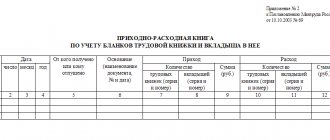

Any company that uses hired labor is required to keep records of work records. This accounting is kept in special accounting books according to the relevant rules (they are described in the Rules for maintaining and storing work books (No. 225), paragraph 41). Violation of the Rules entails penalties against the organization. By the way, it is the procedure for maintaining the Employment Logbook that primarily attracts the attention of auditors and other inspectors. In this article we will tell you how to seal the work record book and give step-by-step instructions.

Rules of law

A work book is the most important document of an employee, the safety of which is controlled by the employer. By law, if a company has at least one hired employee, it is necessary to keep a log of work records. This is a legal requirement, which is stated in the rules for maintaining and storing TC. Moreover, such a record book must be sealed in accordance with the law. This is a document of increased accountability, therefore, its appearance and sealing, in particular, should be treated with extreme care. This measure helps protect the journal from external interference in order to make adjustments to existing records.

Sealing (protection) of the work record book is an important aspect of the HR officer’s activity. This document is always checked during scheduled visits by specialists from the State Labor Inspectorate. Disadvantages in the design of such forms are discovered very often.

There are certain requirements regarding the appearance and size of the magazine, including:

- The book must be in A-4 format.

- Its volume (number of sheets) should be such that it is enough for at least 2-3 years.

- Thick cover. It is needed because the work record book is used for a long period, and is stored in the archive for even longer.

- The layout of the pages should be such that all the necessary data can be entered.

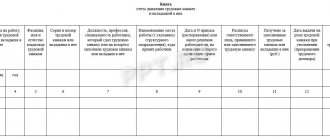

Other important requirements for the book of accounting for the movement of work books and inserts in them:

- The journal must be signed personally by the manager.

- Each sheet is hand numbered by an authorized employee.

- The book must be stitched and sealed.

If at least one of these requirements is not met, this will lead to the imposition of penalties on the employer.

Sealing

There are no special requirements for the firmware and sealing process.

Personnel workers or accountants keeping records of records themselves choose the option of carrying out the procedure. They are based on the Rules for maintaining and storing work books, approved by the Government of the Russian Federation dated April 16, 2003 No. 225, which in paragraphs 40-41 indicate that the accounting journal should be:

- numbered;

- stitched;

- signed by the head of the organization.

Download rule No. 225 “On maintaining, storing and filling out work books”

After proper preparation, the magazine must be sealed with a wax seal or sealed. Recently, sealing has become the most important, since wax seals are not strong enough and the material for them (waxing wax) has lost its popularity.

The seal can have different varieties, which can be dictated by the list approved for the types of sealing devices. They are approved by the Rules of GOST 31282-2004. These include means of possible identification of one-time use, which are capable of protecting against unauthorized opening of the protected object.

Download Sealing Rules GOST 31282-2004

The most relevant are film seals, which can only be used in office work, since they do not have the power of deterrence, but only identify the absence (presence) of intrusion.

They are quite convenient and have the appearance of a flat multilayer film, quite dense and made in the shape of a small circle or other figure. It is desirable that it resemble a seal not only in shape, but also in properties. To do this, it must be provided:

- unique number;

- organization logo;

- name of the organization.

Since the requirement is only for the presence of the seal, and not for its quality, the manager or authorized person can show his imagination.

You can use a more durable material, even using a lead plate, and you can also choose the code identifier at your discretion. It is possible to provide the seal with electronic memory. If desired, you can use a wax seal instead of a filling.

Sealing a magazine - attaching a seal to its rear inner wall. The seal should be attached to the ends of the thread or cord used to stitch the magazine. Properly attached, it, together with the tip of the thread, is attached to the magazine cover in the designated place, simultaneously capturing:

- A piece of paper that was used to attach (glue) the thread to the cover of the magazine.

- The part of the cover outside the pasted paper.

Thus, a protection is formed, which consists of simultaneously bonding the thread, the printed paper and the magazine cover. The ID will show if records have been tampered with. In this case, you will have to tear off the piece of paper that secured the thread and remove the seal, which will be immediately detected by the employee authorized to keep the journal.

When using a wax seal, you need to melt the wax, pour it into a certain place on the inside of the cover, simultaneously capturing the lacing, part of the sheet and part of the cover.

Before the sealing wax has time to cool, you need to put a special imprint on it. It is the absence of an impression, which is prepared specifically for sealing, that becomes the reason for the unpopularity of using a wax seal and the preference for using a seal.

After the stitched Accounting Book is sealed or sealed, it can be used to enter the necessary information.

In the absence of sealing, the head of the organization or private entrepreneur will be fined by a commission from the labor inspectorate.

Everything you need to know about magazine firmware

Before flashing a magazine, you need to familiarize yourself with the legal requirements regarding this process. The first stage is its weaving, which is necessary if the magazine is thin. Its thickness may be enough for many more records, but if the cover wears out, it can no longer be used. As a result, after each inspection a fine awaits.

The next step is filling out the title page. According to the rules, you must number the pages. The order of this is extremely simple - end-to-end, that is, each subsequent page has a number one more than the previous one - 1, 2, 3, 4, 5, etc. A failure in numbering or a number of pages less than stated is also a fine for the manager.

Why do you need a work record book?

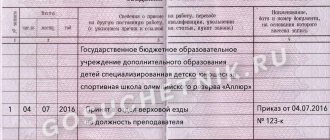

According to the Labor Code of the Russian Federation, the shelf life of this Book is 75 years; such a long period is provided for by the peculiarities of the information contained in it. In the Book you can find out about the receipt and issuance of work books, information about the position of their owners, the department in which their work took place, the date of hiring the employee and the date of his dismissal, and so on.

According to one of the main requirements specified in the Rules, this Book of Work Records must be sealed. Some specialists responsible for this do not know how to do it correctly - this will be discussed in this article, as well as the filling algorithm, fines, regulatory framework and responsible persons.

Materials for firmware

In order to lace a book, which is also a mandatory requirement, you need:

- An awl is a very strong knitting needle with a pointed end. Something like a thick needle without an eye. Due to the comfortable handle, it is possible to penetrate the thickness of the paper in almost one movement.

- Threads (twine) used to stitch the magazine. They must be strong, but at the same time flexible. Excellent solution LSh-20. This thread is strong and soft, and is easy to work with when stitching documents. Sometimes, due to lack of resources, they stitch the magazine with ordinary thread No. 10, but this is not very convenient and not very durable, so it is better to buy suitable ones once. In addition, such threads easily tear the paper, which is a violation in itself.

- Needle, crochet hook - for threading.

- Possibly a hole punch, but they need to penetrate the entire thickness of the magazine and the cover.

In order to make the tip of the thread more rigid, you can lubricate it with nail polish or office glue. After completing the process, be sure to cut off this section of the thread.

How to properly stitch documents with threads in 2, 3 and 4 holes: diagram, photo and video instructions

» Business organization » Registration » Office work » How to hem documents with threads for 2, 3 and 4 holes, as well as on the corner

Documents are stapled to ensure their integrity. Sequential numbering, as well as fastening the sheets with lace or thread, completely solve this problem.

Sometimes lacing is necessary according to the rules established by the organization, sometimes - according to the law. In this article we will look at how to properly flash documents in office work.

What documents need to be stapled?

In office work, documentation is most often stapled in order to transfer it to the archive, or when submitting it to a bank and other financial institutions. Also, document firmware is required when submitting reports to extra-budgetary funds and the Federal Tax Service. The document must not only be stitched, but also numbered. Papers are sewn together either with thread or tape, or using special machines.

The following types of documentation are subject to firmware:

- orders (both general and personal);

- staffing schedule;

- reports (for example, expense report);

- invoices;

- acts of completed work;

- cash book;

- statements.

It is also necessary to stitch documentation sheets when submitting an application for participation in a tender and in other cases.

— how to stitch things together before putting them into the archives:

Regulatory acts

The regulatory framework that today regulates the procedure for flashing documentation is very broad, however, most of the regulations have not been updated for a long time.

Thus, the main act that regulates the process of firmware documentation is the order of the Ministry of the Russian Federation for Taxes and Duties dated April 18, 2003, containing general instructions for filling out certain types of papers, including their firmware.

In addition to this document, the following regulations can be distinguished:

- GOST R 51141-98 “Office management and archiving. Terms and Definitions".

- Order of the Federal Tax Service of January 25, 2012 N ММВ-7-6/25. According to this order, the mandatory binding of documentation when submitting documents for registration of an organization or individual entrepreneur is canceled, however, the Federal Tax Service still prefers to accept stitched sheets.

- how to file things correctly:

Firmware documentation in some areas of activity is regulated by separate regulations of the organizations responsible for the area. Thus, firmware in the banking sector is regulated by the Instruction of the Central Bank of the Russian Federation “On office work in the Central Bank of the Russian Federation.”

Requirements for government agencies

The requirements for submitting documentation to government agencies differ from the requirements for documents when submitting, for example, to an archive. So, in order to submit papers to the court or tax office, you must follow the rules below:

- documents must be fastened in 3 holes;

- the distance between punctures should not exceed 3 cm;

- the paper is sewn together with thread or thin twine;

- paper measuring 3x5 cm is glued to the last page, on which a certification signature and seal are placed.

Special requirements apply to accounting reports, and the knot on the last page must be sealed with tissue paper.

How to flash documents correctly

Documents can be stitched with thread, lace or ribbon. This process must be approached responsibly, because if the firmware is of poor quality or weak, then the papers can be easily separated, which should not be allowed, because they are stitched so that it is impossible to put another document on them or lose part of it.

Moreover, if you are stitching papers for submission to government agencies, then incorrectly completed firmware can lead to the fact that the Federal Tax Service, extra-budgetary funds or the court simply refuse to accept them.

In 2 punctures

Firmware with 2 holes is very simple. Holes can be made either with a needle or with a hole punch. Of course, it's easier to pass thread, ribbon or string through the holes made with a hole punch.

The punctures should be on the left edge of the sheet (like a regular book) approximately 1-2 cm from it. After you pierce the paper, you need to pass the thread through the hole several times and tie the ends of the thread with a knot on the last page.

, which shows how documents are sewn together with threads through 2 holes:

In the upper right corner of each sheet you need to put the page number.

After this, the stitched documentation must be secured by gluing 3x5 cm paper onto the ends of the thread so that the ends peek out from under it. The paper is marked “Stitched and numbered” and the number of pages is also indicated. Afterwards, depending on where the papers will be provided, details such as the official’s signature, seal, and date are placed on the paper.

For 3 holes

Things are somewhat more complicated with stitching with three punctures, especially if you immediately pierce the sheets with a thread and a needle, rather than using a hole punch. To sew three holes on paper, follow the step-by-step instructions below with the diagram:

- Make the first puncture with a needle and thread on the back of the document being stitched in the middle of the sheet

- The second puncture with a needle is made on the front side of the document

- The next puncture should be made from the back of the third hole

- In the next step, we pass the needle and thread through the first hole - in the middle of the document on the front side

- Then you should tighten the threads so that they tightly pull the stitched sheets together and tie a knot as shown in the photo

clearly explains how to sew documents with 3 holes:

For 4 holes

This type of firmware is done only for documents that have a special status of importance.

To sew documentation into 4 holes, follow the following diagram and step-by-step instructions:

If the document being stapled contains many sheets, then you can pre-prepare four holes using a hole punch, drill or a special machine.

- You should start threading from the back side of the second hole from the edge.

- Next, the thread is threaded into the hole that is closest to the edge and the previously passed hole.

- Then we thread the thread again in the same way as in the first step.

- Next - from the front side to the next hole

- In the extreme puncture on the back side

- From the front side of the hole that we passed in the fourth step

- At the same time, we try to pull the thread so that it tightly compresses the sheets of documents

- All that remains is to tie the thread in a knot

- Trim excess length of thread ends

If the documents have been stitched correctly, all that remains is to number the sheets and stick a piece of paper on top of the bundle with the inscription “Stitched, numbered and sealed by ______ ( _____________ ) sheets” and put down the necessary details of the certifier (position, signature and full name).

— how to sew a case with 4 holes:

To the corner

Some papers may be corner bound, i.e. in the upper left corner. To do this, you need to make one or two holes in the corner and pass the thread through them several times.

— an example of stitching documents through a corner:

A sheet of paper, as in other cases, is glued to a knot of thread, and the details necessary for certification are placed on it.

How to number sheets

In most cases, numbering sheets when stitching does not cause difficulties, however, it is necessary to take into account some nuances:

- most often page numbers are written in Arabic numerals in ascending order;

- The sheet number is indicated at the top right. The number should not overlap the contents of the sheet;

- if there are applications, then they must also be numbered (continuous numbering is used);

- if letters with envelopes are attached to the documentation, then first of all the number is placed on the envelope, and then only on the sheets of the letter;

- if you number a case in which there are several volumes, then each of them is numbered separately;

- If it is necessary to number a sheet of a non-standard format, the number is also placed in the upper right corner. If the sheet extends beyond the document, it is folded and filed in the general manner;

- if the sheet contains several scans of small fragments (for example, checks), then it is recommended to create an inventory for the sheet and attach it to the documentation package, numbering it in the general order.

How to certify a bound document

After stitching and numbering of sheets, the documentation package must be certified. To certify it, paper is glued to the thread knot on the back side so as to leave the very ends of the thread free.

On the paper you must indicate the number of sheets (both in numbers and in words). If the bound document contains torn or damaged pages, this can also be indicated on the certification paper.

Next, it indicates the name, position and signature of the person who stitched the sheets or certified them (for example, a manager). A seal is placed on top of the paper so that its imprint is on both the certification paper and the last sheet.

You can download the sample “Stitched, numbered and sealed” in Word - HERE.

Corrections

When updating the firmware, the clerk may make a number of errors, which, fortunately, can be corrected. Let's look at the most common of them:

- Some papers were not included . It happens that the clerk did not attach some part of it to an already bound document. In this case, there are two solutions: you can file the missing part as a separate volume, or you can reflash the document again. Under no circumstances should you simply insert the missing part into an already stitched package of papers;

- There was a mistake in the numbering . If a leaf is missing in the numbering, then you can resort to literary numbering, that is, write a letter after the number, for example, 14, 15, 15a, 16... If serious errors are made in the numbering, then you can cross out the incorrect numbers and write them again. If the number of sheets indicated on the certification paper is incorrect, then the number of sheets in it must also be corrected to the correct number.

Firmware of documents is needed in order to exclude the possibility of substituting or inserting sheets into it. Depending on the importance of the document, it can be stitched in 2, 3 or even 4 holes. After stitching, the sheets are numbered and a certification paper is attached to the unit indicating the number of sheets and the name of the witness. A stamp, date and other necessary details are placed on top of the paper.

— firmware of documents for the archive and production of hard cover:

Source: https://delat-delo.ru/organizatsiya-biznesa/oformlenie/deloproizvodstvo/kak-proshit-dokumenty.html

Stitching order

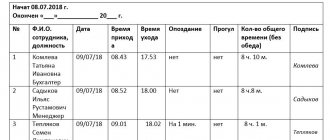

There are clear regulations on how the firmware for the registration and accounting log should look. In order to comply with everything, you need to follow this algorithm:

- Sewn on the left side of the magazine margin.

- To do this, there must be 3 holes at an equal distance from one another relative to the middle of the sheet. There is no standard for the distance, but experienced personnel officers recommend making it within 5-7 cm from the central hole.

- The thread is started from the back and pulled forward through the outer holes.

- Now you need to align and connect them, thread them through the central hole and pull them out onto the front of the cover from the back.

- If the thread is thin (for example, No. 10), then this process must be repeated several times. In this case, each “circle” should be checked for the evenness of the thread and its shape.

- The last stage is tying the threads into a knot. When tying, you also need to grab the central thread.

How to staple documents?

Only authorized employees should stitch documents using special threads (bank twine, LSh-210 threads) and needles. In order to stitch documents (this must be done so that the file can be read if necessary), three holes are made with an awl on the left margin (about 1.5 centimeters from the text), one above the other: the central one should be exactly in the middle, and the distance between The central and upper (lower) punctures should be three centimeters. If the case is multi-page, then it is more convenient to make punctures with an awl, but for more delicate cases you can use a hole punch. To prevent mechanical damage to the first and last sheets of the case, it is better to glue thin strips of cardboard at the stitching site through which the thread will be passed. To stitch documents you will need a thread approximately seventy centimeters long.

For convenience of explanation, we will conditionally number the punctures: No. 1 – upper, No. 2 – central, No. 3 – lower. You need to start by threading the needle into hole No. 2, leaving one end of the thread on the back side of the stitching. After this, we pass the needle from the front side into hole No. 1. As soon as the end of the thread and the needle are on the back of the case, you need to bring the needle to the front side through hole No. 3, and then again to the back side through hole No. 2. The case is stitched through all three holes, and now you can tie a knot on the back. The knot is tied very tightly, as close as possible to the last sheet and is fixed with glue and a certification sticker. In this case, the ends of the thread should be free and visible.

Design of a sheet for fastening threads

In order to prepare the magazine for sealing, you need to perform one more stage of work - glue the threads to the magazine. This process has a number of features. Execution order:

- Pull the threads tightly.

- Fold over the edge of the cover.

- Glue. The gluing itself is carried out using a piece of paper designed in a certain way.

Form for gluing:

- Cut out a square measuring 8x8 cm from regular office paper.

- Write the phrase “the magazine is stitched”, be sure to indicate the date using Arabic numerals.

- Get the manager's signature on it.

- Glue the sheet to the inside back of the magazine by passing a thread through it. Do not trim the edge either.

- Place the organization's seal so that it appears on both the glued sheet and the journal sheet. This point is important, because such protection will allow you to immediately see whether any actions were taken with the primary filling.

This sheet is an important element of subsequent filling.

How to number sheets?

When numbering sheets, you should remember several rules:

- It is the sheets, not the pages, that are numbered;

- the inventory is not subject to numbering;

- if there are letters in a bundle of documents, the envelope itself is numbered first, and then all the enclosed sheets are numbered one by one;

- numbers should be placed in the upper right corner of each sheet, without touching the text of the documents;

- numbering is performed in ascending order using Arabic numerals;

- if the case consists of several volumes, then numbering is performed separately for each volume, and appendices to cases, which are issued in the form of independent volumes, are also numbered separately;

- if the case contains documents from several sheets that have their own numbering (including printed publications), they should still be numbered in the general order;

- sheets of large formats - A2, A3 - must be unfolded and numbered in the upper right corner, and then hemmed at one edge;

- a sheet with tightly glued fragments (checks, delivery notes, newspaper clippings, extracts, photographs) is numbered as one sheet, but on its back or at the bottom (if there is space) it is necessary to make a handwritten inventory of the glued documents, while in the general inventory of the case in in the “Note” column or in the certification inscription, it is necessary to indicate that on sheet No. 00 such and such documents or photographs are pasted in the amount of 00 pieces according to the inventory on the back of the sheet;

- if photographs, checks, certificates are glued to the sheet only on one edge, they are numbered as separate documents in the order of case numbering;

- if the case contains diagrams, drawings or photographs, as well as other specific attachments that are an independent sheet, then they must be numbered in the upper left corner on the back;

- maps or diagrams glued together from several sheets are numbered as one sheet, and in the general inventory in the “Note” column and on the back of the card, the number of sheets in the glue should be indicated.

Sealing

Actually, this is the key process in the design of the magazine, and it was for its implementation that the above actions were carried out. The filling can be done using sealing wax or another seal. The main task of the selected tool is to block the possibility of interference in the recording.

Types of fillings

They are power and control. Each of these types has its own purpose. Lead ones are called power ones, because to remove them you need to use significant force. These are used for sealing the accounting and movement log in exceptional situations.

For such a case, a control seal is convenient; it is similar to wax and lead, but does not have the same resistance force. Its main task is to detect the fact of interference with the integrity of the log.

There are types of seals available that can be used to seal a ledger, including:

- Sticker seals. They are glued only once; if you try to tear them off, an inscription appears on it indicating interference.

- Warranty label. When you try to peel them off, they are destroyed, which is impossible not to notice.

- Tape seal. It is glued only once; if it is peeled off, the backing layer will become unusable.

The simplest solution is to seal the edges of the thread with a piece of paper and indicate the date of filling.

Seal details

Regardless of the type of filling used, it must contain the following features:

- An identification number.

- It must be disposable, without the possibility of any reuse.

- Be protected from access by forceful holding.

Step-by-step instructions: how to seal a magazine?

To seal or seal the magazine you will need:

- impression and sealing wax;

- film number seal;

- filling made of a different material.

For sealing, an impression is required, which is quite difficult to produce and requires certain costs and sealing wax. If you want to use this method of protection, which has been used for a long time, then you need:

- Melt a small amount of sealing wax.

- Carefully pour hot sealing wax onto the inside of the magazine cover in the place where the thread is secured to the sheet that was used to glue it to the cover.

- Place an impression on the wax that has not cooled down.

- Allow to cool, after which you can use.

It must be taken into account that a typo can be made inaccurately due to lack of experience and dexterity . Therefore, first try to practice on a blank sheet of paper. In addition, the wax seal may crumble before you finish using the magazine, which will lead to its unsuitable appearance.

Modern fillings are highly durable products, the fixation of which does not require much effort from you. For people who frequently perform fillings, it is advisable to have a sealer that can be used to place any fillings.

To do this, you need to take this tool, which resembles forceps, hold the ends of two threads and the material included with the kit in it simultaneously, and secure the seal. This device is easy to use.

The most budget options for fillings that can be used instead of wax seals:

- Sticker seals that you just need to stick on according to the instructions and smooth out. When you try to open it, an inscription appears on it indicating the fact of intervention.

- Warranty labels that can be simply affixed in accordance with the instructions. If opened unauthorized, they almost completely crumble.

- The adhesive seal is simply glued using the adhesive tape technology. When you try to open it, the top layer becomes unusable.

If you like to make various exclusive things with your own hands, or you can simply make a filling for free from scrap material, attach it to the tip of two threads folded together. Enter the number.

Upon completion of the sealing, a commission of at least three people must be assembled to draw up a report. Having drawn up the act, put it in the folder with local nomenclature documents.

the seal number on the inside of the magazine , have the employer sign and seal it.

Persons responsible for the magazine

An authorized employee of the HR department is responsible for all the above manipulations with the magazine and its safety. If the company is small, then directly the manager, secretary, accountant. An order is issued to grant a specific employee the authority to work with the journal. If castling occurs and another person is responsible for the accounting book, then a new order must be issued and documents are transferred. Confirmation that everything went legally will be the acceptance certificate. It must indicate:

- Information about the manager.

- Company details.

- The exact number and composition of documents to be transferred.

Choosing a magazine

Clause 7 of RD 11-05-2007 states that the magazine is printed in A4 format. That is, it means that the magazine must be purchased ready-made in a store. This is convenient for the construction of large facilities and is mandatory for facilities supervised by the inspection of the State Construction Supervision (IGSN) or the Federal Service for Environmental, Technological and Nuclear Supervision (Rostechnadzor). If the object itself is small (short construction period) and registration with IGSN and Rostechnazor is not required, then, by agreement with the Customer, the magazine can be printed on a printer.

On sale I have seen printed A4 magazines about 6mm thick with a cardboard cover and about 14mm thick with binding and hard backs like a good book. At the beginning of the journal, “Appendix No. 1 to RD-11-05-2007” is indicated.

Some nuances when keeping a journal

1. You must always know where and who has it. Superintendents, foremen, technical specialists, etc. resigning for various reasons. Engineers love to take it with them. It will be difficult to restore it. If you see that there is a lull at a construction site, people are complaining about delays in wages - take out the magazine. If possible, take out all the executive documentation. 2. Sometimes during construction they write in a draft journal (not registered), and in registered journals they write at the end of construction (or before inspections by supervisory authorities). In general, this is not correct, but some organizations require a complete absence of corrections in the journal; sometimes, when maintaining the 3rd section, they require the volume and quantity of work to be indicated as in the estimate. During long-term construction, it is difficult to track all types of work so that later the sum of volumes coincides with the estimate. Sometimes, with a large number of subcontracting organizations, it turns out that, for example, an electrical installation company, working for a whole month, completed everything - about which not a word is said in the log. If you still keep a registered account, leave an empty line after each day in the 3rd section (if someone doesn’t like the empty line, write “garbage collection” or “loading and unloading operations”). 3. Write down all the work that has to be performed that is not included in the estimate documentation. If the construction and installation contract provides for payment for additional work, these records may be useful. 4. According to clause 4 of Article 52 of the Town Planning Code of the Russian Federation, the developer (or customer) must ensure the conservation of a capital construction project, if necessary, stop work or temporarily suspend it for a period of more than six months.

The last date of work in the 3rd section, made more than 6 months ago, can serve as a “bell” for the GSN inspection to take action against the Customer.

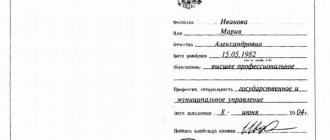

Filling out the title page

We write the name of the object correctly - with permission for construction or reconstruction. If they are not there (for example, during a major overhaul), we write the name of the object from the contract. Next, we collect copies of orders appointing responsible persons of the Developer, Customer, General Contractor, Subcontractor. We ask each of them to sign in the “signature” column. At the same time, we are collecting the details of all these organizations (you can just ask the responsible persons). Whether you have a printed magazine or a homemade one, you need to stitch it, number the sheets and seal it with the Customer’s seal. The number of pages is also indicated on the title page.