In my practice as a labor protection specialist, I have not often come across the term collective protective equipment, but when this question arose, I sometimes fell into a stupor, but what really refers to them?

And in order not to look in the eyes of management as a specialist who does not understand his own topic, I looked into it in detail and “closed” this issue. And with this article I want to help other occupational safety and health specialists who want to increase their level of knowledge, experience and find it difficult to carry out regular, similar actions and tasks.

If after reading this note you still have questions or have something to add, please join in the comments, it will be useful for other readers and the author of this note

Classification of collective protective equipment

VHCs reduce the likelihood or completely prevent personnel from being exposed to occupational factors that pose a health hazard. The products are used to normalize lighting and purify air in work areas. Every enterprise must provide protection against falls from a height, contact with electricity, and biological, chemical and mechanical influences. The temperature range suitable for the body is always maintained. Workers should not be exposed to lasers, ultrasound, vibration, noise, electric fields, as well as infrared, ionizing, electromagnetic, and ultraviolet radiation.

What to apply to collective means of protection against current

Everyone knows that without electric current it is now impossible to complete a single production task, since all work involves its use.

Double cable insulation protects against electric current

Current is dangerous to humans. To eliminate its dangerous effects, the following means are used:

| Current protection | Operating principle |

| Grounding | This is done using a wire routed into the ground. That is, it turns out that a forced connection to the ground is provided. When the voltage begins to increase, it is automatically diverted to the ground, thereby ensuring the safety of employees. |

| Zeroing | This is also a connection made between the transformer neutral and non-current-carrying parts of the device. As a rule, it is performed on all electrical installations that produce current, that is, in electrical panels. |

| Forced shutdown | All technical devices installed to convert electrical energy must have interlocking devices in case the voltage parameters exceed the norm. |

| Use of low voltages | In technological equipment it is also possible to use a low voltage indicator, namely, a device is installed that provides such an action. |

| Providing double insulation | Since wires and cables transmit electricity, they create high voltage, which poses a danger to life and health. They are insulated in two layers: if the first is damaged, the second remains intact and ensures safety. |

| Fencing device. | In technological processes where high voltage is used and for some reason it is impossible to ensure physical safety measures, protective devices are used. |

| Locking devices and alarms | They trigger as a sign of danger. |

| Safety signs, tape and posters | This is the simplest security measure. If they are posted at the production site, then workers are not allowed to visit these places. |

Air and lighting safety

Collective protective equipment includes devices for ventilation, air conditioning, deodorization, maintaining barometric pressure, alarms, and autonomous airspace control. VS for normalizing the visual environment in work areas are lighting openings, lanterns, spotlights, and protective devices.

Main conclusions

To summarize, it should be noted that the collective protective equipment used is a key condition for preserving the life and health of enterprise employees.

And it is the responsibility of enterprise managers to maintain protective equipment in proper condition; for this, periodic inspections, regular monitoring, technical examinations, etc. must be carried out.

Collective protective equipment is varied, there is no point in memorizing them all, you just need to know what they are, and if necessary, you can always follow GOST 12.4.011-89.

If you still have questions on this topic, you can ask them in the comments, and if you need help in any area of labor protection, please contact us.

Exposure to infrared, electromagnetic, ultraviolet radiation, noise and current

Collective protection means include fencing, warning, sealing devices, protective coatings, devices for cleaning liquids or air, decontamination, sealing, automatic control, control at a certain distance, devices for storing or moving radioactive elements, containers, safety signs. Noise is suppressed thanks to special technology, soundproofing and absorbing coatings. To protect personnel from electric shocks, insulating materials, grounding, control, alarm and automatic shutdown devices are used.

Exposure to static electricity and temperatures

Collective protection means include moisturizing, grounding, shielding devices, neutralizers and anti-electrostatic substances. SPS against low or high temperatures of equipment and air are devices for heating or cooling, signaling, remote control, automatic control, fencing and thermal insulating devices. Mechanical, chemical influences, as well as biological factors are also subject to maximum neutralization.

Remedies for injuries

Injury to employees can occur at any production site. This can be eliminated only by reducing the degree of influence of hazardous factors on humans.

The means of protecting the entire team include the following:

- Ensure that employees are not exposed to exposed live parts. It is necessary to create conditions so that a person in the process of work does not touch moving parts of the equipment, but can use other methods.

- Technical devices must comply with state requirements and be made of durable materials.

- There is no need to create additional dangers during work; even a small burr can cause injury.

- Work must be carried out in such a way that unauthorized persons do not interfere.

It is necessary to provide blocking, fencing and grounding devices in production equipment, and it is not allowed to block passages near it. Can be controlled remotely.

Fire-technical products

Personal and collective protective equipment for workers during fires must be available at every enterprise. According to the relevant order of the Ministry of Internal Affairs, employees have the right to gain access to devices and structures to ensure group safety, as well as special technical devices to prevent fire or maintain life. The safety of people must be maintained while firefighting efforts are being carried out and their health is at risk. Building designs must include fire walls, shelters, windows, doors, as well as locations for fire extinguishing equipment and personal protection for enterprise employees.

Ultrasonic protection

Workers must be protected from exposure to ultrasound-generating equipment

Equipment used in the technological process and generating ultrasound must have the following characteristics:

- Individual choice of power, taking into account all technological requirements.

- During the design process, it is worth noting that the operating frequency should not exceed 22 kHz, this is the only way to reduce the impact of high frequency noise.

- Use of special insulating casings in installations. The structures should not have holes, and special absorbers will be effectively installed in the casing.

- Equipment that produces ultrasound is recommended to be installed in special rooms, and remote control must be provided.

- Locking systems should be installed in equipment if the casing is broken.

- In the process of washing individual parts, automation is used to reduce the ultrasonic level.

- To reduce the degree of ultrasound generated, special devices are made.

- Special handles are installed on the working tool to absorb the sound range of this characteristic.

Means of collective defense against weapons of mass destruction

VCS are engineering structures designed to protect the population. These are the most reliable means of protecting citizens in the event of the use of offensive means, the consequences of which are widespread. Anti-radiation shelters can be used as a shelter.

Means of collective protection against weapons of mass destruction prevent the effects of harmful gases, biological and other toxic substances, high temperatures, and the consequences of nuclear explosions. Such shelters provide several rooms to accommodate people and equipment, as well as ventilation chambers, bathrooms, medical rooms, storerooms, power units and water extraction areas. For the most part, such projects have several exits, closed by an absolutely sealed hatch or door. They are always located in areas where the possibility of collapse is excluded. Capacious structures include vestibules and shafts.

Lecture on life safety on the topic “Means of collective and individual protection of the population”

Topic: Means of collective and individual protection of the population (organization employees).

Questions:

- Collective protective equipment. Actions when sheltering employees of organizations in protective structures. Safety measures when staying in protective structures.

- Individual protection means. Rules for using them.

Collective protective equipment.

Collective protection means (CPF) include civil defense protective structures (shelters, radiation shelters).

Civil defense protective structures (DS GO) are structures designed to protect the population from the damaging factors of modern weapons (ammunition of weapons of mass destruction, conventional weapons), as well as from secondary factors that arise during the destruction (damage) of potentially dangerous objects. Depending on their protective properties, these structures are divided into shelters and anti-radiation shelters. In addition, shelters of the simplest type can be used.

Shelters are created to protect:

- employees of the largest working shifts of organizations located in areas of possible severe destruction and continuing their activities during the period of mobilization and wartime, as well as employees of the working shifts of duty and line personnel of organizations that ensure the life of cities classified as civil defense groups, and organizations classified to the category of special importance for civil defense;

— employees of nuclear power plants and organizations ensuring the functioning and vital activity of these stations;

— non-transportable patients located in healthcare institutions located in areas of possible severe destruction, as well as the medical personnel serving them;

— the working population of cities classified as a special group for civil defense.

Anti-radiation shelters are created to protect:

- employees of organizations located outside zones of possible severe destruction and continuing their activities during the period of mobilization and wartime;

- the population of cities and other settlements not classified as civil defense groups, as well as the population evacuated from cities classified as civil defense groups, zones of possible severe destruction of organizations classified as of particular importance for civil defense, and zones of possible catastrophic flooding.

Actions when sheltering the population (employees of organizations) in protective structures (PS)

The filling of the protective structure is carried out in an organized manner, quickly and without panic. In the shelter, people are placed in groups - in workshops, teams, institutions, houses, streets, marking the appropriate places with pointers. Each group is assigned a leader. Those who arrived with children are placed in separate compartments or in specially designated areas. The elderly and sick are placed closer to the air distribution ventilation pipes.

People must come to the shelter (shelter) with personal respiratory protection equipment, food and personal documents. You cannot bring bulky items, strong-smelling or flammable substances, or bring pets. In the protective structure, it is prohibited to walk unnecessarily, make noise, smoke, go outside without the permission of the commandant (senior), independently turn on and off electric lighting, engineering units, open protective-hermetic doors, and also light kerosene lamps, candles, lanterns. Emergency lighting sources are used only with the permission of the shelter commandant for a limited time in case of emergency. In the shelter you can read, listen to the radio, talk, and play quiet games.

Those being sheltered must strictly follow all orders of the shelter (shelter) management team, comply with internal regulations, and provide all possible assistance to the sick, disabled, women and children. In accordance with safety regulations, it is prohibited to touch electrical equipment, compressed air and oxygen cylinders, or enter the premises where the diesel power plant and filter-ventilation unit are installed. However, if necessary, the commandant or flight commander can attract sheltered people to help troubleshoot engineering equipment and maintain cleanliness and order in the premises.

After filling the shelter, by order of the commandant, the flight personnel close the protective-hermetic doors, emergency exit shutters and exhaust ventilation control plugs, and turn on the filter-ventilation unit to the clean ventilation mode. If the shelter has a vestibule-sluice, its filling can continue even after closing the protective-hermetic doors - using the sluicing method.

To create normal conditions inside the shelter, it is necessary to maintain a certain temperature and humidity. In winter, the temperature should not exceed +10 - +15°C, in summer +25 - +30°C. The temperature is measured with a regular thermometer, holding it at a distance of 1 m from the floor and 2 m from the wall. Measurements are taken in the pure ventilation mode every 4 hours, in the filter ventilation mode - every 2 hours. Air humidity is determined with a psychrometer every 4 hours. Humidity is considered normal not higher than 65 - 70%.

The premises are cleaned twice a day by those being sheltered themselves, as directed by the senior groups. In this case, sanitary facilities must be treated with a 0.5% solution of two-thirds of the basic salt of calcium hypochlorite. The technical premises are cleaned by the personnel of the shelter maintenance unit. Radiation shelters must follow the same basic rules and requirements as shelters.

At national economic facilities and in the residential sector, where the stock of protective structures does not reach the full requirement, the filling of shelters can be carried out with overconsolidation. In this case, people are placed not only in the main compartments, but also in corridors, passages, and airlocks.

In such conditions, the stay in the protective structure should be short. As a result of significant heat generation, increased humidity and carbon dioxide content, people may experience increased temperature, increased heart rate, dizziness and some other painful symptoms. Therefore, it is necessary to limit their physical activity in every possible way and strengthen medical monitoring of their health. There must be a sanitary post in each compartment.

Strict control of the air environment becomes important. If in a shelter the air temperature is below 30°C, the concentration of carbon dioxide does not exceed 30 mg/m3, and the oxygen content is 17% or more, then such conditions are considered normal. When the concentration of carbon dioxide increases to 50 - 70 mg/m3, as well as when the other environmental characteristics mentioned above are exceeded, it is necessary to limit the physical activity of those being sheltered and strengthen medical supervision over them.

Basic rules of conduct in protective structures:

— come to the ZS with your personal protective equipment, food and personal documents;

- take the indicated places in the AP in an organized manner;

— strictly comply with all orders of the personnel of the unit for servicing the equipment;

— maintain calm, prevent cases of panic and violation of public order;

— comply with internal regulations, maintain cleanliness and order in the premises, and carry out cleaning work;

— in the shelter you can read, sleep, listen to the radio, talk, play quiet games;

— carry out work on supplying air to the air defense system by order of the flight commander;

— provide all possible assistance to the sick, disabled, women and children;

- observe safety measures.

The simplest shelters

- these are structures that do not require special construction, which provide partial protection for those sheltered from an air shock wave, light radiation from a nuclear explosion and flying debris of destroyed buildings, reduce the impact of ionizing radiation in radioactively contaminated areas, and in some cases protect from bad weather and other adverse conditions.

Along with trenches and crevices, dugouts, as well as basements, subfloors, cellars, and the interior of buildings can be used as simple shelters. If time and materials are available, these premises are also brought up to the requirements for radiation shelters.

2. Personal protective equipment. Rules for using them

As a result of accidents at production facilities, people may be injured by hazardous chemical, toxic and radioactive substances. To prevent (reduce) the impact on the body of the damaging effects of emergency chemically hazardous, toxic and radioactive substances, personal protective equipment is used.

Personal protective equipment (PPE) is equipment that every person should be able to use, as it is intended to provide first aid in emergency situations.

These include: personal respiratory protection equipment (gas masks, self-rescuers, respirators and simple protective equipment), an individual dressing package (PPI), a personal medical civil protection kit (CIMGZ), an individual anti-chemical package (IPP-8, IPP-11). In addition, it is extremely necessary to have your own home first aid kit.

Personal respiratory protection

Based on the principle of protective action, personal respiratory protection equipment (RPP) is divided into filtering and insulating.

Filter-type RPE includes: gas masks, self-rescuers, respirators and simple protective equipment.

Since the air supplied for breathing in them is cleaned of toxic substances, hazardous substances, radioactive dust and bacterial aerosols, their use is prohibited in cases where:

— the volume fraction of oxygen in the air is less than 18%;

— the air contains hazardous substances, protection from which is not provided for in the operating instructions;

— the concentration of hazardous chemicals in the air exceeds the maximum value provided for in the operating instructions;

— the air contains poorly absorbed organic substances (methane, ethane, butane, ethylene, acitylene, etc.).

Filtering gas masks

Filtering gas masks are designed to protect the respiratory system, eyes and skin of a person from aerosols, vapors and gases of toxic substances (TS) and radioactive substances (RS), biological aerosols (BA).

Modern samples include modernized filtering civilian gas masks GP-7B, GP-7VMB.

But there are other gas masks that can be used, these are GP-7, GP-7V, GP-7VM.

The GP-7V gas mask (Fig. 1) is equipped with a front part of three heights for any size of a person’s face. The mask allows you to negotiate both during direct communication and when working with technical means of communication.

Fig.1. Civil filter gas mask GP-7V

The civilian gas mask GP-7V includes a device for receiving water from a flask while working in a contaminated atmosphere. A flask for drinking water is not included in the gas mask kit, but can be supplied upon customer request.

Before use, the gas mask must be checked for serviceability and tightness. When examining the front part, you should make sure that the height of the helmet-mask corresponds to the required height. Then determine its integrity by paying attention to the glasses of the spectacle assembly. After this, check the valve box and the condition of the valves. They must not be warped, clogged or torn. There should be no dents, rust, punctures or other damage on the filter-absorbing box and neck. Attention is also paid to ensure that the absorber grains do not spill into the box.

The gas mask is assembled as follows: in the left hand, take the helmet-mask by the valve box, and with the right hand, screw the filter-absorbing box with the screw-on neck into the valve box of the helmet-mask until it stops.

Before putting on, the new front part of the gas mask must be wiped inside and out with a clean cloth slightly moistened with water, and the exhalation valves must be blown out. If any damage is detected in the gas mask, they are eliminated; if this is impossible, the gas mask is replaced with a serviceable one.

The assembled, tested gas mask is placed in a bag: a filter-absorbing box is placed on the bottom, and a helmet-mask on top.

The gas mask is carried in the bag. The shoulder strap is thrown over the right shoulder. The bag itself is on the left side, with the flap facing away from you. The gas mask can be in the “traveling”, “ready”, and “combat” positions.

“On the go” - when there is no threat of contamination with chemical agents, hazardous chemicals, radioactive dust, or bacterial agents. Bag on the left side. When walking, it can be moved back a little so as not to interfere with the movement of your arms. The top of the bag should be at waist level and the flap should be closed.

The gas mask is switched to the “ready” position when there is a threat of infection, after information on radio, television or by the command “Get masks ready!” In this case, the bag must be secured with a belt strap, slightly pushed forward, and the valve must be unfastened so that you can quickly use the gas mask.

In the “combat” position – the front part is put on. They do this on the command “Gas!”, according to other orders, and also independently when signs of a particular infection are detected.

The gas mask is considered to be worn correctly if the glasses of the front part are against the eyes and the helmet-mask fits tightly to the face.

The need to exhale forcefully before opening your eyes and resuming breathing after putting on a gas mask is explained by the fact that it is necessary to remove contaminated air from under the helmet-mask if it got there at the time of putting it on.

When wearing a gas mask, you should breathe deeply and evenly. There is no need to make sudden movements. If there is a need to run, then you should start jogging, gradually increasing the pace.

The gas mask is removed by the command “Take off the gas mask!” To do this, you need to lift the headgear with one hand, grab the valve box with the other, slightly pull the helmet-mask down and remove it with a forward and upward movement, put on the headgear, turn out the helmet-mask, wipe thoroughly and put it in the bag. You can remove the gas mask independently (without a command) only if it becomes reliably known that the danger of injury has passed.

When using a gas mask in winter, the rubber may harden (harden), the glasses of the spectacle unit may freeze, the petals of the exhalation valves may freeze, or they may freeze to the valve box. To prevent and eliminate the listed malfunctions, it is necessary, when in a contaminated atmosphere, to periodically heat the front part of the gas mask, placing it over the side of the coat. If the helmet-mask is still frozen before putting it on, you should lightly knead it and, putting it on your face, warm it with your hands until it fits completely to your face. When wearing a gas mask, you can prevent freezing of the exhalation valves by warming the valve box with your hands from time to time, while simultaneously blowing out (with a sharp exhalation) the exhalation valves.

Personal respiratory protection equipment of an insulating type is provided to the personnel of emergency rescue units.

Self-rescuer

- a means of personal protection of the human respiratory system and eyes from toxic combustion products during the declared protective action time during evacuation from industrial, administrative and residential buildings and premises during a fire.

The Phoenix protective hood is designed to protect the respiratory system, eyes and facial skin from combustion products, aerosols, vapors and gases of hazardous chemicals generated during emergency situations in residential, office and industrial buildings and in subway cars or trains, as well as for emergency evacuation from smoke-filled rooms within 20 minutes.

Specifications:

1. Product composition: the hood consists of a front part made of heat-resistant polyamide film in the form of a cap (covering the entire head of a person), a seal made of an elastic white film, a filter-absorbing element measuring 80x300x10 mm, a silicone mouthpiece and a nose clip.

2. The shelf life of the product is at least 5 years in standard vacuum packaging, the weight of the product hood is 90 g.

3. Breathing resistance is insignificant (with an average human breathing rate of 30 l/min, breathing resistance will be 8.8 mm of water column).

4. The heat resistance of the materials corresponds to the purpose of the product and ensures long-term breathing of ambient air with temperatures up to 100°C, and also withstands short-term exposure to sparks of flame.

5. The Phoenix hood protects against more than 30 hazardous chemicals, the main of which are:

- benzene vapors, at concentrations up to 1.2 - 1.3 mg/l (60-65 MAC);

- acrylic acid nitrile vapor at an effective concentration of 0.025 – 0.03 mg/l (50 MAC);

- ammonia, at a concentration of up to 1.2 - 1.3 mg/l (60-65 MAC);

- chlorine, at an effective concentration of 0.05 mg/l (50 MAC);

- hydrocyanic acid, at an effective concentration of 0.03 mg/l (100 MAC);

- phosgene, at an effective concentration of 0.025 mg/l (50 MAC);

- carbon monoxide, at an effective concentration of 0.8-1.0 mg/l (40-50 MAC), with no more than 200 mg absorbed by humans;

- hydrogen sulfide, at an effective concentration of 0.3 mg/l (30 MPC) O;

- sulfur dioxide, at an effective concentration of 0.1 mg/l (100 MAC);

- aerosols (smoke, suspended matter, soot, dust), the total filter permeability coefficient is not more than 5%.

The Phoenix hood must not be used when the oxygen concentration is less than 17% of the volume and the ambient temperature is above 70°C.

Application procedure:

- tear the bag at the notch, remove the “Phoenix” product and unfold it;

- tear the nose clip off the bag;

- stretching the pads, push the clip onto the nose so that it tightly clamps both nostrils;

- insert your hands into the elastic collar and stretch;

- carefully place the hood on your head with the filter facing your face;

- holding your breath, grab the entire mouthpiece with your mouth, supporting the filter with your hand, and hold the inside of the mouthpiece with your teeth throughout the entire time of use. Breathing should be done only through the mouth;

- After use, remove the protective hood.

To quickly transfer the protective hood to a combat position, it is recommended to place it in a pocket or purse and carry it with you at all times.

Respirator

— a means of personal respiratory protection against aerosols (dust, smoke, fog) and/or harmful gases. Respirators are divided into gas-dust-protective, dust-protective, gas-protective and gas-smoke-protective respirators.

The R-2 respirator (Fig. 2) belongs to dust-protective respirators and is designed to protect the human respiratory system from various types of dust:

— radioactive;

- vegetable (hemp, cotton, wood, tobacco, flour, sugar, coal);

- animal (wool, horn, bone, leather, down);

— metal (iron, cast iron, steel, copper, lead);

— mineral (emery, cement, glass, lime, road);

— powdered fertilizers and pesticides that do not emit toxic gases and vapors;

- — dusts of pigments and fertilizers and other types of dust.

Rice. 2. Respirator R-2

The outer shell of the half mask is made of polyurethane foam (a porous synthetic material), and the inner shell is made of a thin airtight film into which inhalation valves are mounted. Between the outer and inner shells there is a filter made of polymer fibers.

The principle of operation of the R-2 respirator is based on the fact that when you inhale, air passes through the entire surface of the shell and the filter is cleaned of dust and enters the under-mask space and respiratory organs through the inhalation valves. When you exhale, air escapes through the exhalation valve. The R-2 respirator is available in 1st, 2nd and 3rd heights.

The respirator does not protect against toxic gases and vapors.

The R-2 respirator provides respiratory protection in both summer and winter conditions.

The simplest means of respiratory protection is a cotton-gauze bandage.

A cotton-gauze bandage can be made as follows: take a piece of gauze 100 cm long and 50 cm wide; in the middle part of the piece, on an area of 30x20 cm, an even layer of cotton wool about 2 cm thick is placed. The ends of the gauze free from cotton wool (about 30-35 cm) are wrapped on both sides, covering the cotton wool, forming two pairs of ties.

When used, apply it to the face so that the lower edge covers the chin, and the upper edge reaches the eye sockets. The lower ends are tied at the crown, the upper ends at the back of the head.

When protecting against chlorine, it is necessary to moisten it with a 2 - 5% solution of baking soda, when protecting against ammonia, with a 2 - 5% solution of citric acid.

Individual medical civil protection kit (CIMGZ)

KIMGZ is intended to provide personnel of formations and the population when they carry out measures to provide first aid to victims performing tasks in areas of possible emergencies.

KIMGZ (Fig. 3) is equipped in accordance with the order of the Ministry of Emergency Situations of Russia dated January 23, 2014 No. 23 and with the order of the Ministry of Health of Russia dated February 15, 2013 No. 70n “On approval of the requirements for the provision of medicines and medical products for the Individual Medical Civil Protection Kit (KIMGP) for the provision of primary health care and first aid."

Rice. 3. Individual medical civil protection kit

The order spells out possible emergency situations for the personnel of the civil defense forces (personnel) and for the population, depending on this, various KIMGZ personnel are staffed.

Compound:

(option 1)

- Device for artificial respiration “mouth-device-mouth” - 1 pc.

- Fabric-elastic hemostatic tourniquet - 1 pc.

- Sterile medical dressing bag - 1 pc.

- Antiseptic napkin made of non-woven material with hydrogen peroxide - 1 pc.

- Hydrogel anti-burn dressing, sterile, with a cooling and analgesic effect (at least 20 cm x 24 cm) - 1 pc.

- Rolled adhesive plaster (at least 2 cm x 5 m) - 1 pc.

- Non-sterile medical gloves, examination - 1 pc.

- Medical non-sterile three-layer mask made of non-woven material with elastic bands or ties - 1 pc.

- Antiseptic napkin made of non-woven material, alcohol - 1 pc.

- Hemostatic sterile dressing with aminocaproic acid (at least 6 cm x 10 cm) - 1 pc.

- Sterile hemostatic dressing agent based on zeolites or calcium and sodium aluminosilicates or calcium hydrosilicate (at least 50 g) - 1 pc.

- Hydrogel dressing agent for infected wounds, sterile, with antimicrobial and analgesic effect (at least 20 g) - 1 pc.

- Non-woven cloth with ammonia solution - 1 pc.

- Ketorolac, tab. 10 mg - 1 tablet.

Individual dressing package

The medical industry produces dressing bags of 4 types: individual, ordinary, first aid with one pad, first aid with two pads.

The individual dressing package is used for applying primary dressings to wounds. It consists of a bandage (10cm x 7m) and two cotton-gauze pads. One of the pads is sewn near the end of the bandage, and the other can be moved along the bandage. Typically, the pads and bandage are wrapped in wax paper and placed in an airtight case made of rubberized fabric, cellophane or parchment paper. There is a pin in the package. The rules for using the package are indicated on the case. When using the bag, take it in your left hand, grab the cut edge of the outer cover with your right hand, jerk off the glue and take out the bag in wax paper with a pin. A pin is taken from the fold of the paper shell and temporarily pinned in a visible place to the clothing. Carefully unroll the paper shell, take the end of the bandage to which the cotton pad is sewn in your left hand, and take the rolled up bandage in your right hand and unroll it. This releases the second pad, which can move along the bandage. The bandage is stretched by spreading the arms, as a result of which the pads straighten.

One side of the pad is stitched with red thread. If necessary, the person providing assistance can touch only this side with their hands. The pads are placed on the wound with the other (not stitched) side. For small wounds, the pads are placed one on top of the other, and for extensive wounds or burns, they are placed side by side. In the case of penetrating wounds, one pad closes the entrance hole, and the second – the exit hole, for which the pads are moved apart to the required distance. Then they are bandaged with circular moves of the bandage, the end of which is secured with a pin.

The outer cover of the bag, the inner surface of which is sterile, is used to apply hermetic dressings. For example, when there is a shot in the lung.

The package is stored in a special pocket of a bag for a gas mask or in a clothing pocket.

An ordinary package, unlike an individual dressing package, is packaged in an outer parchment shell and covered with a parchment parcel.

First aid bags with one and two pads are packaged in a parchment-lined inner shell and a film outer shell.

Each package is accompanied by instructions for opening and consuming it.

Individual anti-chemical package

The individual anti-chemical package IPP-8 is intended for the disinfection of droplet-liquid chemical agents and hazardous chemicals that have come into contact with the human body and clothing, personal protective equipment and tools.

IPP-8 consists of a flat glass bottle with a capacity of 125-135 ml, filled with a degassing solution, and four cotton-gauze swabs. The entire package is in a plastic bag.

When using, you need to open the package shell, remove the bottle and tampons, unscrew the cap of the bottle and moisten the tampon generously with its contents. Using this swab, thoroughly wipe open areas of skin and the helmet-mask (mask) of the gas mask that are suspected of being infected. Moisten the swab again and wipe the edges of the collar and cuff adjacent to the skin with it. When treated with liquid, a burning sensation of the skin may occur, which quickly passes and does not affect well-being and performance.

It must be remembered that the liquid in the package is poisonous and dangerous to the eyes. Therefore, the skin around the eyes should be wiped with a dry swab and rinsed with clean water or a 2% soda solution.

IPP-11 is intended for the prevention of skin-resorptive lesions of chemical agents, hazardous substances (insecticides, pesticides, etc.) through open areas of the skin, as well as for degassing these substances on the skin in the temperature range from -20°C to +50°C.

When applied to the skin in advance, the protective effect lasts for 24 hours.

If there are no anti-chemical bags, drops (smears) of the chemical agent can be removed with paper swabs, rags or a handkerchief. It is enough to treat areas of the body or clothing with plain water and soap, provided that no more than 10-15 minutes have passed since the drops hit the body or clothing. If time is lost, processing still needs to be done. This will somewhat reduce the degree of damage and eliminate the possibility of mechanical transfer of drops and smears of chemical agents or hazardous chemicals to other parts of the body or clothing.

Droplet-liquid chemical agents can also be neutralized using household chemicals. To treat the skin of an adult, you need to prepare in advance 1 liter of 3% hydrogen peroxide and 30 g of caustic soda (or 150 g of silicate glue), which are mixed immediately before use. The resulting solution is used in the same way as the degassing liquid from IPP.

Treatment with PPI or improvised means does not eliminate the need for further complete sanitization of people and disinfection of clothing, shoes and personal protective equipment.

Ventilation

Air supply to the VCS occurs in several modes. Clean ventilation as well as filtration is possible. Restoration of oxygen reserves and the function of complete isolation are provided in shelters built in areas with a high probability of fire. The supply systems for electricity, water, heating, and sewerage are connected to external networks.

The shelters are equipped with portable backup devices in case of malfunction of the main stationary ones, as well as containers for storing water and collecting waste. Heating is carried out through the operation of heating networks. All shelters must be equipped with fire extinguishing equipment, reconnaissance equipment, protective clothing and spare tools.

Regulatory acts on the use of occupational safety equipment

According to Article No. 209 of the Labor Code of the Russian Federation, at all enterprises, along with personal protective equipment for people, it is necessary to use collective protective equipment that is technically related to this production. According to the law, the production manager is responsible for ensuring a safe work process.

Regulatory requirements for the correct organization of working conditions and safety, for state examinations of working conditions at all production facilities are set out in Federal Law No. 90-FZ of June 30, 2006. Federal Law No. 206-FZ of July 24, 2009 describes the rules and standards for safe working conditions, namely, sanitary and hygienic standards, organizational and rehabilitation measures.

Exposure to radiation

Personal and collective protective equipment for workers when an area is contaminated with radiation prevents exposure to ionizing, light radiation, as well as neutron flux, provides shelter from the shock wave, and avoids the entry of toxic and biological substances into the body. For the most part, such shelters are installed in basements. The possibility of quickly constructing shelters from reinforced concrete elements, timber, bricks, stones and even brushwood cannot be ruled out.

All kinds of buried rooms can be converted into anti-radiation shelters. These include cellars, caves, basements, underground workings, and storage for vegetables. The main characteristic of collective protective equipment of this type is the fairly high strength of the walls.

Classification

In the broadest sense, VHCs are divided into:

- Purpose built structures.

- Structures that have been retrofitted (adapted) for shelters or shelters.

- The simplest shelters.

Specially built structures to protect the population include radiation shelters and civil defense shelters.

Adapted or retrofitted shelters include various urban and suburban infrastructure facilities suitable for protecting the population. Natural cavities, mine workings, subways (the most common type), underground passages and transport tunnels are equipped for shelters and shelters. Basements of residential and non-residential buildings, as well as other objects of underground urban space, are equipped with reinforced and anti-radiation shelters.

Increasing the security of the premises

To do this, window and unused doorways are sealed, and a layer of soil is laid on the floors. If necessary, external backfilling of walls protruding above the ground is carried out. Collective protective equipment at the enterprise is specially sealed. Slots, holes or cracks in ceilings and walls, at the outlets of wiring and heating pipes, as well as on window slopes are sealed. The doors are covered with felt or some other dense fabric.

Exhaust and supply ducts are designed for ventilation of rooms with a small area. In buildings adapted for shelter, but not equipped with a water supply system, liquid containers are installed at a rate of 4 liters per person per day. The bathroom is equipped with a cesspool. A portable container or dry closet can be installed. Sun beds, benches and food caches are also installed. An external electrical network provides lighting for such premises.

Retrofitting basements

The safety properties of each collective protective equipment, the use of which, according to the plan, should provide shelter from radiation, can be increased many times due to additional equipment. After the shelter commandant gives the appropriate orders, all sealed doors, emergency exits, and ventilation plugs are closed. The air filtration system is activated. If toxic or noxious substances enter, each shelter occupant must immediately put on personal respiratory protection.

If possible, it is necessary to activate the oxygen filtration unit if there is a fire near the shelter or if there is too much concentration of potent poisons. You will first need to put the shelter into complete isolation mode. Many people think that gas masks are considered collective means of protection. These are individual devices intended for personal use, which should be equipped with each shelter. After the harmful substances have evaporated from the shelter, gas masks can be removed.

Air cleaning

We have already figured out which structures are classified as means of collective protection, now let's find out how normal living conditions are maintained in them. While a person can survive for some time without food and water, he cannot survive without air. Therefore, supplying clean air to the shelter is the most important task in ensuring its habitability.

The air entering the collective protective equipment of workers, military personnel and the general population must be cleaned of mechanical impurities, bacterial agents, as well as radioactive and chemical substances hazardous to humans. For these reasons, stationary shelters are equipped with special filters.

The air is cleaned from mechanical impurities and dust using oil filters of the FYAR type (unified cell filter) and self-cleaning filters of the KD-10 or KD-20 type. It is cleaned from coarse fumes by packaged prefilters of the PFP-100 type. When passing through the filter, mechanical particles settle on an oil-lubricated mesh or filter bag. Periodically clogged filters are replaced with clean ones. In self-cleaning filters, the oil is changed, and in pre-filters, filter bags are changed. The level of filter clogging is reflected by their aerodynamic resistance, measured in millimeters of mercury.

The design of the FNR is quite simple - a box-shaped body in which 12 metal corrugated meshes are installed. PFP-1000 is not much more complicated - a housing with a filter package. The filter package consists of 4 cassettes. Each cassette is a rectangular metal frame in which folded filters made of a special material are fixed.

The pre-filter works in this way: clogged air is supplied to the housing through the inlet, cleared of dust, smoke and fog by passing through the filter sections, and finally exits through the outlet into the pipeline. Through the pipeline, air is supplied to absorbent filters, in which the next stage of cleaning occurs.

Absorber filters clean the air from radioactive dust, bacterial aerosols, toxic fumes and other toxic substances. For this purpose, filters of the FP type, models “50/25”, “100/50”, “200” and “300”, as well as the FPU type, models “200” and “300” are used. Today, the production of environmental filters of the FE type has also been established, which purify the air from sulfur oxides, hydrogen sulfide vapors, hydrogen chloride, chlorine, dichloroethane, alcohols, phosgene and various aerosols.

The shelter, which is classified as a collective means of protecting the population, has bathrooms, catering facilities and other auxiliary premises. In these rooms, special filters with increased capabilities are used. For example, marine mine filters (MSF) are installed in the ventilation systems of bathrooms. They purify the air from hydrogen sulfide vapor, nitrogen oxides, sulfur dioxide, methanol and other substances.

Simple shelters

What means of collective protection can be classified as the simplest? These are open or covered gaps that can be constructed using available materials. The protective properties of the simplest shelters are very reliable. Thanks to their use, penetrating radiation, shock waves, and light radiation cause less damage. The level of radiation and the effect of biological and toxic substances on the skin is reduced.

Slots are built in areas where the possibility of blockages or flooding by rain and melt water is excluded. First, open structures are created. These are trenches in the form of a zigzag, consisting of several sections more than 15 meters in length. The depth is up to 2 meters, and the width is approximately 1 meter. This shelter is designed for 50 people. Before constructing a gap, it is necessary to mark its plan on the ground.

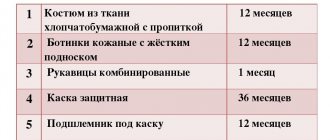

Rules for providing PPE at enterprises

The main legal act defining the procedure for providing workers with PPE is the Rules for providing workers with special clothing, special shoes and other personal protective equipment

, approved by Decree of the Ministry of Labor and Social Development of Russia dated December 18, 1998 No. 51. The rules provide for the provision of PPE according to Standard Standards, regardless of which sector of the economy the production belongs to, and also regardless of the form of ownership of organizations.

In some cases, in accordance with the characteristics of production, the employer may, in agreement with the state labor safety inspector and the relevant trade union body or other representative body authorized by the employees, replace one type of personal protective equipment provided for by the Standard Industry Standards with another that provides complete protection from dangerous and harmful production conditions. factors: overall can be replaced with a cotton suit or robe and vice versa, suit with overalls with a shirt (blouse) or a sundress with a blouse and vice versa, a can be replaced with a cotton suit with fire-retardant or acid-proof impregnation and vice versa, a suit can be replaced with a cotton suit with fire-retardant impregnation or water-repellent impregnation and vice versa, boots ( low boots ) - with rubber boots and vice versa, boots ( low boots ) - with tarpaulin boots and vice versa, boots - with tarpaulin boots and vice versa, a rubberized apron - with an apron made of polymer materials and vice versa, mittens - with gloves and vice versa , gloves - with gloves made of polymeric materials and vice versa, vachegi - with heat-resistant gloves made of synthetic material and vice versa, plastic oversleeves - with oversleeves made of polymeric materials and vice versa. In cases where such personal protective equipment as vest , a safety belt, dielectric galoshes and gloves , a dielectric rubber mat safety glasses and shields , a respirator , a gas mask, a protective helmet , a helmet, shoulder pads , elbow pads, self-rescuers, antiphons, plugs, noise-proof helmets, light filters, vibration-proof gloves and others are not specified in the Standard Industry Standards, the basis for the issuance of which is the certification of workplaces depending on the nature of the work performed with a wear period - until worn out or as duty workers and can be included in collective agreements and agreements. The employer is obliged to replace or repair PPE that has become unusable before the end of the wear for reasons beyond the employee’s control.