the production of goods occurs only at the operational stage, but at the same time it is also impossible to do without other components.

Loss of working time for a particular employee includes downtime due to violation of discipline and for organizational and technical reasons.

To calculate costs per employee, you will need to collect information on actual costs and compare it with planned values.

Reducing lost working time

Reducing work losses is one of the most important tasks in any enterprise. In this way, you can optimize production and reach a new level of income while maintaining and improving the quality of the final product.

The main measures to reduce losses include:

- Carrying out a procedure for analyzing the organizational component of production activities, taking into account the capabilities of each group of workers.

- Increasing the use of equipment used to manufacture products, as well as systematizing zones and introducing new service facilities.

- Establishing the percentage of manufacturing defects, as well as the size of defects due to the fault of the organization’s employees due to their low qualifications or inability to work on the equipment offered by the manufacturer.

- Improving working conditions, including the introduction of additional bonus payments for production output, increasing the duration of vacation and other ways to motivate workers to improve productivity and the quality of the final product.

- Selection and installation of an automatic system for quality control of manufactured products using modern mechanisms and units.

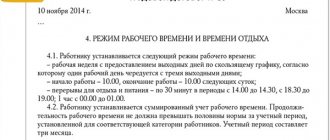

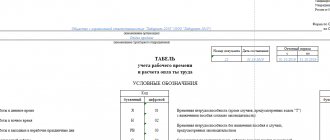

Working time is recorded in a special document that is accepted by the organization and used constantly - a time sheet. The legislation provides for the possibility of drawing up a report card in a unified form T-12 or T-13.

T-12 is used in the case of manual control of the arrival and arrival of organization employees on the territory of the enterprise, and T-13 - if control of visits to the place of work is carried out automatically.

Instead of a unified form, the management of an organization can use an independently developed accounting form, but it must contain the following information:

- Title of the document;

- date of preparation and adoption;

- full legal name of the enterprise;

- event;

- a value that is determined by established units of measurement;

- personal data of the responsible employee.

In order to rationally spend employees’ working time, the organization’s management needs to monitor the work processes of employees, establish and monitor discipline, and also constantly carry out various labor protection activities.

How to reduce

As a rule, measures to minimize damage to working hours include:

- monitoring the condition of equipment and timely repairs;

- improving workplace ergonomics;

- schedule optimization;

- strengthening labor discipline, approval of relevant local regulations;

- employee training;

- creation or improvement of a personnel motivation system.

Most often, choosing one of these measures is not enough to reduce labor losses at an enterprise. The most effective for this purpose is the use of an integrated approach that involves both working with personnel and optimizing organizational and technical conditions. The selection of certain corrective tools should be preceded by analytical work, including mathematical calculations regarding time leakage and standardization of the production process.

Are you sure that the labor process is carried out efficiently in your company?

If in doubt, first of all it is worth analyzing the totality of resources in terms of their use and distribution by type of cost.

Thus, it is possible to find out whether the causes of losses depend on the team or are not due to its activities.

Causes

Conventionally, temporary losses of employees can be divided into two large categories, on which the guilt of the employees themselves or the responsibility for the resulting delay of the manager or other authorized person depends.

Loss of working time due to the fault of the organization’s employees occurs in the following cases:

- employee being late or absenteeism without sufficient reason;

- unplanned absences of an employee during the performance of his work duties;

- making your own decision to end your work activity ahead of schedule;

- equipment downtime, if the employee is to blame for this state of affairs, in particular, due to improper use of labor tools;

- conducting negotiations and discussions that are not related to work activities;

- smoking breaks and “five minutes” of rest during work.

In addition to the guilt of the employees, there are situations in which the employer is the guilty party, since for some reason he initiated the lack of work, or the lack of work is not the fault of either the employee or the employer.

Such reasons include:

- impossibility of carrying out labor due to lack of raw materials for production;

- inaction of workers caused by the lack of electrical equipment of the enterprise;

- equipment breakdowns due to wear and tear or manufacturing defects;

- repair of equipment, as well as workshops and other technical premises on which the organization’s activities depend;

- employee going on maternity leave;

- the employee needs to apply for study leave;

- the enterprise produces low-quality products due to incorrectly drawn up technical specifications, as well as in the case of low-quality raw materials.

Any loss of working time can lead to adverse consequences in the form of loss of part of the income or destruction of the organization’s business reputation.

How to analyze the use of labor resources

Analysis of the use of labor resources begins with the preparation of documentation:

- report on the company's labor activity;

- employee time sheet;

- information on staff turnover, average wages and number of employees in form P-4;

- report on identifying employees of different qualifications;

- information on observations of labor use;

- data on the level of labor costs, as well as information on their reduction.

The study determines indicators of the number of employees, staff turnover, their social protection, rational use of labor and working time, as well as labor productivity.

Analysis of the use of labor resources helps to solve two main problems: the rational use of labor, as well as increasing production volumes.

What indicators are assessed?

Analysis of the use of labor resources helps to evaluate several indicators:

- the presence of a sufficient number of appropriately qualified employees at the enterprise;

- measures aimed at social protection of company employees;

- rational use of working time;

- level of labor costs for production;

- volume of production.

The calculation of each indicator is important for finding measures to improve and optimize the work process.

What coefficients are calculated

In the process of analyzing labor resources, a number of coefficients are calculated that show a qualitative and quantitative assessment of the use of labor:

- hiring new employees;

- dismissal of employees;

- staff turnover;

- staff stability.

Loss ratio

The loss coefficient is a symbol for the period of an employee’s work activity during the day, which characterizes his productivity.

The general formula for calculating the coefficient is as follows:

(Time to complete a task)/(Shift duration time)=K lost working time

Ideally, the calculation should yield a unit, but it is practically impossible to optimize the enterprise so much. Also, for the accuracy of the calculations, the formula is used separately to determine the loss of working time due to the fault of the employee and to determine downtime due to the fault of the employer or reasons beyond the control of the parties.

The time to complete the task is determined by the employer based on standard calculation formulas, which include various methodological studies.

What is it and its causes

According to the classic definition, losses are understood as periods of working time not spent on completing a production task or regulated breaks. The study of this topic was of greatest relevance during the Soviet period, in conditions of permanent production competitions. Then, the main reason for the phenomenon under study was considered to be the employee’s dishonest attitude towards work, manifested in such misconduct as lateness, absenteeism, extraneous activities during the shift, damage or irrational use of raw materials or equipment, etc. Currently, the approach to understanding the causes of temporary leaks has changed . This is primarily due to the emergence of new professions characterized by the complexity and variety of work functions and, as a consequence, multitasking. In addition, at many enterprises there is unevenness in the receipt of orders, which leads to an uneven workload for personnel at all levels.

Calculation of lost working time

The coefficient of lost working time is calculated using the general formula presented above. However, in a situation with violation of labor discipline, a different method of calculation is used.

To calculate the loss coefficient in case of violation of labor discipline conditions, the following formula is used:

(Time of violation of labor discipline)/(Total shift time)=K losses

To calculate the total loss factor using both formulas, the following formula is used:

((B1+B2)+(In department - In reg. department))/(Shift duration)×100=Total loss coefficient

Where:

- B1 – time lost when completing a task;

- B2 – loss of time due to violation of discipline;

- In the department – time actually spent on rest;

- In reg. dept. – regulated rest time in accordance with labor legislation and the contract.

To determine the total duration of loss of all employees of the organization, the following formula is used:

(Hours per year - Hours of employees)×Number of employees

Where:

- hours per year is the total number of hours of work per year that all employees of the enterprise worked;

- employee hours – working hours of one employee.

The calculation is made taking into account the planned and actual determination of lost working time, and then the resulting indicators are compared.

What it is?

The time allotted for the performance of an employee’s direct duties can be divided into a productive and irrational part. The first includes the period of creation of an economic product and regulated pauses.

Lost working time at an enterprise is considered to be intervals spent on activities that do not provide an increase in the quantity of goods or an improvement in their properties.

In addition, this includes unauthorized interruptions due to a violation of the sequence of technological operations due to a failure or neglect of established standards of behavior.

Recommendations on how to account for working hours

To record working time, it is proposed to use timesheets, since they can be used to track the performance dynamics of each employee individually and the enterprise as a whole.

You can mark the duration of working hours to account for losses as follows:

- The duration of employees’ stay at the workplace, as well as all the reasons why they did not show up for work or were late for it using a report card established by law.

- By recording only no-shows.

- By keeping records of the daily, weekly and cumulative loss of time by each employee individually or by the general work collective.

The accounting period is calculated based on the employer's needs, but cannot exceed more than one year.

Estimation and calculation methods

An important indicator of the use of the interval allocated for the implementation of labor functions is its balance.

Formula

Let's consider the structure of this parameter relative to the activities of one employee during the year:

- calendar fund (FC) is the number of days in the billing period, which includes all holidays and weekends (PV);

- nominal reserve (FN) is defined as the difference between FC and PV;

- useful component (FP) is calculated by the formula: FN - N, where N is the number of no-shows;

- to calculate FP in hours, you need to substitute the corresponding values into the expression: FP * (PPD - PR), where PPD is the planned duration of the shift, and PR is the costs associated with reducing the working day.

Coefficient

The indicator of rational use of the labor measure (CI) is the result of division:

KI = ROTR - RPOTR, where ROTR is the actual number of hours or days worked, and RPOTR is the planned number. The best result is CI = 1.

Analysis methods

To measure labor, various techniques and types of observations are used. They can be classified according to several criteria.

Research methods:

- direct measurements;

- momentary.

Purpose of study:

- timing;

- photographic timing;

- photo.

Monitoring tools:

- visual;

- automatic;

- special devices.

Principle of data recording:

- digital;

- index;

- graphic;

- photo, film recording;

- mixed.

Timing

This is a way to study a separate labor procedure or its components. The time spent on completing each element from a list compiled in advance is measured and recorded. For accurate counting, use a stopwatch.

Objectives of the test:

- set cost standards;

- checking applied standards;

- studying employee techniques with the best results.

Working day photo

It is used to study the costs of labor measures and organize loss management. Observations are made according to the current time, all results are recorded. The photographing process is not interrupted until it is completed.

Purpose of the event:

- determine the degree of efficiency of using the gap;

- balance sheet rationalization;

- comparison of actual and possible staff load.

Photochronometry

Analysis of the structure of working time costs throughout the day, using different methods (photography or timing) for individual elements of the procedure.

Momentary Observation Method

This is the recording and accounting of expenses of the same name at randomly selected points. The method is based on the law of large numbers. He argues that the whole can with high probability be judged by its part.

How are they paid?

In some cases, the employee is entitled to a monetary reward, even if he did not produce the established norm or did not complete the task at all.

Paid losses include:

- failure to perform official duties due to the fault of the employee or his management;

- downtime due to the employer’s miscalculations or for a reason independent of the behavior of each party.

How is remuneration made when accounting for working hours? Read about this in our article.

What are the working hours for pregnant women? Answer - .

What are the rights of an employee when fired for absenteeism? See.

Stages of analyzing the use of labor resources

Analysis of the use of labor resources is divided into several stages. Each of them is associated with the calculation of indicators characterizing the dependence of production volume on personnel. Computations help identify ways to improve the use of labor resources.

Analysis of the supply, composition and dynamics of labor resources

The analysis of the use of labor resources begins with determining whether the enterprise has a sufficient number of employees of a certain specialty, occupying the appropriate positions and having work skills. To do this, the indicator of the base period, most often last year, is compared with the indicators of the current period.

An important task of the analysis is the distribution of employees according to the following characteristics:

- floor;

- profession, specialty, qualification;

- level of training, position held;

- availability of skills and overall work experience at the enterprise.

To analyze the supply, composition and dynamics of labor resources, it is necessary to compile a table.

| Indicator for analysis | Planned | Base period | Current period | Deviations from the plan | |||

| In people | Specific gravity, % | In people | Specific gravity, % | In people | Specific gravity, % | V % | |

| Total number of employees | 50 | 100 | 45 | 100 | 45 | 100 | – 11 |

| Production employees | 30 | 60 | 28 | 62,2 | 32 | 64 | 6,7 |

| General workers | 15 | 30 | 11 | 24,4 | 10 | 22,2 | 20 |

| Management | 1 | 2 | 1 | 2,22 | 1 | 2,22 | 0 |

| Employees performing job duties not related to production | 4 | 8 | 5 | 11,1 | 2 | 4,44 | – 50 |

Important!

The main factor in increasing production volume, and therefore the profit of the enterprise, is the presence of a sufficient number of employees in certain specialties.

Average wage category of workers (formula)

The average salary category of employees summarizes the assessment of the enterprise. In its own way, it is an average indicator of the use of labor resources. To calculate it, use the formula:

STR = (TR * KR) / KR

, Where

STR – average tariff category;

TR – tariff category;

KR – number of employees of the calculated tariff category.

In addition to the STP, the average tariff category of work (hereinafter referred to as STP) is determined, which is also calculated using the formula:

STRR = (TPP * Chr) / Chr,

Where

TRR – tariff category of work;

CR – the number of completed works of the calculated tariff.

Turnover coefficient for hiring workers (formula)

You can study the employment rate of new employees by calculating the turnover coefficient for their admission (Cobr). The calculation consists of finding the relationship between the number of newly employed citizens (KPR) and the average number of working people (AFR). It is much easier to calculate using the formula:

Cobr = Kpr / SChr.

Disposal turnover ratio (formula)

The attrition turnover ratio (Row) characterizes the level of layoffs occurring in the company. It is calculated by the formula:

Kov = Kur / SChr , where

Kur – the number of dismissed employees of the enterprise for the calculated period;

SChr – average number of working employees.

Employee turnover rate (formula)

An increase in the staff turnover rate (KTR) shows the negative impact of certain factors on the economic activity of the enterprise. The thing is that frequent changes of personnel lead to a decrease in production volumes. After all, it will take time before a new employee learns to perfectly perform the assigned job.

Ktr is calculated using the formula:

Ktr = (Kur / SChr) * 100%.

Coefficient of constancy of the enterprise personnel composition (formula)

The coefficient of personnel constancy (Kpsk) shows the unchanged part of the personnel by qualifications during the calculated period. It is determined using the formula:

Kpsk = Kpr / SChr , where

Kpr – the number of permanently working employees in the reporting period;

Average headcount

The average number of employees (Avg) shows the average number of workers at the enterprise. The indicator is determined by the formula:

Chr = (Kyar * Chrd + Cho) / Chrd

, Where

Kyar – the number of employees who appeared in the reporting period,

Chrd – the number of working days in the calculated period;

Cho – number of absent employees.

Reserve for increasing production output by creating additional jobs

The calculation of this indicator is necessary to determine ways to increase production volume by employing new workers. It is calculated using the formula:

Ruop = Snrm * Vsg , where

Rupop – reserve for increasing production volumes;

Snrm – creation of additional jobs;

Vsg – the number of products produced per worker per year.

Analysis of social protection of workers

An analysis of the social security of workers at an enterprise is carried out in order to determine the dependence of the level of well-being of workers on the measures taken by the company to protect them. During the research, the following possibilities are identified:

- retraining of employees, thereby increasing their qualifications;

- introduction of measures aimed at improving working conditions;

- employee health improvement;

- organization of cultural life at the enterprise;

- improving the living conditions of workers;

- protection of all workers at the enterprise in social terms.

Dynamics and implementation of the plan to improve the skills of employees

During the analysis, current, planned and baseline indicators are compared. First of all, the percentage ratio of the average number of employees to:

- the number of employees undergoing retraining or who have already received additional qualifications;

- to the number of unqualified employees.

Evaluation of measures to improve working conditions and improve the health of workers

To study this indicator, the following variables are assessed:

- Number of premises intended for sanitary and domestic needs. It is necessary to determine their sufficiency.

- Carrying out hygiene procedures at the enterprise. For example, the presence of showers, sinks, hygiene products, etc.

- Determination of the percentage of injuries that occurred at the enterprise during the reporting period. For the calculation we take 100 people.

- The number of workers suffering from various diseases. In this case, illnesses arising in connection with the performance of work duties are taken into account. Otherwise they are called professional.

- The number of people on sick leave during the study period per 100 employees.

- Number of personnel undergoing rehabilitation at the expense of the enterprise. This also includes employees vacationing on vouchers purchased with company funds.

- Assessment of measures aimed at creating fire and labor safety.

Social, cultural and living conditions of workers and their families

This indicator is assessed by identifying the following variables:

- number of employees who have their own real estate;

- comparison of planned indicators with actual indicators for the construction of housing for staff;

- assessment of the availability within walking distance of communications, cultural and leisure centers, as well as hospitals, schools, kindergartens, etc.

Social security of members of the workforce

Social protection of personnel consists of providing material support, for example, for the purchase of housing, treatment, for major family events (birth of a child, wedding), etc.

Analysis of the use of working time fund (working time fund, influencing factors, formula)

The working time fund is a qualitative indicator of the use of labor. It includes:

- the number of employees actually engaged in labor duties in the calculated period;

- the number of employees working outside the norms established by the enterprise (not full time, overtime, on holidays, etc.).

The dynamics of the working time fund are influenced by several factors:

- the average number of employees at the enterprise;

- number of days in the calculated period;

- number of working hours in a day.

The working time fund is calculated using the formula:

SChT * KDrp * ChRchs

, Where

SNT – average number of employees at the enterprise;

KDrp – number of days in the calculated period;

HRchs – the number of working hours in a day.

Coefficients expressing the qualitative characteristics of the use of working time

In the process of analysis, the rational use of working time is revealed by assessing its characteristics. In this case, the coefficients are calculated separately:

- finding the relationship between the number of days worked by one employee and planned or baseline indicators helps to understand the use of working time by a particular employee;

- identifying the relationship between the actual duration of a work shift and the planned one helps to understand the degree of day utilization.

In addition, the full coefficient of employees' use of their working time is determined. Calculations are made according to the formula:

KiV = Thebes/Pis

, Where

KiV time utilization factor;

Thebes – time actually used;

Pis – time used according to plan or in the base period.

Reducing lost working time (calculation formula)

To calculate this indicator, the formula is used:

SPrv = Strv * Op1ch

, Where

Strv – average loss of working time;

Op1h – production volume per hour.

Labor productivity analysis

Labor productivity analysis is carried out to identify the efficiency of labor use.

Product output per employee per period of time (formula)

To find out how many products one worker produced in a certain period of time, you need to divide the number of finished goods by the amount of time spent.

Op/Chw,

Where

Op – the volume of goods produced by one employee over a certain period of time in pieces;

Chv – the number of hours, days for production of products by one worker.

Average annual production per employee (formula)

An employee's average annual output directly depends on the number of shifts he works, the number of days he is absent, and the average length of the shift.

The indicator is determined by the formula:

SGv = Uv * Chod * Ps * Opch,

Where

Uv – share of employee;

Chod – the number of shifts worked by the employee;

Ps – average shift time;

Vpch is the volume of production by one employee per hour.

Reserves for increasing average hourly output (formula)

The reserve for increasing average hourly output (Ruschv) is determined by the formulas:

Ruop = Snrm * Vsg,

Where

Rupop – reserve for increasing production volumes;

Snrm – creation of additional jobs;

Vsg – the number of products produced per worker per year.

Ruschv =

Ruop * FRV, where

FRV is the total working time according to the plan.

Assessing the efficiency of using labor resources (calculating the indicator)

To assess the efficiency of using labor resources, several indicators are multiplied:

- the average number of employees working at the enterprise;

- number of days worked by one employee;

- average working time per day.

Example 1.

The company employs on average 150 people. One employee worked 200 shifts per year. The average shift length is 12 hours. It is necessary to evaluate the effectiveness of the use of labor resources.

150 * 200 * 12 = 360000.

Analysis of the use of the wage fund

Analysis of the use of the wage fund evaluates the rationality of the costs of paying employees' wages. In this case, the actual number of products produced is examined.

Absolute and relative deviation of the actual size of the wage fund from the planned one (calculation formulas)

To find the absolute deviation of wages (Ao), it is necessary to subtract the planned one (Pop) from the Actual wage fund (Fop):

Fop – Pop.

To calculate the relative indicator, the planned fund is subtracted from the amount of accrued wages for all employees. A more accurate estimate can be obtained by calculating using the formula:

OO = Fop – (Fop * Pvp + Foppr),

Where

OO – relative deviation from the plan;

FOP – actual salary fund;

Pvp – indicator of fulfillment of production volumes according to plan;

Foppr, Fopp – planned salary fund (its variable and constant, respectively).

Percentage of increase in the planned wage fund by 1% of exceeding the production plan (formula)

To understand how much employees’ salaries can be increased for exceeding the plan, it is necessary to calculate possible deviations in the formation of the wage fund.

The planned indicator is calculated using the formula:

Fop1 * (100 + Pp * Pk

), Where

Fop1 – salary fund according to plan,

Pp – exceeding planned targets in %;

PC – correction factor.

How to Determine Payroll Savings

To determine savings or, conversely, overexpenditure of the wage fund, it is necessary to find a general indicator calculated using the formula:

Fop * (ZPis – Ppi) / ZPis

), Where

Fop – actual wage fund;

ZPis – average salary at the enterprise (its index);

Ppi – labor productivity (its index).

Product labor intensity analysis

Labor intensity refers to the cost of working time to produce one product or all goods. The indicator is calculated using the formulas:

FV1/Kpp, FV1/Spp,

Where

FWF – working time fund;

KPP – quantity of products produced;

CPP is the total cost of manufactured products.

Types of losses.

Currently, there are eight main types of losses:

Overproduction

Excessive production takes away the company's working capital and freezes it. To value it in money, look at what is in the warehouse with different eyes. Convert this into money and deposit it in the bank - this will be the minimum amount of your losses. The same applies to information, databases, etc.

Lost time due to waiting.

In this type of loss, I think everything is clear. The soldier is sleeping, the service is going on, and the money is dripping.

If you say that we are all on a deal, let them drip, you still have to pay based on the work completed. That’s all true, but you will also receive profit later and in a smaller volume. And the team will be able to produce less volume, which will also reduce profits.

Transportation.

There are no difficulties in perception of this type of loss either. Treat any movement of product, raw materials, or resources as losses. For example, moving a pallet of materials around a warehouse is a waste. Yes, there are necessary movements, but you should always think about how to minimize them. Moving the product by conveyors also applies to this type of loss. Pay attention to all possible intermediate storage buffers; everything in them is losses. I, as a buyer, will not pay you for these movements. This will also fall into your company’s cost budget.

Overprocessing

This type of loss is not as obvious as the previous ones. Especially when you hear: “we’ve always done it this way and there were no questions.” As soon as you hear these words, you can safely roll up your sleeves, you have entered an unplowed field. The simplest example is that in order to make a product 10x10x10 cm, a machine operator is given a workpiece 20x20x20 cm. In addition, more than half of the material will go to waste (for which the company will again pay). So you will have to work with it much longer than if the workpiece were 11x11x11, or the supplier immediately supplied 10x10x10. Or another example from life. You are sewing a button on 6 ties, but it will hold just as well on 5 ties. 1 screed is a loss.

Over-processing is common in the struggle for quality. But here you need to find a balance and do what the Consumer is willing to pay for. One of the methods for finding balance is the Pareto Principle. When you choose 20% of the key parameters that will ensure 80% of success.

Inventories (tops loss types in popularity)

Our “favorite” type of loss. After all, “the reserve is not enough.” Is it true? Very similar to the first type of loss, but at the beginning and during the production process. And if stocks have an expiration date, then losses increase even more.

Movements

Similar to transportation losses, but of personnel. Every possible trip in search of parts and tools. In the office, trips to offices for approvals, which turn into get-togethers, etc.

Marriage

Probably the easiest to understand. Defective products are costs in themselves, but other types of losses are added: transportation, processing, excessive control.

Potential

The most difficult to evaluate, but key in the development of the company. People work within the framework of the system that is installed in the company. And if the employee’s voice is not heard, then the company is not using his potential. For example: to perform some work you need to rearrange the machine. This will give an increase in quality, productivity and a lot of other good things. The specialist reports this information to the foreman, the foreman reports this information to the head of the section, the head of the section did not dare to tell this to the head of the workshop, and then forgot. That's it, the company didn't make a profit.

How to calculate working time utilization rate

Home - Business Organization - Personnel - The utilization rate of the working period is an important indicator of productivity. It will be useful for the manager of any business entity to determine this indicator for himself or his employees in order to fully understand where working time is spent, how productive it is spent, and what kind of return comes from it.

Contents: 1. Working time funds 2. Coefficient of working time use - concept 3. The benefits of calculating the working time coefficient 4. Coefficient of working time use - formula 5. Calculation of the working time coefficient 6. Coefficient of lost working time 7. Analysis of spent time Working time funds In calculating the coefficient, an important role is played by working time funds - methods of calculating available and potential time spent on work.

The following types are distinguished: The calendar fund is the sum of days for which during the reporting period the employee showed up (or did not show up) for work. If we take a year as the reporting period, then the calendar time fund is 365 days per employee. Let's say a company employs one hundred people.

The total calendar fund is 36,500 conventional units. Man-days are used as a conventional unit for calculating the fund.

This time fund allows you to determine the number of employees on the payroll, as well as establish the available and required number of man-days. The time fund is a more specific indicator, since its calculation does not take into account weekends and holidays.

This is the sum of payroll days for a conditionally taken reporting period. That is, if you subtract weekends and holidays from the calendar fund, you can get a time fund.

The maximum possible fund is a universal indicator that needs to be calculated in order to understand the maximum number of conventional units that can be worked out in a particular period of time.